A brief introduction to square lithium batteries.

Aug 7, 2025 · Domestic power lithium battery manufacturers often use square aluminum shell lithium batteries with higher energy density because the structure of square lithium batteries is

Comparison between cylindrical lithium batteries

Comparison between cylindrical lithium batteries and square lithium batteries. 1. Battery shape: Square size can be designed arbitrarily, while cylindrical

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Lithium Batteries: Cylindrical Versus Prismatic

Aug 6, 2019 · Cylindrical lithium batteries are widely used due to their lower production costs, automation-friendly design, and safety features that help

The difference between cylindrical lithium batteries and square lithium

Cylindrical lithium batteries are divided into three different systems: lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese mixture, and ternary materials.

Get to Know Square Battery: A Quick Guide

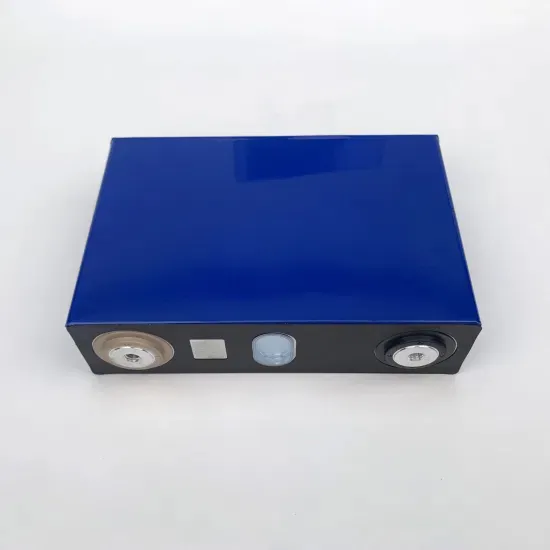

Nov 19, 2024 · Part 1. What is a square battery? Square batteries, also known as prismatic batteries, are energy storage devices shaped like a square or

3 Different Shapes Lithium Battery Structures

Nov 11, 2019 · At present, there are three main types of mainstream lithium battery structures, namely, cylindrical, rectangular and pouch cells. Different

Comparison between cylindrical lithium battery and square lithium

1. Battery shape: The square size can be designed arbitrarily, while the cylindrical battery cannot be compared. 2. Multiplication characteristics: the process limit for welding multipole lug of

Future of Lithium-Ion Batteries: Cylindrical,

Apr 18, 2025 · There are three primary forms of lithium-ion battery packaging: cylindrical, square, and soft pouch. Each packaging structure has distinct

Structural characteristics of 18650 cylindrical, square, and

Structural characteristics of 18650 cylindrical, square, and soft pack lithium batteries. With the further expansion of the electric vehicle market and the increasing demand for range, vehicle

Prismatic vs Pouch vs Cylindrical Lithium Ion

Jan 31, 2024 · In this article, we delve into the world of prismatic, pouch, and cylindrical lithium-ion battery cells, comparing their structures, advantages,

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · When choosing a lithium battery for your RV, marine vessel, or off-grid application, it''s critical to understand the three main cell formats. Each cell type brings unique advantages

Why batteries come in many different shapes

Apr 8, 2024 · The first batteries were made in the 1800s and have changed a lot since then. The reason batteries come in so many types has as much to do

Cylindrical, Pouch and Prismatic Battery Cell

Apr 18, 2025 · There are many cylindrical lithium-ion batteries models, such as 14650, 17490, 18650, 21700, 26500, etc. The cylindrical lithium-ion battery production process is mature,

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · What''s the difference between pouch, prismatic, and cylindrical cells in lithium batteries? Read our guide to find the right battery cell type for your system.

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · In terms of manufacturing process complexity, square lithium batteries have the most complex manufacturing process and relatively high costs due to their structural design

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

Cylindrical lithium ion battery – types,

Aug 4, 2023 · This article provides an overall introduction of cylindrical lithium ion battery, about its different types and different sizes, also the pros and cons.

The Three Major Li-ion Battery Form Factors:

Oct 14, 2020 · With lithium-ion batteries ever-rising in demand, it''s important to brush up on this battery''s three major form factors.

