Towards an improved scope for flow battery testing in North

Herein, the current landscape of redox flow batteries (RFB) safety is reviewed through: A case study of commercial FBES safety tests An evaluation of the relevance and inadequacies of the

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · The vanadium redox flow battery (VRFB), regarded as one of the most promising large-scale energy storage systems, exhibits substantial potential in th

A review of vanadium electrolytes for vanadium redox flow batteries

Mar 1, 2017 · There is increasing interest in vanadium redox flow batteries (VRFBs) for large scale-energy storage systems. Vanadium electrolytes which function as both the electrolyte

Overcoming thermal issues of vanadium redox

Feb 3, 2023 · Chinese scientists have analyzed reports of thermal issues with vanadium redox flow batteries (VRFB) and existing thermal management

(PDF) Environmental and Health Impacts of

Nov 29, 2023 · Abstract Due to its distinct design and operation, the vanadium redox flow battery (VRFB) is a cutting-edge energy storage technology that

Vanadium Redox Flowbattery

Aug 8, 2025 · What is vanadium? Vanadium is the 23rd element in the periodic table and is mainly used as a strong alloy in the tool industry. Furthermore, it is a metal with a high electrical

FLOW BATTERIES

Apr 28, 2023 · Sustainability Story A flow battery is a short- and long-duration energy storage solution with sustainability advantages over other technologies. These include long durability

Critical safety features of the vanadium redox flow battery

May 31, 2017 · In this work the behaviour of the vanadium redox flow battery is examined under a variety of short-circuit conditions (e.g. with and without the pumps stopping as a result of the

Safety Considerations of the Vanadium Flow Battery

Jan 6, 2023 · As the global installed energy capacity of vanadium flow battery systems increases, it becomes increasingly important to have tailored standards offering specific safety advice.

Dangers of vanadium flow batteries

In the toxicological study of vanadium redox flow batteries, the chemical properties of vanadium and its forms in the battery, especially its different oxidation states (V(II), V(III),...

FPEeXTRAIssue26

Energy Storage System Safety: Comparing Vanadium Redox Flow and Lithium-Ion–Based Systems By Matthew Paiss The field of large-format stationary energy storage systems (ESS)

Membrane-free redox flow battery: From the

Jan 22, 2025 · The membrane-free redox flow battery, using immiscible electrolytes, shows promise for various applications similar to conventional

(PDF) Environmental and Health Impacts of

Nov 29, 2023 · Of the flow battery technologies that have been investigated, the all-vanadium redox flow battery has received the most attention and has

Vanadium Flow Battery (VFB) | Vanitec

Large scale deployments of vanadium redox flow batteries are underway across the globe, with many others being planned or under construction. Ensuring a strong supply of quality

Flow battery

A flow battery, or redox flow battery (after reduction–oxidation), is a type of rechargeable battery where rechargeability is provided by two chemical components dissolved in liquids contained

Advanced Electrolyte Formula for Robust

Jan 24, 2024 · A novel approach to designing electrolyte additive significantly increases the overall performance and of the all-vanadium redox flow battery.

Vanadium Redox Flow Battery Field Testing Results

Nov 9, 2022 · The Electric Power Research Institute, Southern Research, and Los Angeles Department of Water and Power have collaborated on field testing of vanadium flow batteries.

The Vanadium Redox Flow Battery

Jul 27, 2025 · Taking into account the main benefits of RFB systems used as electrochemical ESS, many explorations were carried out in order to improve their operation, design and

Vanadium electrolyte: the ''fuel'' for long-duration

May 22, 2023 · Samantha McGahan of Australian Vanadium on the electrolyte, which is the single most important material for making vanadium flow batteries.

Chemical Hazard Assessment of Vanadium Vanadium

For all-vanadium redox flow batteries, the spilled electrolytes are highly acidic and strongly oxidative and can corrode battery housings, structural components, and nearby equipment.

