Battery Management System Components | Ansys Courses

Key Takeaways - The pre-charge circuit in a BMS helps manage inrush current and prevent component failure. - The Management Control Unit (MCU) is the brain of the BMS, controlling

The Battery Management System: How It

Apr 30, 2025 · A battery management system can improve performance and extend battery life by making the charging and discharging cycles more

Working Principles and Core Functions of

May 20, 2025 · Battery Protection Circuit Modules (PCMs), also known as Battery Management Systems (BMS), are critical components in modern

Understanding Battery Management Systems

Nov 7, 2024 · Central to this energy management is the Battery Management System (BMS)—a technology that plays a crucial role in monitoring,

TI BATTERY MANAGEMENT SYSTEMS SEMINAR

Sep 29, 2023 · High-side switching with N-channel FETs High-side switching avoids ground disconnection during protection faults. Gate driver voltage requires voltage above the battery

Battery Management Systems: Powering Safer, Smarter

4 days ago · Chargers are pre-programmed with fixed voltage-current curves, matched to the battery''s type to ensure a safe charge from beginning to end. While effective, this approach

Battery Management System (BMS) for Efficiency and Safety

Jan 5, 2025 · In the age of renewable energy and electric vehicles (EVs), Battery Management System (BMS) plays a crucial role in ensuring the longevity, efficiency, and safety of batteries.

Battery Management System For Electric Vehicle:

Mar 24, 2025 · Basic Structure Of Battery Management System for Electric Vehicle BMS can be classified based on hardware and software components.

Active Discharge and Pre-charge of EV High Voltage

Apr 20, 2023 · Active Discharge & Pre-charge with ST''s latest THYRISTOR solutions Complete Product range including SCR, Microcontroller, Power device and Sense & Control Analog devices

Application of Power MOSFET in Battery

Jun 30, 2022 · All of these factors pose strict technical design challenges for the charge and discharge management of power MOSFET in the large-capacity

Why Pre-Charge Circuits are Necessary in High-Voltage

Dec 23, 2023 · A pre-charge circuit can be used to prevent stress and damage to the electric system by implementing a resistor and a switch to limit in-rush current. The TPSI3050-Q1 can

How does a BMS work

May 7, 2024 · Understanding how does a BMS works is essential for maximizing the performance and safety of battery systems. A Battery Management

Battery Management Systems (BMS): A

Mar 6, 2025 · Battery Management Systems (BMS) With the growing adoption of electric vehicles (EVs), renewable energy storage, and portable electronic

Battery Management Systems: Powering Safer, Smarter

4 days ago · Discover how the battery management system (BMS) plays a crucial role in ensuring safe and efficient charging for industrial machinery.

The Role of Battery Management Systems in EV Traction Battery

Dec 2, 2024 · A key enabler of optimal battery performance is the Battery Management System (BMS), a sophisticated system that monitors and manages the operation of the battery. In this

Li-Ion BMS

When initially connecting a battery to a load with capacitive input, there is an inrush of current as the load capacitance is charged up to the battery voltage. With large batteries (with a low

Pre Charging Control for EV – CMVTE

Apr 14, 2025 · ① In the first step of high-voltage energization, the battery management system (BMS) controls the negative contactor (K-) and the pre-charging contactor (Kp) to close and

Mi történik, ha a lítium akkumulátorokat

Jun 12, 2025 · Battery management systems (BMS) play a critical role in monitoring and maintaining the optimal temperature range for lithium batteries.

The Role of Precharge and Discharge Resistors in Safety

Apr 15, 2025 · Battery Management System (BMS) Integration The integration of precharge and discharge resistors with the EV battery management system (BMS) is essential for optimizing

Role of Pre-Charge Resistors in BMS

EV batteries need the right charging and discharging mechanisms, including the use of "pre-charge resistors", to guarantee their safety and longevity. A pre-charge resistor is a

Resistors for Battery Management Systems | TT Electronics

In automotive contexts, for example, the BMS is integrated into the controller area network (CAN bus) to regulate the input and output voltages between the battery pack and various power

Understanding the Role of a Battery Management

Mar 12, 2025 · What is a Battery Management System (BMS)? The battery management system is an electronic system that controls and protects a rechargeable battery to guarantee its best

Battery Management System Knowledge Paper on

Jan 22, 2024 · Report Insight The growing dependence on battery pack energy storage for electric vehicles, stationary energy storage and other applications has underscored the importance of

Lithium Batteries: BMS Theory

Feb 12, 2024 · In conclusion, understanding the pivotal role of a Battery Management System (BMS) in the performance, safety, and longevity of

