Aluminum electrolytic capacitors

May 18, 2024 · Materials and chemicals used in our aluminum electrolytic capacitors are continuously adapted in compliance with the TDK Electronics Corporate Environmental Policy

Electrolytic capacitor: Properties and operation

Feb 1, 2023 · Electrolytic capacitors are among the components whose lifetime has the greatest influence on the reliability of electrical systems. Over the past three decades, many efforts in

Aluminum Electrolytic Capacitors | Nichicon

Aluminum Electrolytic Capacitors Nichicon is widely acknowledged as a global leader in aluminum electrolytic capacitors. We produce a wide range of capacitors that deliver exceptional

Aluminum Electrolytic Capacitors

Jul 28, 2025 · The advantages of aluminum electrolytic capacitors that have led to their wide application range are their high volumetric efficiency (i.e. capacitance per unit volume), which

Aluminum Electrolytic Capacitors for Industrial

Jan 28, 2022 · Aluminum Electrolytic Capacitors TDK Foil Italy/ Iceland (production of aluminum foil for Electrolytic Capacitors) TDK benefit Three capacitor factories on three continents and

Capacitors | Vishay

4 days ago · Types of capacitors manufactured by Vishay include tantalum (both solid and wet), ceramic (both multilayer chip and disk), film, power, heavy-current, and alumninum. Vishay is

al-all-e1001l-110701

Sep 9, 2021 · 1-1 Basic Model of Aluminum Electrolytic Capacitors Capacitors are passive components. Among the various kinds of capacitors, aluminum electrolytic capacitors offer

Aluminum Capacitors

6 days ago · KEMET aluminum electrolytic capacitors offer excellent ripple current carrying capability coupled with extended life for high energy and power

Aluminium Electrolytic Capacitors

Exxelia aluminum electrolytic capacitors deliver not only high capacitance values (up to 2.2F) and extended service life but also thrive under extreme

Aluminum Electrolytic Capacitors

Aluminum Electrolytic Capacitors An electrolytic capacitor is a type of polarized capacitor that uses a wet electrolytic solution and an oxide film to store

Capacitors | Passive Components | Würth

Wide range of capacitors in various types from Würth Elektronik | Best quality | Fast delivery | Free Eagle & Altium Libraries

ALUMINUM ELECTROLYTIC CAPACITORS

Jianghai manufactures radial electrolytic capacitor series, which are characterized by their compact design and a large number of possible connection assemblies. With a temperature

ALUMINUM ELECTROLYTIC CAPACITORS TECHNICAL

Oct 7, 2003 · TECHNICAL NOTE Structure of aluminum electrolytic capacitors The aluminum electrolytic capacitor is mainly composed of a inside element, which is made up of an anode

Exploring Aluminum Electrolytic Capacitor Types

Feb 4, 2024 · Explore various aluminum electrolytic capacitor types, their electrical characteristics and diverse applications.

Technical Guide

May 22, 2016 · 1. Introduction Capacitor is electronic component constructed electronic circuit. There are a variety of capacitors which have various materials and construction. Typical

aluminium electrolytic capacitor, conductive

Shanghai Yongming electronic company established in 2001, is a leading manufacturer in providing and selling diversified aluminum electrolytic

aluminium electrolytic capacitor, conductive

Shanghai Yongming electronic company established in 2001, is a leading manufacturer in providing and selling diversified aluminum electrolytic capacitors.

Professional Electrolytic Capacitor Manufacturer

Beryl is a professional capacitor manufacturer with 18 years of R&D experience in electrolytic capacitors, super capacitors, and so on.

Aluminum Electrolytic Capacitors

Jul 18, 2019 · Aluminum Electrolytic Capacitors Aluminum Capacitors are capacitors that are composed of two rolled up strips of aluminum foil with a

High-performance MIM-type aluminum electrolytic capacitors

Aug 1, 2024 · Abstract Capacitors are indispensable components of electronic circuits. Filter capacitors, mainly dominated by electrolytic capacitors, are critical for the accurate power

Aluminum Electrolytic Capacitor Application Guide

Sep 17, 2018 · Aluminum electrolytic capacitor construction delivers colossal capacitance because etching the foils can increase surface area more than 100 times and the aluminum

The engineer''s guide to aluminum electrolytic

Mar 4, 2024 · What is an aluminum electrolytic capacitor? Aluminum electrolytic capacitors, often called electrolytic capacitors, are usually selected because

Electrolyte evaluation and engineering for the

High power density and long cycle life are the two most prominent properties of ECs, thanks to the electrostatic nature of their charge storage mechanism. These properties are well utilized in a

Yunxing Aluminum Electrolytic Capacitors

Yunxing specializes in manufacturing aluminum electrolytic Snap-in and polymer capacitors,Products cover LED lighting,charger,adaptor,audio amplifier

aluminium electrolytic capacitor, conductive polymer aluminium

Supercapacitors are high reliability, high power, ultra-high capacitance energy storage devices utilizing electric double layer capacitor (EDLC) construction. An Supercapacitor modular is

Keltron Supercapacitors

Sprague Electromag, Belgium for manufacture of Aluminium Electrolytic Capacitors. KCCL went into commercial production on 19th August 1978.