Comparison between cylindrical lithium batteries

PACK grouping: Cylindrical batteries have easier to use characteristics, so PACK technology is simple and has good heat dissipation effect; When packing

【Battery Products】Characteristics and

Dec 16, 2024 · 2.Square shell battery Square shell batteries are widely used in China. Their structure is relatively simple. Unlike cylindrical batteries, they use

Cylindrical, Pouch, and Prismatic Cell: Which will be more

Apr 19, 2025 · For instance, BaiC, Changan, Dongfeng, and other high-end domestic electric vehicles have adopted pouch power lithium-ion batteries. Statistics indicate that the output of

The advantages of cylinder battery vs square

Aug 17, 2025 · Tesla is using cylindrical cells in their electric vehicles over square cells because cylindrical cells prove more reliable from cylinder battery vs

Complete List of Cylindrical Lithium Battery Models.

Compared with soft pack and square lithium batteries, cylindrical lithium batteries have the longest development time, higher standardization, more mature technology, high yield rate, and low cost.

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jun 10, 2025 · In the new energy era, lithium batteries, as the core power and storage units, are of undeniable importance. Among the many characteristics of lithium batteries, the packaging

Cylindrical lithium battery, square lithium

Cylindrical lithium battery, square lithium battery, and pouch lithium battery, which is the future mainstream battery? Lithium batteries are divided into pouch

Square Batteries vs Cylindrical: Key Performance Differences

Three primary types of lithium-ion batteries, namely cylindrical, square, and soft-pack batteries, are at the forefront of the electric vehicle industry''s most promising developments. While

Cylindrical vs. Prismatic vs. Li-Po Battery: Key Differences

Feb 29, 2024 · At present, cylindrical batteries are mainly steel-cased cylindrical lithium iron phosphate. This cylindrical battery has high capacity, high output voltage, and good charge

Cylindrical Battery vs Prismatic Battery: Unveiling

Apr 18, 2025 · Contrary to cylindrical batteries, prismatic batteries feature a rectangular or square shape. They are assembled using stacked layers of

The difference between cylindrical battery,

Jun 12, 2023 · The difference between cylindrical battery, pouch lithium battery and square battery With the continuous development of the lithium battery

6 FAQs about [Cylindrical and square lithium batteries]

What is the difference between a square and a cylindrical battery?

Though both type of batteries use metallic casing for safety protection, the weight of the cylindrical cells is greater than that of square cells. As the name suggests square battery cells are prismatic or square-shaped lithium battery cells that have mostly steel or aluminum casings.

What is a cylindrical lithium-ion battery?

The cylindrical lithium-ion battery boasts mature production technology with high yields. Models like 14650, 17490, 18650, 21700, and 26500 are among the many cylindrical battery types available. This type's production process is mature, resulting in lower PACK costs, higher battery product yield, and consistent PACK quality.

What is a cylindrical battery?

At present, cylindrical batteries are mainly steel-cased cylindrical lithium iron phosphate. This cylindrical battery has high capacity, high output voltage, and good charge and discharge cycle performance. Lithium iron phosphate belts are promised to be used in solar lamps, lawn lamps, backup energy sources, power tools, toy models, etc.

What is a lithium polymer battery?

Lithium polymer batteries are currently the least used battery form in electric vehicles. But in fact, we are not unfamiliar with it. Most of the batteries in mobile phones are lithium polymer batteries. The biggest difference between lithium polymer, cylindrical, and prismatic batteries is that their outer casing is made of aluminum-plastic film.

What are the different types of lithium batteries?

The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination. Different packaging structures mean different characteristics, so what are their differences? Part 1. What’s the cylindrical lithium battery?

What are square battery cells?

As the name suggests square battery cells are prismatic or square-shaped lithium battery cells that have mostly steel or aluminum casings. The size, and shape of square batteries make them big capacity and less weight, and thus effectively suitable for tight spaces.

