Battery Inspection Checklist

Oct 10, 2024 · This detailed Battery Inspection Checklist ensures battery performance and safety. This checklist, which includes both visual and

Manufacturing supervision and inspection of lithium battery energy

Dec 15, 2024 · Under the background of "carbon peak" and "carbon neutrality", large-scale energy storage equipment is an important basic equipment to support the new power sys

Battery Cabinet Inspection Checklist | HuiJue Group E-Site

As modular battery architectures dominate new installations, perhaps we''ll see inspection intervals tighten from months to minutes. The real question remains: How soon will your team

Battery Energy Storage System Inspection and Testing

Mar 13, 2023 · SEC will inspect and commission these systems according to its internal checklist, focusing only on the components and equipment impacting the distribution network and the

Energy Storage Product Inspection Standards: What You

Jul 25, 2021 · But what happens when these systems fail? Energy storage product inspection standards act as the ultimate quality control checklist, preventing your clean energy dreams

New energy battery cabinet inspection and maintenance

Overview of EV battery testing and evaluation of EES systems To ensure safe battery use and reduce average lifecycle costs, EV battery inspection methods with real-time implementation

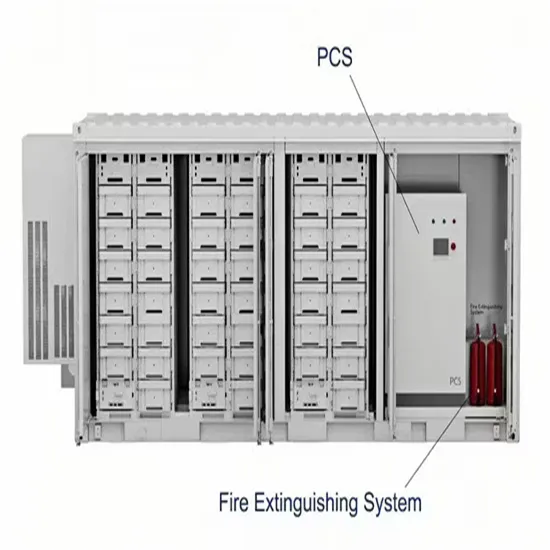

Energy Storage Cabinets: Key Components,

Aug 12, 2024 · Energy storage cabinets are crucial in modern energy systems, offering versatile solutions for energy management, backup power, and

New energy battery cabinet inspection and maintenance

A properly implemented maintenance program will aid in prolonging battery life,prevent avoidable battery failures,reduce premature battery replacement,ensure that the battery systems is

Performing a Visual Inspection of the Battery

Jun 13, 2025 · Check that all electrical safety devices (e.g., AC miniature circuit breaker, circuit breaker in the DC distributor, and external switches in the battery cabinet doors) are intact. If

New Energy Battery Cabinet Inspection

White Paper | Battery Inspection, Maintenance, and Testing Inspect and verify the structural integrity of the battery rack or cabinet. Scope of Work – VRLA Battery Inspections Monthly

New energy battery cabinet inspection and maintenance

How often should a battery be inspected? Measure the electrolyte temperature of 10% or more of the battery cells. At least once per year,the quarterly inspection will be augmented as follows:

Energy storage cabinet delivery inspection standards

Energy Storage Cabinets Explore our field and warranty services in addition to our engineered structures to find an energy storage cabinet for your renewable energy storage needs.

Energy Storage Battery Inspection: What You Need to Know

But when your solar-powered concert stage goes dark mid-performance, suddenly battery inspection becomes headline news. From utility companies to EV charging stations, energy

New Energy Battery Cabinet Inspection Method

How do non-destructive inspection methods affect lithium-ion batteries? In this framework,non-destructive inspection methods play a fundamental role in assessing the condition of lithium

Energy Storage Cabinet Inspection: A Critical Maintenance

You know that feeling when your phone battery suddenly drops from 30% to 5%? Now imagine that happening to a 500kWh energy storage cabinet. Over 68% of battery failures in

Energy storage cabinet inspection process

Battery cabinet fire propagation prevention design: If an energy storage system is not compartmentalized, a thermal runaway event in a single battery is extremely likely to spread to

New energy battery cabinet inspection and maintenance

Why do you need a battery maintenance program? A properly implemented maintenance program will aid in prolonging battery life,prevent avoidable battery failures,reduce premature battery

How to Do the Routine Site Inspection of Energy Storage

Senmarck Energy Battery energy storage stations used in big #infrastructure projects are typically rented for about 1 to 2 years, and regular on-site inspections are essential for Senmarck after

6 FAQs about [Separate inspection of new energy battery cabinet]

How does SEC inspect and commission a distribution network?

SEC will inspect and commission these systems according to its internal checklist, focusing only on the components and equipment impacting the distribution network and the connection point. Referring to the approved WERA regulations and SEC connection process, the inspection and testing are executed in Step 3 named as “REG Connection” phase.

Do you need a representative to test a battery?

Battery manufacturers may require that a representative be present to witness or conduct commissioning. The test should be conducted under environmental conditions included in the design specifications and deemed to be appropriate by the battery manufacturer. The Project shall comply with WERA’s Regulatory Framework and SEC’s Distribution Code.

What should be included in a battery test?

This should include at least: Verification of interconnected battery rack or string functionality. Auxiliary equipment testing, including standard operational lighting, emergency lighting, and HVAC or other thermal management system functionality.

How do I perform a battery test?

If required by the battery manufacturer, supplier shall conduct the test with the presence of the manufacturer representative. Turn on datalogging, record all parameters at 1/4 second intervals or faster as required by contractual requirements, and confirm data is being saved in an appropriate location.

Does SEC have a right to witness a Reg energization & operation?

During REG Energization & Operation phase, SEC will have the right to witness the commissioning tests only if deemed necessary. SEC eventually will be responsible for issuing the “Final Operation Notification” and If deemed necessary, SEC is entitled to ask the Eligible Consumer to sign a REG System Operational Agreement.

What is electrical inspection?

Inspection – examination of an electrical installation using all the senses in order to ascertain correct selection and proper erection of electrical equipment.

Industry Information

- Malta photovoltaic folding container house wholesale

- Oman Industrial Energy Storage Cabinet Cost

- Asia Communications 5G Base Station Subsidy

- Which battery cabinet is good durable and cheap

- San Jose Solar Street Lights

- Mobile energy storage battery vehicle manufacturer

- How many degrees can the outdoor power supply have

- Solar power station 4 MW

- Small solar inverter for sale in Jordan

- Home Energy Storage Recommendations

- Thailand Communications 5G Base Station Project

- How many volts is the inverter voltage in Dakar

- Eritrea energy storage power generation project completed

- Vertical battery cabinet series

- St Johns Solar Energy Storage Project

- Single phase circuit breaker in Vietnam

- Cheap China 1 5 kva hybrid inverter company

- Jerusalem pure sine wave inverter manufacturer

- Berlin Large Corrugated Container Wholesale

- Cooling system design of battery cabinet

- Household solar booster pump

- Lomé Solar Photovoltaic Panel Purchase Cost

- Which is the best high frequency inverter in Jordan

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.