Flow Batteries: Recent Advancement and Challenges

Sep 3, 2022 · This chapter presents a redox flow batteries review that has been investigated and developed over the past few decades. Redox flow batteries (RFBs) can be used as stationary

Redox Flow Batteries: potential, alternatives and

May 14, 2024 · The redox flow battery market, although less well known than conventional lithium or solid-state batteries, is gaining momentum as a robust

Dangers of vanadium flow batteries

Vanadium Redox Flow Battery. The flow battery is composed of two tanks of electrolyte solutions, one for the cathode and the other for the anode. Electrolytes are passed by a membrane and

Vanadium redox flow batteries: A comprehensive review

Oct 1, 2019 · Interest in the advancement of energy storage methods have risen as energy production trends toward renewable energy sources. Vanadium redox flow batteries (VRFB)

Chemical Hazard Assessment of Vanadium–Vanadium Flow Battery

Jun 11, 2025 · For example, sulfuric acid in lead-acid batteries is highly corrosive, and a rupture in the battery casing can lead to corrosive chemical leaks. (17) In lithium-ion batteries, thermal or

Towards an improved scope for flow battery testing in North

Based on Figure 1-1, UL 1973 addresses three main failure modes: leakage of tubings, failure of valves and failure of pumps. However, the standard does not address corrosion of electrodes

FLOW BATTERIES

Feb 24, 2025 · Since the lithium-ion batteries frequently used for this purpose suffer from a number of disadvan-tages – among other things their poor ability to store energy over

What are the main safety concerns specific to

Nov 12, 2024 · Overall, while vanadium flow batteries are safer than lithium-ion batteries regarding fire risks, their corrosive electrolyte and potential for leaks

Showdown: Vanadium Redox Flow Battery Vs

4 days ago · Explore the battle between Vanadium Redox Flow and lithium-ion batteries, uncovering their advantages, applications, and impact on the future

The rise of vanadium redox flow batteries: A game-changer

6 days ago · This article explores the role of vanadium redox flow batteries (VRFBs) in energy storage technology. The increasing demand for electricity necessitat

Vanadium redox flow batteries can provide

Feb 2, 2023 · The iron-chromium redox flow battery contained no corrosive elements and was designed to be easily scalable, so it could store huge

Vanadium Redox Flow Batteries

Jul 30, 2023 · Flow batteries are durable and have a long lifespan, low operating costs, safe operation, and a low environmental impact in manufacturing and recycling. The technology

Chemical Hazard Assessment of Vanadium Vanadium

The largest scale vanadium−vanadium flow batteries have been reported in China, with a 100 MW/400 MWh system reportedly commissioned in 2022 and a 175 MW/700 MWh battery

Self-Discharging and Corrosion Problems in

Jan 24, 2023 · Abstract and Figures Vanadium redox flow battery (VRFB) has a potential for large energy storage system due to its independence of energy

Despite technological advances, flow batteries struggle against

Mar 14, 2017 · The market leader in flow battery chemistry is vanadium, but researchers are working on other chemistries to bring down costs and improve the safety and environmental

6 FAQs about [Are vanadium flow batteries corrosive ]

How important is safety advice for a vanadium flow battery?

As the global installed energy capacity of vanadium flow battery systems increases, it becomes increasingly important to have tailored standards offering specific safety advice.

Will flow battery suppliers compete with metal alloy production to secure vanadium supply?

Traditionally, much of the global vanadium supply has been used to strengthen metal alloys such as steel. Because this vanadium application is still the leading driver for its production, it’s possible that flow battery suppliers will also have to compete with metal alloy production to secure vanadium supply.

Why are vanadium batteries so expensive?

Vanadium makes up a significantly higher percentage of the overall system cost compared with any single metal in other battery technologies and in addition to large fluctuations in price historically, its supply chain is less developed and can be more constrained than that of materials used in other battery technologies.

What is a vanadium redox flow battery (VRFB)?

