Solar Panel Lamination: procedure, advantages

Solar panel lamination is crucial to ensure the longevity of the solar cells of a module. As solar panels are exposed and subject to various climatic impact

transparent solar panels semi transparent solar

Photovoltaic windows, solar cells are connected together and then laminated under toughened, high transmittance glass to produce reliable, weather

Investigation of static and dynamic mechanical loads on light-weight PV

Nov 15, 2024 · The findings indicate that a low inclination installation is preferable, and a glass-glass PV module with a 2.5 mm glass thickness can withstand static and dynamic mechanical

A layer-wise theory for laminated glass and photovoltaic panels

Jun 1, 2014 · Laminated plates with glass skin layers and a core layer from Polyvinyl Butyral (PVB) are widely used in the civil engineering and automotive industry [1], [2], [3]. Crystalline

PhotoVoltaic Lamination Process | Luc Moeyersons

Nov 30, 2022 · This text provides an overview of the PhotoVoltaic lamination process. It examines the differences between various types of laminators, and outlines the process flow for each. It

Onyx Solar, Building Integrated Photovoltaics

2 days ago · Onyx Solar: Leader in Building Integrated PV Solutions. Custom Photovoltaic Glass for energy generation that enhances energy efficiency and

Gain Solar: Comprehensive BIPV Solutions For

Mar 31, 2025 · Unlike conventional double-glass PV modules, both types of BIPV products use PVB instead of EVA as the encapsulant for the cell matrix,

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Customized

The glass forms the front end of photovoltaic module and protects components housed within the laminate from the weather and mechanical stresses. At the

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Lamination Key to Module Reliability

Oct 29, 2010 · Photovoltaic (PV) modules need to withstand the rigors of outdoor exposure in all kinds of climates for long periods – 25 years or more – to convert sunlight to electricity at a

Photovoltaic solar panel double glass lamination tooling

Photovoltaic solar panel double glass lamination tooling What is the lamination process in a photovoltaic (PV) module? The lamination process is one of the most critical steps that

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · These photovoltaic modules use high-efficiency monocrystalline silicon cells (the cells are made of a single crystal of very high-purity silicon) to

Satinal

Mar 19, 2025 · Here is a deep dive into solar panel technology and the latest industry trends from Satinal, an Italian company that produced interlayers for laminated safety glass. In 2020, they

A user-defined finite element for laminated glass panels

Laminated glass and photovoltaic modules can also be analyzed using the three-dimensional theory of elasticity and applying solid finite elements for the numerical solution.

Unsymmetric three-layer laminate with soft core for photovoltaic modules

Nov 1, 2013 · One possibility is the use of solar radiation in photovoltaic modules and thermal solar modules for electricity generation. Various designs of photovoltaic modules were

Lamination process and encapsulation materials for

May 21, 2024 · Lamination process and encapsulation materials for glass–glass PV module design Gianluca Cattaneo1, Antonin Faes1, Heng-Yu Li1,2, Federico Galliano1,2, Maria

Glass-Glass PV Modules

4 days ago · Glass-Glass module designs are an old technology that utilises a glass layer on the back of modules in place of traditional polymer backsheets.

Solar Panels Manufacturer Technical

Feb 22, 2023 · Explore the critical process of PV Module Lamination in this detailed technical explanation. Discover how lamination enhances the

Analysis of laminated glass beams for photovoltaic

Mar 16, 2021 · Laminated glass beams and plates are widely used in glazing and photovoltaic applications. One feature of these structures is a relatively thin and compliant polymeric layer

Influence of Lamination Conditions of EVA

Oct 29, 2023 · Encapsulation is a well-known impact factor on the durability of Photovoltaics (PV) modules. Currently there is a lack of understanding on the

Solar Panel Lamination: procedure, advantages

Oct 7, 2011 · How is a solar panel laminated? PV lamination is a proven concept and works as follows: In order to laminate a solar panel, two layers of ethylene

Satinal explains: the science behind solar PV modules

Feb 10, 2025 · Satinal, a leading Italian Company focused on the production of STRATO® Interlayers for safety glass lamination, has introduced STRATO® SOLAR PV Encapsulants for

Development and testing of light-weight PV modules based on glass

May 26, 2022 · In this work we elaborate on the potential of glass reinforcement for PV modules, replacing the glass to reduce their weight. In 2 encapsulation approaches, either reinforcing

How a PV Module Laminator Enhances Solar

Mar 30, 2024 · One big challenge is laminating the solar cells, which makes them strong against temperature changes and helps them work better. This article

Monocrystalline Laminated Glass Solar PV

High quality Monocrystalline Laminated Glass Solar PV Module RXJJ-105 from China, China''s leading Monocrystalline Solar PV Module product, with strict

Technical properties of Onyx Solar Photovoltaic

3 days ago · The multifunctional properties of photovoltaic glass surpass those of conventional glass. Onyx Solar photovoltaic glass can be customized to

Solar Glass & Mirrors, Photovoltaics | Solar Energy

The Solar Glass Challenge The objectives for solar glass are: Ultra-bright glass needed with high solar transmission to ensure high efficiencies in the overall pv module. Mechanical strength to

Solar Glass

1 day ago · Let the light in with Mitrex Solar Glass — a powerhouse in disguise, where photovoltaics meet limitless design, where color meets clarity. You''re

PV module laminators

The fastest two-stage lamination process for glass-glass modules and glass backsheet modules is based on a vacuum membrane press in the first step and concludes lamination with a flat

6 FAQs about [Laminated glass photovoltaic modules]

What is the lamination process in a photovoltaic (PV) module?

