(PDF) Thin-Film Solar Cells: An Overview

Mar 1, 2004 · Schematic cross-sectional diagram of a thin-film photovoltaic module (adopted from Reference 10) Figures - uploaded by Puthur Paulson

Thin Film Solar Panels and Their Structural Benefits

May 23, 2025 · Discover why thin film solar panels are ideal for modern buildings—lightweight, versatile, efficient in low light, and requiring expert

Thin-Film Solar Panels: Technologies, Pros

Feb 7, 2024 · Thin-film solar technology includes many features that make it unique for particular applications that are not suited for traditional c-Si PV

ZSW: Thin-film solar cells and modules

The manufacture of thin-film modules therefore differs fundamentally from the manufacture of silicon-based technology. Solar modules with already

Thin-film solar panels: what you need to know

Feb 12, 2023 · There are many different types of thin-film modules, built using a variety of materials and processes. In this article, we''ll review the four major types of thin-film

Thin-film solar panels: explained [UK, 2025]

Jul 25, 2025 · What are thin-film solar panels? Thin-film solar panels, also known as flexible solar panels or stick-on solar panels, are a type of photovoltaic (PV)

Copper Indium Gallium Diselenide Solar Cells | Photovoltaic

Apr 3, 2025 · CIGS-based thin-film solar modules represent a high-efficiency alternative for large-scale, commercial solar modules. CIGS is a versatile material that can be fabricated by

Solar Photovoltaic Cell Basics

May 13, 2021 · Measured on an annual basis, the thin-film PV company. The Plant adopts a new installation method, with module generates 10% more power than the crystalline the power

Everything You Need To Know About Thin-Film

Thin-film solar panels are made of very thin layers of photovoltaic materials, making them extremely lightweight and sometimes even flexible. You''ll find

Solution-Processed Thin Film Transparent Photovoltaics:

Oct 23, 2024 · Recent advancement in solution-processed thin film transparent photovoltaics (TPVs) is summarized, including perovskites, organics, and colloidal quantum dots. Pros and

Types of photovoltaic solar panels and their

Nov 6, 2017 · Increased degradation : The lifespan of thin film panels may be shorter compared to crystalline ones. Thin-film panels are especially useful in

Thin Films Photovoltaics

Oct 8, 2023 · Thin film photovoltaic-based solar modules produce power at a low cost per wat. They are ideal candidates for large-scale solar farms as well as building-integrated

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · Thin film solar cells are favorable because of their minimum material usage and rising efficiencies. The three major thin film solar cell technologies include amorphous silicon

What is Thin Film Photovoltaic Module?

Nov 17, 2023 · The solar module is not just 1 micron thick. In fact, each solar system is composed of multiple layers of thin film. Solar thin-film panels are about 350 times thinner than mono or

Understanding the Composition of Solar Panels

Apr 7, 2023 · Thin film solar cells, also known as photovoltaic (PV) cells, are an alternative to traditional crystalline silicon-based solar cells. These cells are

An Overview Of Thin Film Solar Panels

Apr 29, 2025 · Thin film PV modules can be made lightweight, bendable, and even transparent, enabling integration into various surfaces and applications.

Progress in Thin-Film Photovoltaics: A Review of

Mar 20, 2025 · Thin-film solar cells (TFSCs) represent a promising frontier in renewable energy technologies due to their potential for cost reduction,

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · Under the laboratory condition, life-testing of thin-film modules shows that the degradation of these cells are faster compared to conventional PV, though the expected

Thin-Film Solar Panels

Feb 27, 2021 · B. How Thin-Film Solar Cells are Made? Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts:

Mechanical properties of

May 21, 2024 · Introduction The use of EVA as an encapsulation material for photovoltaic modules as shown in Fig. 1, dates back to the Flat Plate Solar Array Project at the Jet

About CIGS – CIGS Thin-Film Photovoltaics

As of 2019, CIGS cell efficiencies have surpassed all other thin film PV technologies, achieving 23.35% on the cell and 17.5% on the module level. CIGS has also been deployed in ultra-high

Understanding the Composition of a Solar Cell

Jun 1, 2021 · Thin-film PV devices are module-based approaches to cell design. A thin-film module is a module-level PV device with its entire substrate coated in

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Types of Solar Panels: Present and Future of

Aug 1, 2022 · Monocrystalline module manufacturing involves crystal formation, which results in a higher cost and even wastage to some extent. Likewise, a

What Are CIGS Thin-Film Solar Panels? When to

Mar 6, 2022 · Thin-film solar panels are among the most advanced and efficient power generation technologies created for the solar industry. These

Everything You Need To Know About Thin-Film

Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials. These thin, light-absorbing layers can

