Underground Mine Communication Systems

Underground Mining, Tunneling & Water Industrial Communications Products We understand that mining, steel, tunneling, water and construction operations

On Underground Mine Communication Systems

Jan 4, 2025 · The majority of underground coal mines (UCMs) rely on wired-based communication system for communication as well as data transmission.

Millimeter-Wave Massive MU-MIMO

Jan 1, 2023 · The millimeter-wave (mmWave) and massive multiple-input multiple-output (MIMO) wireless communication technologies provide vital

Mining Communication Base Station

High power & long-range mining communication base stations designed for your needs, call us to discuss mining base station requirements.

Mining_Brochure_Final(3)

Jul 9, 2012 · Wireless Communication Enables the "Digital" Open-pit Mine A profitable open-pit mining operation depends on effective communication, efficiency and safety. A high-capacity

Wireless Communication Systems For Underground

Aug 9, 2019 · In the Val d''Or mine, Canada, experiments gave fruitful results regarding mesh wireless local area network (WLAN) using WAP (Wireless Access Point) protocol [28].

Coal mine 5G wireless communication system construction

The basic architecture of 5G wireless communication system in coal mine is proposed: 5G core network, base band unit (BBU), remote radio unit hub (RHUB) and 5G base station are

Millimeter-Wave Massive MU-MIMO Performance

Apr 12, 2024 · Abstract—In this article, a performance analysis of millimeter wave (mmWave) massive multiuser multiple-input and multiple-output (MU-MIMO) channel within an

Rate Optimization of Intelligent Reflecting

Oct 20, 2024 · This paper proposes a three-step joint rate optimization method for intelligent reflecting surface (IRS)-assisted coal mine wireless communication

The Application of WiFi 6 Technology in

Mar 1, 2021 · The WiFi 6 signal coverage scheme solves the problem of wireless network signal coverage in long-distance roadway underground coal mine by

CDC

Dec 2, 2019 · Section 2 of the OMSHR advanced tutorial on wireless communication and electronic tracking covering communication system

Mining Communications Solutions | Wireless

Get in touch with us now, we don''t turn jobs down. Mining Comms Solutions is a WA-based Communications company providing services across Australia. Our

Private wireless communications for underground mines

Sep 30, 2022 · Underground mining operators have expressed the need for wireless connectivity to support a wide variety of use cases, including simple and basic connectivity for personnel,

Wireless Connectivity Enables Effective Communication in Open-pit Mines

Wireless Communication Enables the "Digital" Open-pit Mine A profitable open-pit mining operation depends on effective communication, efficiency and safety. A highcapacity wireless

Modeling and measurements for wireless communication networks

Jan 1, 2020 · This is driven by the fact of limited availability of real-time data of operational underground mines with different measurement considerations. This paper reports extensive

Research and development of 5G communication system

Sep 4, 2023 · When the uplink rate is 30 Mbit/s, the wireless coverage radius (unobstructed) of the base station in the open-pit coal mine is ≥ 400 m. ② The wired transmission distance from

Mining and mission-critical wireless connectivity

Apr 30, 2025 · These transformative digital applications all require business-critical network connectivity and, given the nature of mining operations, wireless mobile communications are

Underground Mining Wireless Communications

Two-way-radio systems are widely used in underground mines for voice communications. All analogue and digitally modulated two-way radios,

5G Empowers Intelligent Mining for High-quality

Jun 8, 2022 · The wireless adopts the MOCN solution to achieve seamless connection between the public network and the private network: When the 5G

Wireless communication technology evolution in underground coal mines

Mine communication is an indispensable part of the intelligent development of coal mines. This paper analyzes the advantages and disadvantages of different communication systems and

Wireless Communication in Underground Mining

Apr 21, 2025 · This paper systematically reviews the literature on wireless communication challenges for underground mining teleoperation, identifying open research problems,

Research and development of 5G communication system

In order to meet the needs of remote monitoring, video monitoring, data acquisition, and voice communication in coal mines, the 5G communication system used in coal mines should have

Wireless networks in underground mines

Jan 1, 2016 · A case study on underground mine communications in Kemi mine, Finland is also presented. The focus of the case study is to expand the network coverage with a portable