Industry Information

- Bridgetown Outdoor Energy Storage Power Station Project

- 240v circuit breaker for sale in Mongolia

- Portable power supply customization in Cordoba Argentina

- Price of photovoltaic small energy storage cabinet

- Ecuadorian power frequency inverter custom manufacturer

- Solar energy storage cabinet central energy storage system

- Charging piles store energy at night

- Huawei Myanmar Industrial Energy Storage Products

- The prospects of Ashgabat energy storage power plant

- Egypt Alexandria energy storage project successfully connected to the grid

- Electricity measurement of energy storage equipment

- Ranking of container manufacturers with solar energy

- Single-phase inverter dq

- Energy storage cabinet system introduction ESS power base station

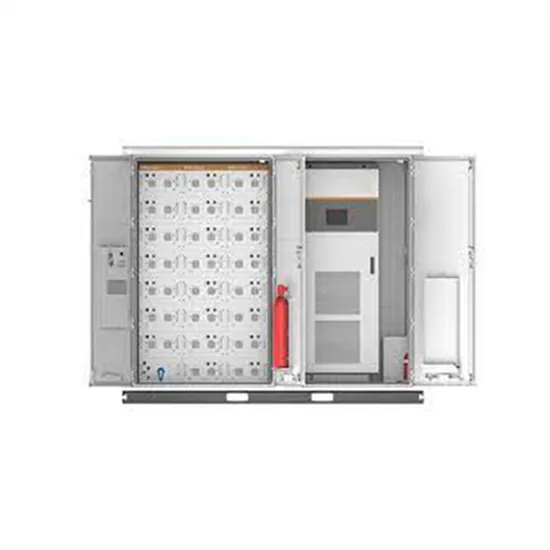

- Design of containerized energy storage system

- Wholesale 100ah power station in Russia

- How many watts can a 24v inverter use at most

- Recommendation of high power real standard inverter

- Aluminum alloy box production outdoor power supply

- Which outdoor power supply store in West Asia is good

- What are the suppliers of energy storage cabinets

- Energy storage 6kv ring network cabinet container

- Singapore Telecom PV site 418KWh

Commercial & Industrial Solar Storage Market Growth

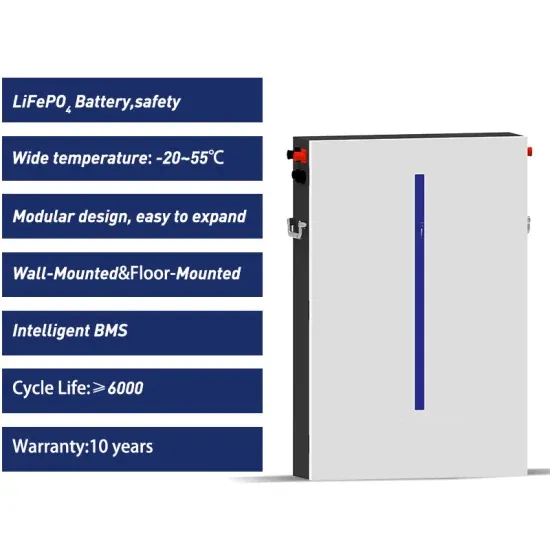

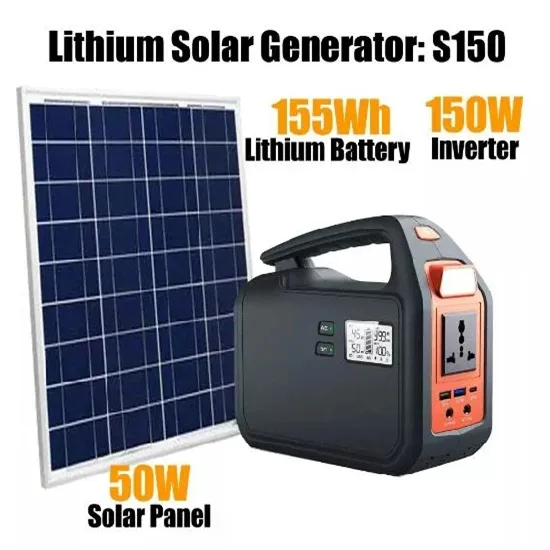

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.