Different types of Solar Panels: Monocrystalline, Polycrystalline, Thin

Feb 5, 2024 · Discover the differences between monocrystalline, polycrystalline, thin-film, bifacial, concentrated PV, and building-integrated solar panels. Learn about their efficiency, cost,

Thin-Film Solar Panels: An In-Depth Guide

Mar 12, 2022 · Thin-film solar panels are manufactured using materials that are strong light absorbers, suitable for solar power generation. The most

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

A review of toxicity assessment procedures of solar photovoltaic modules

Feb 15, 2024 · This paper provides an overview of the metal composition of PV modules and common procedures for toxicity assessment through extensive research and review of

First Solar | Series 7 TR1 505-540W | Solar Panel

First Solar Strengthens Global Technology Position in PV with Acquisition of Evolar First Solar Achieves Yet Another Cell Conversion Efficiency World

Thin-film solar panels: What you need to know

Feb 13, 2023 · Thin-film modules use one of the following four technologies: cadmium telluride (CdTe), amorphous silicon (a-Si), copper indium gallium selenide (CIGS), and organic

Thin Films

Dec 12, 2024 · Please see the lecture 13 video for additional structure visual, or see Fig. 1 in Klein, A., et al. "Interfaces in Thin Film Solar Cells."Record of the 31st IEEE Photovoltaic

Thin-film solar panels: what you need to know

Feb 12, 2023 · In this article, we''ll review the four major types of thin-film photovoltaic panels — amorphous, cadmium telluride (CdTe), copper gallium indium diselenide (CIGS), and organic

Thin Film Deposition Technologies and

Nov 29, 2022 · Renewable energy will play a critical role in reducing emissions to mitigate climate change. Photovoltaic (PV) is one of the most promising and

In-depth understanding of the composition of photovoltaic modules

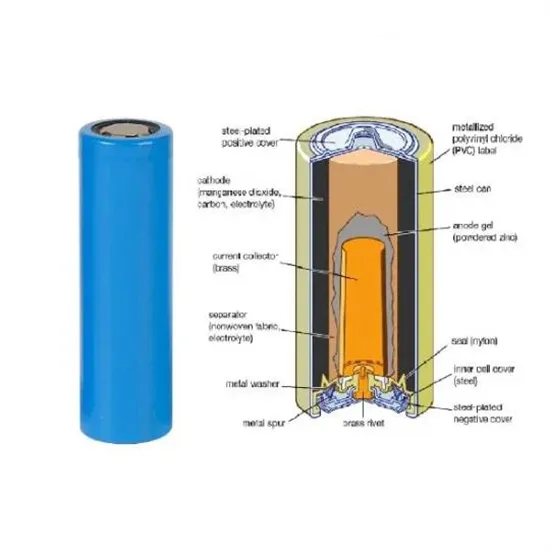

Photovoltaic modules are mainly composed of the following parts: Battery Cells Battery cells are the core components of photovoltaic modules, and their function is to directly convert solar

6 FAQs about [Photovoltaic thin film module composition]

What is a thin-film solar cell?

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main types of thin-film PV semiconductors on the market today: cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS).

What materials are used for thin-film solar technology?

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium arsenide (GaAs). The efficiency, weight, and other aspects may vary between materials, but the generation process is the same.

What are the different types of thin-film solar panels?

There are four main types of thin-film solar panels: amorphous, cadmium telluride, copper gallium indium diselenide, and organic solar panels. Amorphous solar panels are more flexible but less efficient than other types of thin-film solar panels. Cadmium telluride (CdTe) is the most popular material for manufacturers of thin-film solar panels.

What are the different types of thin-film PV semiconductors?

There are two main types of thin-film PV semiconductors on the market today: cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS). Both materials can be deposited directly onto either the front or back of the module surface.

What is a thin-film PV device?

Thin-film PV devices are module-based approaches to cell design. A thin-film module is a module-level PV device with its entire substrate coated in thin layers of semiconductor material using chemical vapor deposition techniques and then laser-scribed to delineate individual cells and make electrical connections between cells.

What are the new thin film PV technologies?

Emerging next generation thin film technologies With intense R&D efforts in materials science, several new thin-film PV technologies have emerged that have high potential, including perovksite solar cells, Copper zinc tin sulfide (Cu 2 ZnSnS 4, CZTS) solar cells, and quantum dot (QD) solar cells.