High-Voltage Passive Precharge With Overcurrent

Sep 30, 2024 · Since this is for an 800V BMS, the blocking voltage must be higher. Note that EV batteries are often charged to a higher voltage than the system voltage; an 800V EV can hold

Charging strategies and battery ageing for electric

Jan 1, 2025 · This review article provides an overview of recent literature on how electric vehicle batteries are aged during different charging strategies, such as conductive charging, inductive

The role of Q33 and the connection of pre

Jul 17, 2024 · When the charger is a simple CC-CV source and does not know or pay attention to what the battery voltage, the battery may implement a pre

What is the role of AI in EV battery management

Mar 17, 2025 · Advancements in AI-driven battery management systems (BMS) are enhancing EV safety, optimizing charge cycles, and improving battery

What Does Battery Charging Mean on Toyota RAV4

Aug 7, 2025 · If your Toyota RAV4 displays a "battery charging" message, it means the vehicle is actively replenishing its hybrid or 12V battery. This is normal during driving or regenerative

A Guide to BMS MOSFET: Types, Key Role,

Mar 14, 2024 · Among them, BMS MOSFETs play a big role in the protection of lithium battery boards, and the main role of MOSFETs is to detect

Generating Power: Charging Speeds and the

Feb 10, 2022 · Jake Schmalz discusses the importance of a battery management system (BMS) in protecting lithium-ion batteries throughout the charging

Pre-Charge Circuits Lead to Safer EVs

Jan 5, 2024 · Pre-charging of electric-vehicle power circuits is one of the best ways to ensure component longevity and reliability while also establishing safer operations.

How does pre charging work on EVs – CMVTE

Jun 11, 2025 · ① The battery management system BMS controls the closing of the negative contactor (K-) and the pre-charging contactor (Kp) to pre-charge the bus capacitor C in the

Battery Management System Components | Ansys Courses

This lesson covers the various components of a Battery Management System (BMS) and their functions. It delves into the different types of circuits in a BMS, such as the pre-charge circuit,

What is the role of a pre-charge circuit in BMS?

1. Purpose of Pre-Charge Circuit: - A pre-charge circuit serves as an essential safety feature during the initial connection of a battery to a load. - Its primary role is to limit the inrush current

6 FAQs about [The role of battery BMS pre-charging]

What is a pre-charge circuit in a BMS?

The pre-charge circuit in a BMS helps manage inrush current and prevent component failure. - The Management Control Unit (MCU) is the brain of the BMS, controlling all other subsystems and determining the state of the battery pack. - Cell balancing is crucial for maximizing energy usage and extending cell life.

What is a battery management system (BMS)?

This lesson covers the various components of a Battery Management System (BMS) and their functions. It delves into the different types of circuits in a BMS, such as the pre-charge circuit, which helps manage inrush current and prevent component failure.

What is a EV battery management system (BMS)?

The integration of precharge and discharge resistors with the EV battery management system (BMS) is essential for optimizing vehicle performance. A BMS typically maintains discharge rates between 0.2 and 0.5C to balance performance, battery longevity, and safety.

What are the different charging modes in a BMS?

Adaptive Charging Modes: The BMS can employ various charging methods such as Constant Current (CC), Constant Voltage (CV), and Multi-Stage Constant Current (MCC), depending on the battery type and usage patterns. These modes help in efficiently managing the charging process to extend battery life.

How does a battery management system work?

Short Circuit and Overcurrent Protection: The BMS detects and responds to short circuits and overcurrent situations by disconnecting the battery. This immediate action is vital to prevent potential damage or hazards. State of Charge (SOC) Balancing: The BMS optimizes the battery’s performance by balancing the state of charge across all cells.

Why do EVs need a battery management system?

Moreover, the integration of advanced battery management systems (BMS) in EVs allows for better control of charging and discharging processes, maintaining optimal discharge rates between 0.2 and 0.5C to ensure an ideal balance between performance, battery longevity, and safety.