The vanadium redox flow battery (VRFB) has gone from being a laboratory curiosity , to gaining significant commercial application over the last decades . To date over a hundred systems have been installed worldwide, for stationary energy supply. Redox flow batteries store energy chemically in positive and negative electrolytes.

How can vanadium redox flow batteries increase their share in energy storage?

Overcoming the barriers related to high capital costs, new supply chains, and limited deployments will allow VRFBs to increase their share in the energy storage market. Guidehouse Insights has prepared this white paper, commissioned by Vanitec, to provide an overview of vanadium redox flow batteries (VRFBs) and their market drivers and barriers.

Why is a flow battery better than other battery types?

The high heat capacity of the aqueous electrolyte is also beneficial in limiting the temperature rise. It will be seen that the flow battery is therefore considerably safer than other battery types, in this respect.

Industry Information

- Abkhazia Energy Storage Battery Dealer

- Flexible solar panels photovoltaic polycrystalline

- Best factory price 3 mppt inverter producer

- Which Middle East power storage vehicle is the best

- Lithium iron phosphate battery pack 48V capacity 50ah

- Industrial and commercial energy storage battery voltage

- What is the best battery for photovoltaic panels

- Hot sale small solar inverter in China producer

- 12 volt 45a inverter

- Tunisia container custom wholesale

- Communication 5g maintenance base station

- Power breaker switch for sale in New-Zealand

- Iran s solar energy storage

- Dual output voltage inverter

- Photovoltaic single-glass bifacial modules

- Flow battery failure modes

- Bolivia energy storage lithium battery supplier

- Huawei Latvia Power Storage

- Mogadishu Industrial Uninterruptible Power Supply BESS

- 100ah power station for sale in Poland

- Nicosia Home Energy Storage System

- What are the large energy storage systems

- Huawei Communication Base Station Power Supply

Commercial & Industrial Solar Storage Market Growth

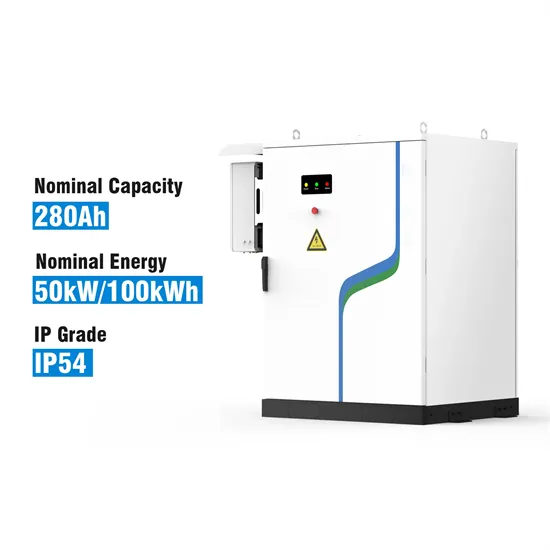

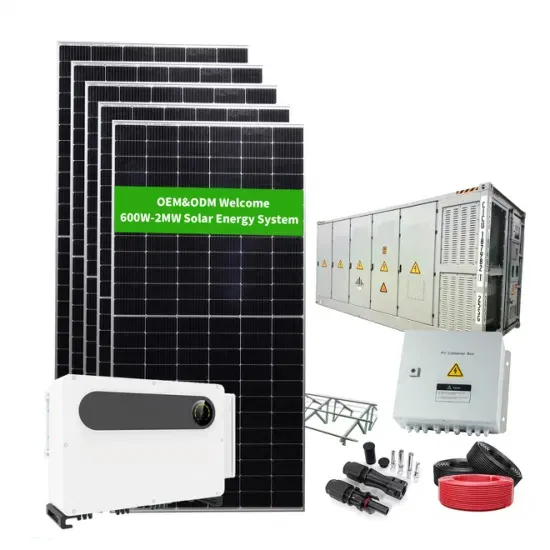

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.