Analysis of wireless transmission tests in mines and preferred

The development and deployment of mobile communication systems, personnel and vehicle positioning systems in mines require an analysis of wireless transmission characteristics, the

Surface Electromagnetic Wave-Based Wireless Communication System for Mines

Apr 1, 2021 · The results obtained prove the fundamental possibility of designing multichannel induction communication systems with a guaranteed communication range of over 4 km from

Becker Wholesale Mine Supply

Dec 2, 2024 · Enhance safety and efficiency in mining with Becker''s advanced Radio Communication Systems. Reliable solutions tailored for underground

Mine Rescue System, Wireless Communication

Aug 18, 2025 · The Mine Rescue Operations Wireless Communication System ensures communication in the mining excavation during activities related to

Design and implementation of metasurfaces for enhancing

Apr 1, 2025 · Coal mine tunnels contain numerous bends and branches that obstruct the direct propagation of wireless signals between transmitters and receivers, creating non-line of sight

5G Empowers Caojiatan Smart Coal Mine

Jul 25, 2022 · 5G Empowers Caojiatan Smart Coal MineMoreover, the 5G iCube cloud-network solution used by Caojiatan Coal Mine has been upgraded from

Mine Communication Technique | SpringerLink

Jan 1, 2009 · TTA — It includes wireless communication systems. Table 1.1 summarizes the frequency spectrum designations with their wavelength

VWHPIRU0LQHV

Jan 9, 2024 · Surface Electromagnetic Wave-Based Wireless Communication System for Mines rth Environ. Sc View the article online for updates and enhancements.

Advanced Compact 5G MIMO Base Station for Sub-6 GHz

Jun 16, 2025 · A novel compact 5G multiple-input-multiple-output (MIMO) base station (5G-BS) is introduced for enhancing communications in underground mine environments. The structure

New Research Optimizes Wireless

Dec 4, 2024 · By optimizing the frequency bands and strategically positioning wireless communication base stations and antennas, mining companies can

Wireless Connectivity Enables Effective Communication

Nov 8, 2017 · The network is easily expanded and connectivity is ensured through redundancy as base station links are relocated and new mine walls are formed. Serving mobile users is a key

4G Fusion Communication System for Mines

System characteristics Underground Fusion 4G intrinsically safe fusion base station supports 4G, precise positioning, ring network switches and other modules, one station for multiple uses,

6 FAQs about [Wireless communication access base station for mines]

Why do mines need wireless communications?

Communications are an essential part of a mine's safety and operational management. In these challenging environments, wireless communications are advantageous to cabling due to robustness, coverage, and capability to communicate with mobile personnel and vehicles.

Can a mining machine be equipped with a base station?

Thus, both measurements show sufficient network coverage for underground mine communications. Moreover, the mining machinery can be equipped with base stations to further expand the network to the blind areas at the ends of the stope drifts.

What is a communications system in underground mines?

The management, monitoring, and control of the mining operations as well as the planning of the excavation play an important role. Communications bind all these operations together to maximize productivity. Various classifications of the communications systems in underground mines have been made.

Why do underground mining operators need wireless connectivity?

Underground mining operators have expressed the need for wireless connectivity to support a wide variety of use cases, including simple and basic connectivity for personnel, remote drilling and blasting control over autonomous and tele-remote-controlled vehicles, and person-to-person voice and video communications.

Are next-generation wireless systems effective in underground mines?

Next-generation wireless systems have been actively researched in the context of wireless sensor networks (WSNs). WSNs have been studied with the aims of improving safety and productivity and reducing operational costs in underground mines (Chehri et al., 2009, Bhattacharjee et al., 2012).

Why do mining companies need high-performing wireless networks?

To get the best out of these technologies and the digital applications they enable, mining companies need high-performing wireless connectivity in the mining areas. But many mines still rely on legacy networks that weren’t created to address the demands of ultra-broadband and mission-critical use cases.

