14: Coal-based Oil, Gas and Chemical

Ziyao Xu, Jijian Lian, Jinliang Zhang and Lingling Bin, "Investigating and optimizing the water footprint in a typical coal energy and chemical base in

Construction Started for the Main Plant of ChinaCoal Yulin Coal

Jul 8, 2024 · This project is the first coal chemical project approved by the State Ministry of Ecology and Environment after China set the "peaking carbon emissions and achieving carbon

ChinaCoalChem

Nov 30, 2022 · Besides, Shaanxi Coal Yu-Shen coal species gradient conversion to chemical new material (phase II) demo project, Weinan Pucheng Clean Energy Company CTO (phase II)

Transforming coal chemical industry to unleash

6 days ago · Operated by CHN Energy Yulin Chemical Co Ltd, a subsidiary of China Energy Investment Corp, the major clean coal production base is

Reviews of clean coal conversion technology in China: Situations

Jul 1, 2021 · It is important to develop the advanced coal to chemicals industry (ACCI) against a backdrop of coal-based energy structures, excessive imported oil and natural gas, and strict

Shaanxi Coal held a super project design kick-off

May 15, 2023 · Recently, the 15 million tons/year coal separation, clean and efficient conversion demonstration project of olefins, aromatics and deep

Electricity Generation and By-products | ND

Aug 15, 2025 · Electricity Generation and By-products The chemical energy stored in coal is released when it is burned and changed to thermal (heat)

''Green'' hydrogen boosting coal-to

Sep 20, 2023 · Base reduces pollution caused by traditional working practices. Hou Liqiang reports from Beijing, with Hu

The Processed Coal Manufacturing Process: A

Processed coal manufacturing encompasses a range of methods and technologies used to extract, process, and convert coal into various forms for

China Coal Yulin Coal Deep Processing Base Project Starts

The project is not only committed to the high-end, diversified and low-carbon development of coal chemical industry, but also focuses on the coupled development of coal, coal-fired power and

Coal Chemistry Industry: From Production of

Oct 10, 2023 · Coal resources are one of the key energy sources and essential for modern economic development. Despite the traditional coal industries having

Hualu Engineering Technology Co Ltd

The "Demonstration Project of New Chemical Materials Production via Coal Quality-based Utilization" of Yulin Chemical Co., Ltd. is a key large-scale coal

ASIACHEM Consulting

Aug 7, 2024 · The new edition of 2024 adds a new section of Carbon neutrality (CCUS & Coal chemical coupling new energy, green electricity, green hydrogen, green methanol, green

Sinopec China Coal Yulin EPC general

On August 21, 2024, the key components of the China Coal Yulin coal deep processing base project: the EPC general contracting project launch

Prospects of the Chinese coal chemical industry in an

Feb 22, 2024 · dual carbon goals in September 2020, the attitude of the coal industry is more supportive. In June 2021, CNCA recommended further capacity expansion of the Chinese

2023 Coal Chemical Industry High Quality Development

2、 Main content of the conference and proposed invited experts (1) 2023Conference on High Quality Development of Coal Deep Processing (Coal Chemical) Industry 1.Reflection on

Coal as the world''s dominant energy source and its role in the energy

Coal-fired power plants account for about 20 % of these emissions. Moving away from coal as an energy fuel is an international priority in industrialized countries. Governments are seeking to

Coal-Fired Power Station

The higher the ratio of electrical energy output to chemical energy input of the coal combustion process, the cheaper each unit of electricity produced will be.