Industry Information

- Battery price for Havana communication base station

- Hsx energy storage power supply

- Swaziland Communications 5G Indoor Base Station

- How much loss does the photovoltaic panel have through the glass

- Lithium battery storage voltage

- Manama smart energy storage battery custom manufacturer

- Containerized generators at favorable prices

- Yamoussoukro flashlight lithium battery pack

- 48 to 220 inverter

- Solar photovoltaic panels can insulate

- What to do if the communication base station loses power

- The relationship between RV and portable power supply

- 3 6 kw solar inverter factory in Nepal

- Mexican grid-connected photovoltaic solar panels

- Where can I buy assembled battery cabinets in Brunei

- 7v solar panel 20 watts

- 12v100v inverter

- Battery energy storage prices in Ho Chi Minh City Vietnam

- Roman Lithium Energy Storage Power Supply Specifications

- High quality hybrid inverters in Tunisia

- The Vatican recommends using batteries for energy storage

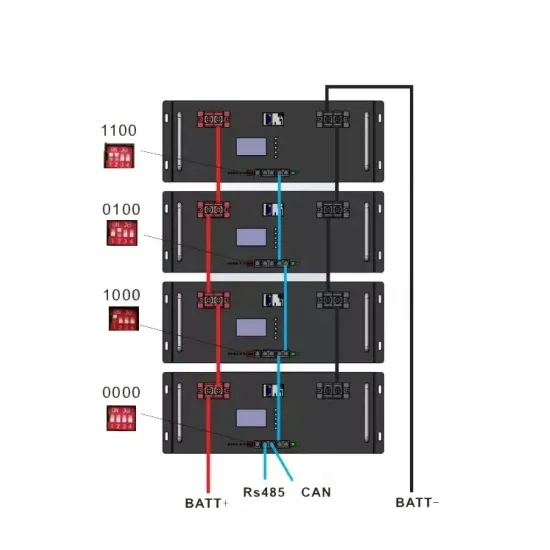

- Fire protection usp host and battery cabinet

- Inverter prices in Canada

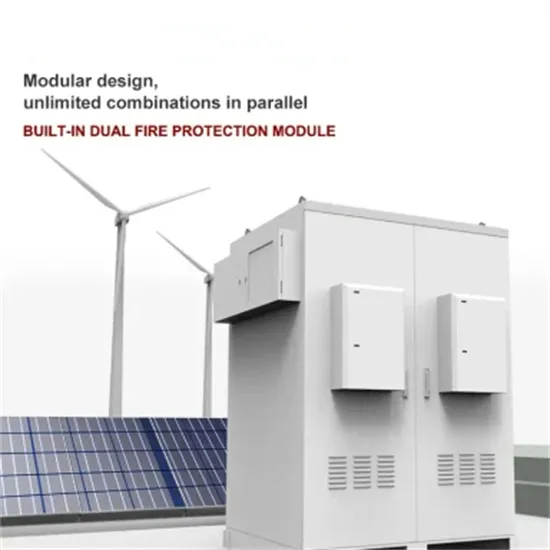

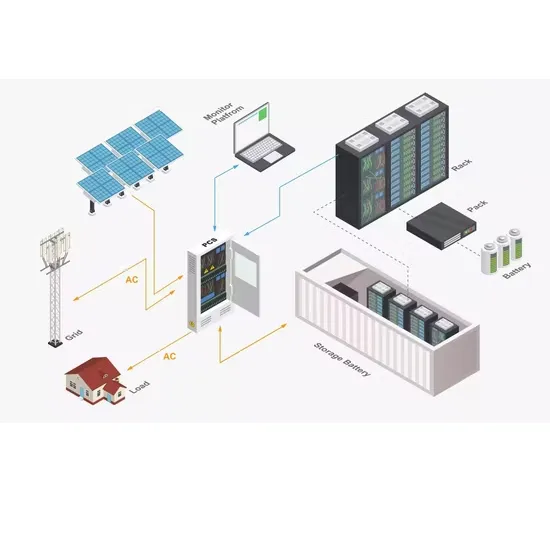

Commercial & Industrial Solar Storage Market Growth

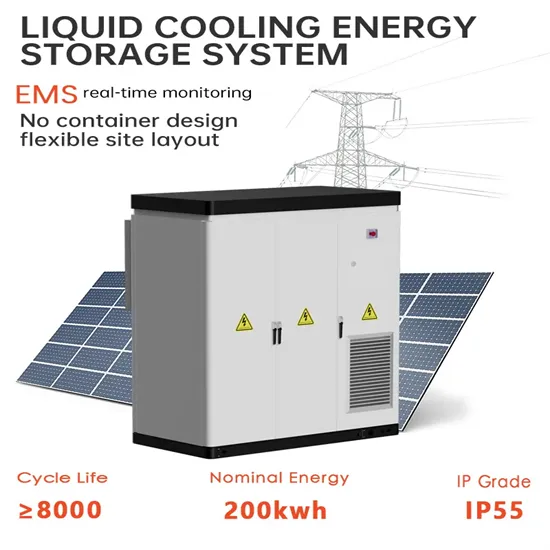

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.