Industry Information

- 35W solar street light price

- Best factory price bus tie breaker Buyer

- How much does an EK uninterruptible power supply cost

- Photovoltaic panel high power

- Power supply for secondary equipment in energy storage station

- Bolivia multifunctional outdoor power supply customization

- High quality 1 2 kva inverter in Yemen

- China China 500 watt power inverter producer

- Timor-Leste communication base station inverter grid-connected design description

- Large single-cell high-rate lithium battery pack

- Rcb circuit breaker in China in Ghana

- Guyana Industrial Park Photovoltaic Panel Manufacturer

- UPS battery cabinet circuit breaker

- Bulgarian container energy storage equipment manufacturer

- 1MWh energy storage project investment

- How big a battery capacity should the inverter be equipped with

- Spanish solar water pump manufacturer

- Solar Photochemical System

- Bamako Energy Storage Power Station

- Future Trends of Double Glass Modules

- How many 5G base stations does Senegal Telecom have

- Cook Islands Industrial UPS Uninterruptible Power Supply Brands

- Kuala Lumpur Portable Energy Storage Battery Price Quote

Commercial & Industrial Solar Storage Market Growth

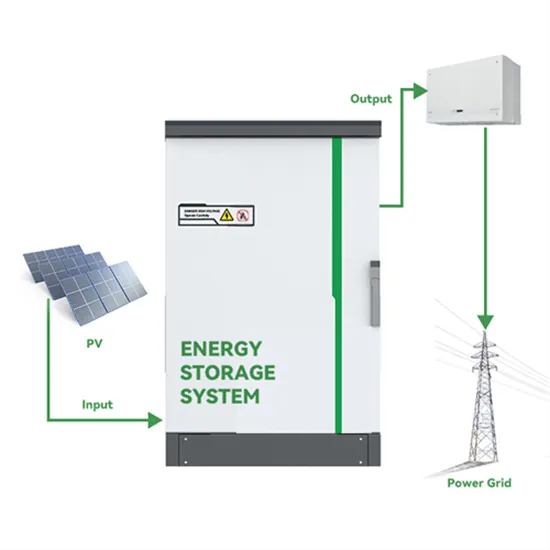

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

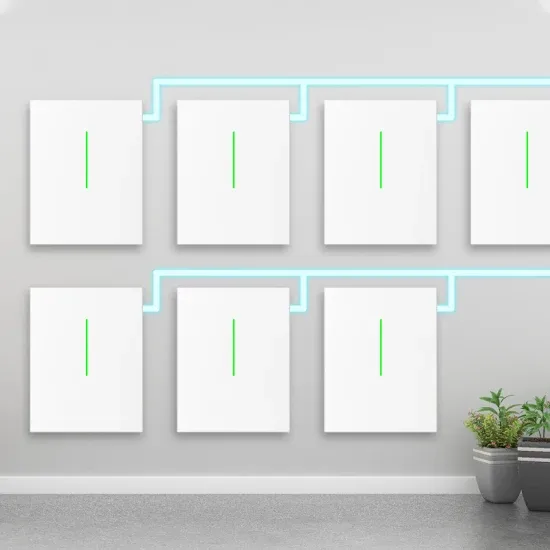

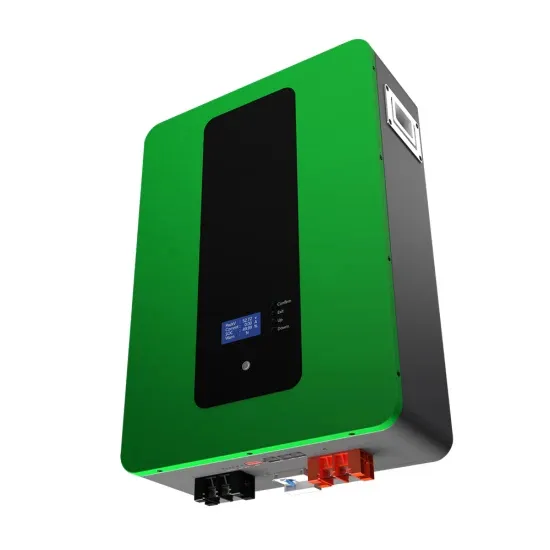

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.