Eliminating environmental impact of coal mining wastes and coal

Oct 1, 2024 · The aim of this process concept is to minimise the volume and environmental impact of coal mining wastes and coal processing by-products as well as coal mine VAM while being

Huanneng Longdong Energy Base Launches World''s Largest

Sep 22, 2023 · Relying on the construction of the Zhengning 2x1000 MW peak-load coal-fired power project within the base, it utilizes a post-combustion chemical absorption route to

China Coal Yulin Coal Deep Processing Project

On August 16, 2024, China Coal Yulin Coal Deep Processing Base, a subsidiary of China Coal Shaanxi Energy and Chemical Group, held a grand launch

China Coal Yulin Coal Deep Processing Base Project Starts

With a total investment of 23.888 billion yuan, it will build facilities with an annual output of 2.2 million tons of methanol and 900,000 tons of polyolefins, and upgrade the existing first-phase

Coal chemical industry and its sustainable development in

Nov 1, 2010 · The coal chemical industry will play an important role in the sustainable development of China''s energy resources in the next twenty years, which will alleviate

ASIACHEM Consulting

Apr 22, 2022 · The project is a Shaanxi Province coal chemical industry carbon emission environment impact evaluation trial, and contracted to carry out two energy

Tech-Type: Coal-Fired Power Stations

Jan 21, 2025 · Coal-fired power plants convert chemical energy stored in coal into electrical power through various technological configurations. Here''s a comprehensive overview: Tampa

Coal fired power plant

Aug 3, 2025 · Figure 1. A coal fired power plant in England. [1] Note the two tall smoke stacks where the combustion products go into the atmosphere and the

Construction of a Coal Chemical Industry Park with Zero

Aug 20, 2024 · This paper proposes four scenarios for using the flue gas CO 2 from a 300-MW coal-fired power plant in a coal chemical park as a functional unit, including CO 2

Visiting the world''s biggest single coal-to-liquid

Jul 20, 2017 · The SNCG''s main business lies in coal mining, washing and processing. They started work on coal to chemicals with its coal-to-methanol

Shaanxi''s largest coal chemical project design

May 26, 2020 · The largest existing coal chemical project is Yulin City, Shaanxi Province. The Shaanxi Coal Yulin Chemical Coal Quality Clean and Efficient

Baofeng energy''s surge in performance: What Lies Behind

Jun 16, 2025 · 4. Yanchang Petroleum Coal Chemical Project Yanchang Petroleum has established a large coal-to-olefins base in Yulin, focusing on downstream deep processing of

Hybrid Energy System Proposed for a Coal-Based Chemical

Recently, a joint research team from CAS Key Laboratory of Low-Carbon Conversion Science & Engineering of Shanghai Advanced Research Institute (SARI) and SARI-ShanghaiTech

China Coal''s subsidiary to build coal deep processing base

China Coal announced on April 27 that China Coal Shaanxi Yulin Energy and Chemical Co., Ltd., a wholly-owned subsidiary of the company, plans to invest in the construction of China Coal

Photovoltaic Systems of Ningdong Renewable

Jul 3, 2023 · As a typical demonstration project of CHN Energy, the project is part of efforts made by the company to achieve the country''s carbon peak and

CHN Energy''s East Ningxia Chemical Industry and Energy Base

Jun 24, 2024 · Ranking first in CTL and aramid production capacity and second in green hydrogen production capacity in China, and contributing more than one-fifth of the country''s coal-based

12.3. Types of Coal-derived Chemicals

Aug 20, 2025 · The processes for production of specific chemicals from gasification-derived syngas are typically proprietary systems using specialized

6 FAQs about [Coal chemical energy processing base station]

What is the estimated investment for coal chemical industry project?

It has been completed in It was completed and put into production in July 2014. The estimated investment for the second phase of the coal chemical industry project is 23.888 billion yuan. It will build a coal-based raw material with an annual output of 2.2 million tons of methanol and 900,000 tons of olefins and related supporting facilities.

Can CO2 be used as a functional unit in a coal chemical park?

This paper proposes four scenarios for using the flue gas CO 2 from a 300-MW coal-fired power plant in a coal chemical park as a functional unit, including CO 2 hydrogenation to methanol scenario, CO 2 -ammonia synthesis to urea scenario, and scenarios of zero carbon coal chemical park’ scenario based on methanol or urea.