Industry Information

- Should photovoltaic power generation be connected to the grid first or should it be stored first

- Price of fully automatic production equipment for photovoltaic panels

- Modify solar water sprinkler pump

- How to match solar panels with inverters

- 6MW photovoltaic energy storage power station design

- Eritrea Air Energy Storage Battery

- Outdoor power supply 20w

- Prospects for energy storage power station operation and maintenance

- 425 Specifications Photovoltaic Panel

- Battery quantity near the communication base station flow battery

- Solar Photovoltaic Panelsiv

- New photovoltaic panel wholesale manufacturers

- Lithium battery pack is not balanced

- Brazzaville EK small portable energy storage enterprise

- Does the lithium battery BMS need to be turned on

- Slovenia BESS Photovoltaic Energy Storage BESS

- Outdoor power supply with high safety factor

- Harare wall mounted energy storage battery factory

- Hbd outdoor power supply

- Nicaragua energy storage battery cabinet seller

- Mobile 5g base station is not powered

- Marshall Islands three-phase inverter

- Pros and cons of wind power for communication base stations

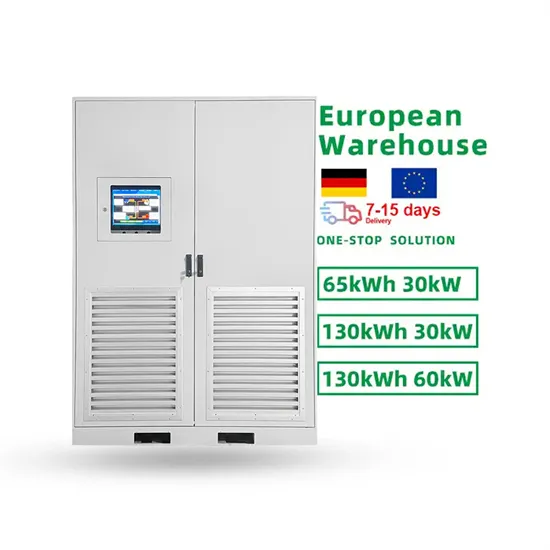

Commercial & Industrial Solar Storage Market Growth

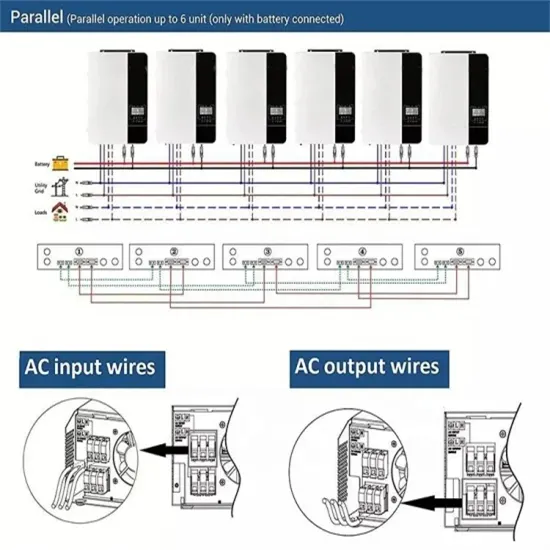

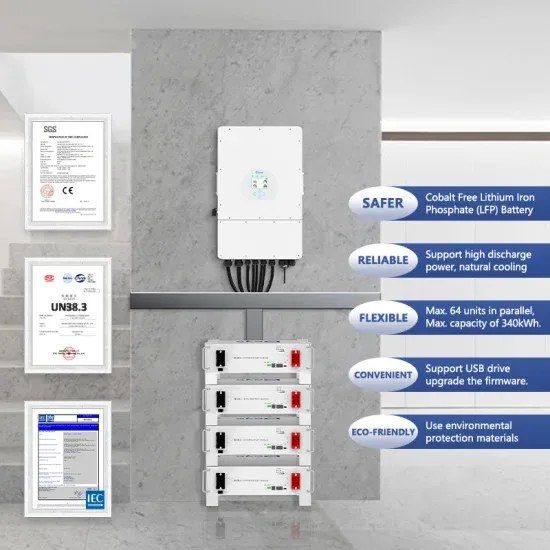

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

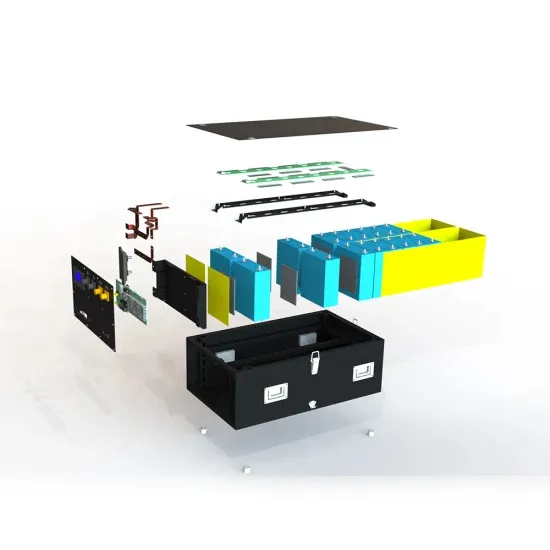

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.