The lamination process is one of the most critical steps that influences the quality of a photovoltaic (PV) module in terms of long term stability .

How is a solar panel laminated?

PV lamination is a proven concept and works as follows: In order to laminate a solar panel, two layers of ethylene-vinyl acetate (EVA) are used in the following sequence: glass / EVA / solar cell strings / EVA / tedlar polyester tedlar (TPT). Ready for lamination.

How are PV modules laminated?

The lamination of PV modules is most frequently carried out using a vacuum-membrane laminator with a single heating plate (Fig. 5) and a typical process based on three main steps .

What is solar module lamination?

Solar module lamination is a procedure that involves the placement of solar cells between layers of material with the intention of not only providing protection but also weather resistance to the module. However, this is of utmost importance because it protect the components from the environment, like moisture, dust, and contact stress.

Is photovoltaic lamination a non-autoclave lamination process?

One could catalogue the PhotoVoltaic lamination process also under “non-autoclave lamination process”. But because of the size of the industry (and of the popular request), I decided to treat it as a separate item. I will not dwell on the different PV technologies but remain in the domain of lamination. Stage 0: Loading of the laminate.

What is the fastest two-stage lamination process for glass-glass modules?

The fastest two-stage lamination process for glass-glass modules and glass backsheet modules is based on a vacuum membrane press in the first step and concludes lamination with a flat press heated on both sides. Compared to the SL process, throughput times are considerably reduced, which in turn significantly increases capacity.

Industry Information

- Energy storage affects equipment

- Prices of photovoltaic glass and ordinary glass

- Montevideo lithium battery energy storage cabinet installation

- What is a pure sine wave inverter

- String-type grid-connected energy storage power station

- Maximum power output of energy storage battery

- 5kw inverter backstage

- Battery Energy Storage Solution Design in North America

- Budapest solar cell energy storage

- Solar lights household spotlights

- How long does it take to repair the new energy battery cabinet

- 48v13 series lithium battery pack

- Abuja Power Outdoor Portable

- New high-power inverter in Busan South Korea

- Dakar Advantage Energy Storage System

- Photovoltaic energy storage linkage

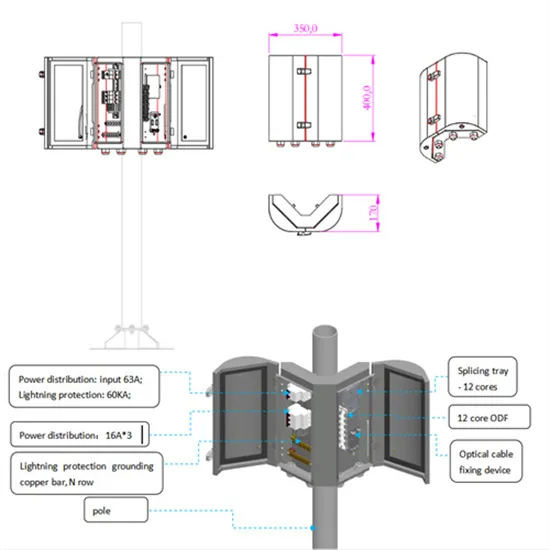

- Communication base station battery energy storage system migration project

- Asmara energy storage lead-acid battery direct sales

- Algiers grid-side energy storage cabinet manufacturer

- Micro inverter No 1 in the world

- Cheap factory price thermal breaker Factory

- Small photovoltaic power generation energy storage solution

- Battery cabinet 64 pieces

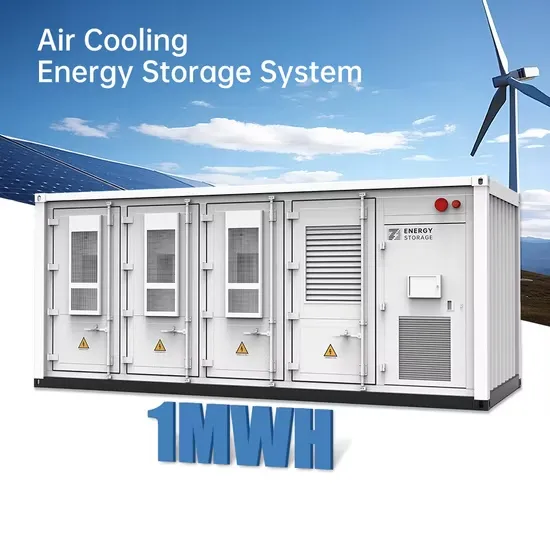

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.