Where are coal chemical projects located in China?

coal chemical projects in China are located in the top four coal-producing provinces, with24 per cent in Inner Mongolia, 18 per cent in Shaanxi, 15 per cent in Xinjiang, and 7 per cent in Shanxi,33 a phase-down of coal chemical manufacturing needs to proactively consider how altern ntly improve technolog

Where are China's most important coal projects located?

ts. Meanwhile, coal chemical projects are mainly located in water-stressed western regions. In particular, while Yulin in Shaanxi and Ordos in Inner Mongolia are two of China’s most important

What is coal based chemical industry?

glycolCoal-to-GasCoke oven gasCokingCokeCalcium carbide ovenAcetylene-based chemicalsIn the Chinese context, the traditional coal chemical industry mainly consists of coke manufacturing, coal to ammonia and urea, and coal to polyvinyl chloride (PVC) via calcium carbide (CaC2) manufacturing—uses of coal as raw ma

How does China's energy sector benefit coal chemical development?

er, the industrial structure of China’s energy sector benefits coal chemical development. State-owned enterprises dominate the Chinese fossil fuel industry, and account for almost all national oil and gas output as well as three quarters of revenue of the coal industry.27 Not surprisingly,

Industry Information

- Kampala Energy Storage Photovoltaic Exhibition

- User-side energy storage power station

- Battery and inverter connection

- Energy storage mobile charging pile in Penang Malaysia

- Cameroon produces photovoltaic energy storage integrated machine

- Ljubljana dedicated energy storage battery manufacturer

- Prague portable power bank manufacturer

- China Communications 5G Base Station Density

- Home energy storage 50kv

- What should we pay attention to when using photovoltaic glass

- Tajikistan home energy storage system manufacturer

- 99 8mw battery energy storage station project overseas project

- Koten safety breaker in China in Slovakia

- Huawei Kuwait Mobile Energy Storage Project

- What are the types of energy storage systems

- Join the 5G small base station China Communications centralized procurement

- Wholesale challenger breakers in Kuala-Lumpur

- 3 000 kW photovoltaic inverter

- Which platform has more outdoor communication battery cabinets in Banjul

- V DC to AC inverter

- New Energy Storage Household Outdoor Mobile Power Supply

- China circuit breaker outdoor in Chicago

- Is the energy storage cabinet suitable for home use

Commercial & Industrial Solar Storage Market Growth

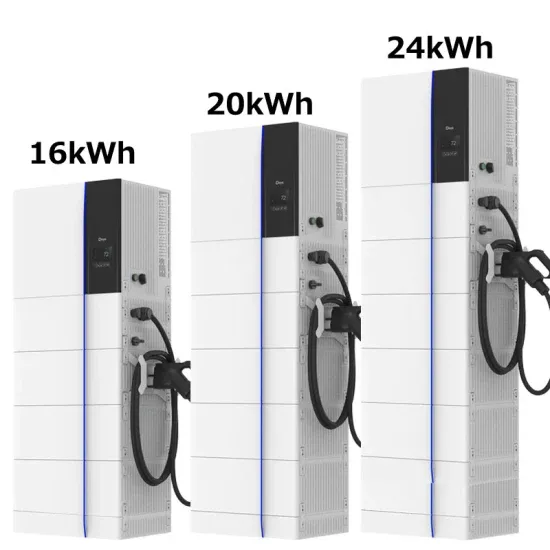

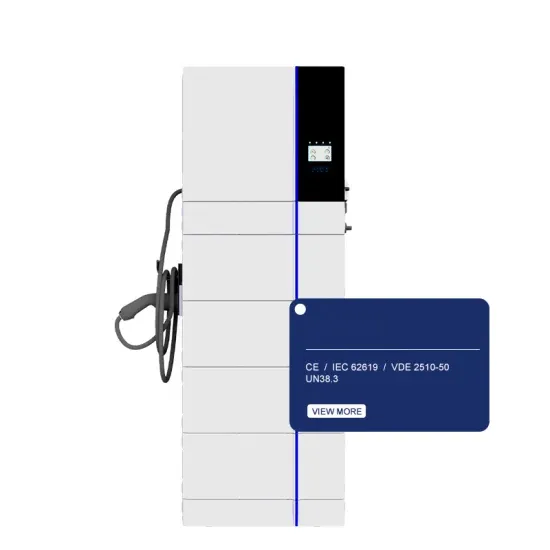

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.