Supercapacitor Technical Guide

Feb 23, 2024 · The life expectancy of supercapacitors is similar to aluminum electrolytic capacitors. The life of supercapacitors will double for every 10°C decrease in temperature or

Sweden Aluminium Electrolytic Capacitors Market Boom:

Jul 14, 2025 · Key Insight: Sweden is forecasted to grow at 6.4% CAGR in the aluminium electrolytic capacitors market due to rising automation, clean energy mandates, and a strong

High energy density MIM-type aluminum electrolytic capacitors

May 1, 2025 · The common types of capacitors include film capacitors, ceramic capacitors, and solid aluminum (or tantalum) electrolytic capacitors [4]. Film capacitors currently dominate high

Aluminum Electrolytic Capacitors

Apr 2, 2025 · Understanding aluminum electrolytic capacitors: types, characteristics, and behavior. Explore their self-healing properties.

6 FAQs about [Swedish Gothenburg super aluminum electrolytic capacitor]

Why do aluminum electrolytic capacitors have colossal capacitance?

Aluminum electrolytic capacitor construction delivers colossal capacitance because etching the foils can increase surface area more than 100 times and the aluminum-oxide dielectric is less than a micrometer thick. Thus the resulting capacitor has very large plate area and the plates are intensely close together.

How are the materials and chemicals used in our aluminum electrolytic capacitors adapted?

Materials and chemicals used in our aluminum electrolytic capacitors are continuously adapted in compliance with the TDK Electronics Corporate Environmental Policy and the latest EU regulations and guidelines such as RoHS, REACH/SVHC, GADSL, and ELV. MDS (Material Data Sheets) are available on our website for all types listed in the data book.

Who makes Radial electrolytic capacitors?

Jianghai manufactures radial electrolytic capacitor series, which are characterized by their compact design and a large number of possible connection assemblies. With a temperature resistance of up to +135 °C and a maximum cup diameter of 25 mm, the durable capacitors offer excellent solutions for many applications.

Who makes screw terminal electrolytic capacitors?

As one of the largest manufacturers of screw terminal electrolytic capacitors, Jianghai produces a wide range of can dimensions and a large selection of screw terminals.

What is an aluminum electrolytic capacitor?

As is the case with all capacitors, an aluminum electrolytic capacitor comprises two electrically conductive material layers that are separated by a dielectric layer. One electrode (the anode) is formed by an aluminum foil with an enlarged surface area. The oxide layer (Al2O3) that is built up on this is used as the dielectric.

What is a high voltage electrolytic capacitor?

With high-voltage aluminum electrolytic capacitors rebound voltages of 40 to 50 V are possible. While such voltages are not frightening distraction if the terminals are shorted by a tool during installation. Conductive tape and wire shorting straps can be supplied for the faint of heart. The tradeof is extra cost and the labor to remove them.

Industry Information

- Mongolian local inverter manufacturer supply

- Which photovoltaic curtain wall has good quality

- Ankara wind power grid-connected inverter

- Photovoltaic energy storage cabinet lithium battery group agent

- Capacity of one energy storage battery

- Laayoune container silent generator set

- Independent energy storage power station in Africa

- Technical requirements for energy storage cabinets

- Sana EK Energy Storage Product Application

- Solar panel photovoltaic panel brand

- Ouagadougou Energy Storage Battery

- What is the steady-state mode of photovoltaic inverter

- Tri-proof solar energy site energy prices

- Factory price 480v switchgear in Czech-Republic

- New Energy Storage Company in Yaoundé

- Wholesale 200w power inverter in Mozambique

- Huawei Tajikistan Outdoor Power Supply

- The price of lithium batteries for energy storage in Freetown

- How much does 150kw energy storage cost

- What is the appropriate size of RV energy storage battery

- Montevideo Solar Pressure Container Customization

- Venezuela emergency energy storage vehicle equipment

- How to build wind power stations for communication base stations

Commercial & Industrial Solar Storage Market Growth

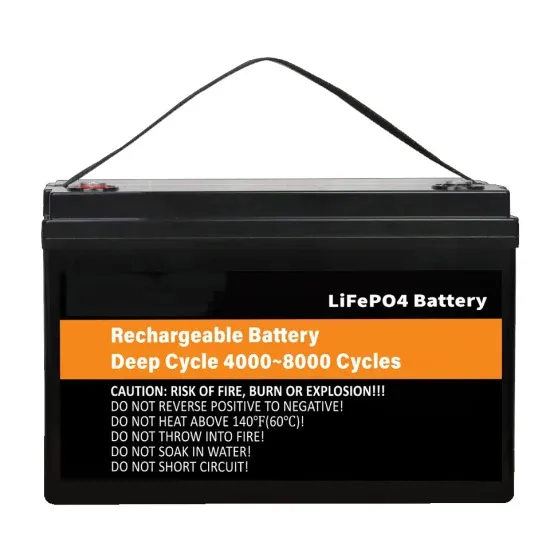

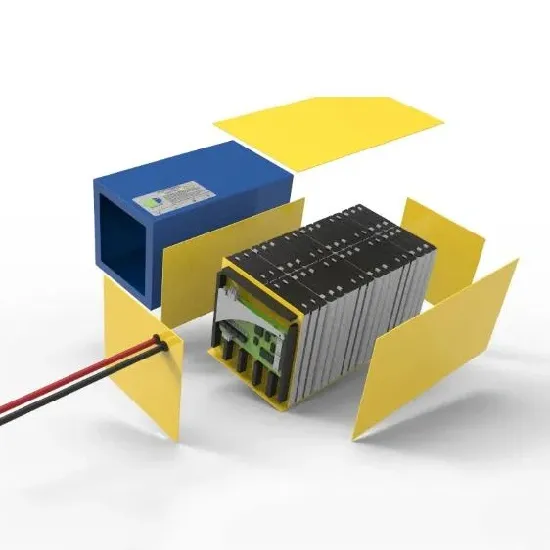

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.