ELECTROMAGNETIC CATAPULT INERTIAL ENERGY STORAGE FLYWHEEL

Electromagnetic catapult inertial energy storage flywheel Flywheel energy storage (FES) works by accelerating a rotor () to a very high speed and maintaining the energy in the system as .

What are the energy storage technologies for

Its application prospect is promising in the field of railway transportation, electromagnetic catapult, and the superconducting magnetic energy storage. the technology for manufacturing HTS

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

Research on Magnetic Coupling Flywheel Energy

May 14, 2023 · With the increasing pressure on energy and the environment, vehicle brake energy recovery technology is increasingly focused on reducing

Research on Electromagnetic System of Large Capacity Energy Storage

Jan 25, 2023 · Abstract: A large capacity and high-power flywheel energy storage system (FESS) is developed and applied to wind farms, focusing on the high efficiency design of the important

Electromagnetic catapult flywheel energy storage system

The electromagnetic catapult system of the USS Ford aircraft carrier uses flywheel energy storage, which can provide 200 MJ of instantaneous energy in 2 seconds

A Flywheel Energy Storage System with Active Magnetic

Jan 1, 2012 · A flywheel energy storage system (FESS) uses a high speed spinning mass (rotor) to store kinetic energy. The energy is input or output by a dual-direction motor/generator. To

flywheel energy storage electromagnetic catapult

A review of flywheel energy storage systems: state of the art and In this paper, state-of-the-art and future opportunities for flywheel energy storage systems are reviewed. The FESS

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Catapult Flywheel Energy Storage: The Physics-Powered Energy

Mar 9, 2025 · a 2-ton steel disk spinning at 25,000 RPM in a vacuum chamber - fast enough to store enough energy to power your home for days. This isn''t sci-fi, it''s catapult flywheel energy

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel energy storage principle of electromagnetic catapult

How can flywheels be more competitive to batteries? The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more

How Things Work: Electromagnetic Catapults

Nov 16, 2013 · The same energy is then used to return the carriage to its starting position. An electromagnetic catapult can launch every 45 seconds.

Electromagnetic Aircraft Launch System

The same is true with energy storage devices, which would be analogous to the steam catapult''s steam accumulator. The low energy density of the steam

Energy Storage Flywheel Electromagnetic Field: The Future

Nov 22, 2019 · Why Flywheel Energy Storage Is Stealing the Spotlight Imagine a technology that stores energy like a spinning top—simple, fast, and incredibly efficient. That''s flywheel energy

Electromagnetic catapult flywheel energy storage system

The principle of flywheel energy storage FESS technology originates from aerospace technology. Its working principle is based on the use of electricity as the driving force to drive the flywheel

Flywheel catapult

Jun 20, 2017 · A catapult and flywheel technology, applied in the field of flywheel catapult, can solve the problems of high use cost, high manufacturing cost of

Electromagnetic Catapult and Flywheel Energy Storage: The

Enter electromagnetic catapults – the 21st-century answer to steam-powered launches – now supercharged by flywheel energy storage systems (FESS). But why are militaries and

electromagnetic catapult and flywheel energy storage

The electromagnetic catapult system of the USS Ford aircraft carrier uses flywheel energy storage, which can provide 200 MJ of instantaneous energy in 2 seconds without affecting the

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Schematic diagram of energy storage electromagnetic catapult

A Comprehensive Review on Energy Storage Systems: Types, Comparison, Current Scenario, Applications, Barriers, and Potential Solutions Driven by global concerns about the climate

principle and application of energy storage electromagnetic catapult

A hybrid power system for unmanned aerial vehicle electromagnetic The strategy is using the Buck circuit to charge the super capacitor with constant current and using the Boost circuit to

Luxembourg electromagnetic catapult flywheel energy storage

The Integrating Tidal Energy into the European Grid (ITEG) project aims to generate a clean, predictable energy supply from renewable sources in areas with weak electricity networks.

The Ford-class Carrier''s EMALS Catapult Is

Jan 28, 2025 · The EMALS is an electromagnetic catapult that relies upon a linear induction motor, rather than a traditional steam piston, to launch aircraft. The

Flywheel energy storage principle of electromagnetic catapult

How does Flywheel energy storage work? Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational

Flywheel energy storage electromagnetic catapult

A review of energy storage types, applications and recent developments. S. Koohi-Fayegh, M.A. Rosen, in Journal of Energy Storage, 2020 2.4 Flywheel energy storage. Flywheel energy

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Energy storage flywheel for electromagnetic catapult of

Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Fu rthermore,flywheel batteries have high power density and a

Why does electromagnetic catapult use flywheel energy storage

Are flywheel energy storage systems feasible? Accepted: 02 March 2024 Abstract - This study gives a critical review of flywheel energy storage systems and their feasibility in various

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Advantages and disadvantages of energy storage electromagnetic catapult

Electromagnetic aircraft launch system-EMALS The US Navy had foreseen the substantial capabilities of an electromagnetic catapult in the 1940s and built a prototype. However, it was

Energy storage flywheel electromagnetic field

Flywheel energy storage system (FESS), as a kind of energy storage systems (ESSs), can effectively convert electrical energy and mechanical energy to accomplish energy

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

Flywheel Energy Storage

Flywheel energy storage, an innovative mechanical energy storage method, will hold a significant position in the future energy storage field.

Energy storage fly wheel of aircraft carrier catapult

By using the energy storage fly wheel, the catapult can drag an aircraft and uniformly speeds up to be at the speed required by the aircraft for takeoff within a 2.45second timer period, the fly

Theoretical calculation and analysis of electromagnetic

Nov 15, 2024 · This article presents a high-temperature superconducting flywheel energy storage system with zero-flux coils. This system features a straightforward structure, substantial

6 FAQs about [How big is the energy storage flywheel of the electromagnetic catapult ]

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is a flywheel energy storage system?

1. Introduction The flywheel energy storage system [1, 2] is a highly promising technology for efficient energy storage, comprising a flywheel rotor , bearings [, , ], vacuum technologies, and motor [, , , , , , ].

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

How does a flywheel work?

The power system delivers electrical energy to the flywheel device. Discharge: The process converts the mechanical energy consumed by the rotation of the flywheel into electrical energy and transmits it out, the drive motor operates as a generator, and the speed of the flywheel will decrease accordingly.

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

How can we verify the accuracy of a flywheel energy storage system?

The correctness of the calculation results was verified by conducting electromagnetic analysis on the unit model of the electric suspension structure of the flywheel energy storage system, and comparing the analytical results with those obtained from 3D finite element simulation (Figs. 4 and 5).

Industry Information

- New cylindrical lithium battery manufacturer

- South Sudan BMS lithium battery manufacturer

- Equipment costs of energy storage system

- Inverter EK output voltage is low

- Smart solar inverter in China in Cairo

- Introduction to Outdoor Solar Lights

- Azerbaijan uses bifacial solar panels

- Barbados new energy storage customization

- Outdoor power battery charging pile fast charging

- What does wind power storage peak load regulation mean

- Lithium phosphate battery service life of energy storage cabinet

- Factory price serket breaker in Italy

- Huawei Ouagadougou photovoltaic panels

- New Energy Storage Industrial Base

- High power solar tracking system

- Vientiane pulls solar photovoltaic panels

- Estonia BESS Uninterruptible Power Supply

- Nitrogen zinc flow battery

- Wholesale 12v circuit breaker in Jamaica

- Huawei Energy Storage Cabinet System Access Solution

- Branded photovoltaic panels generate more electricity

- Portable energy storage power supply development

- 5g base station communication capability

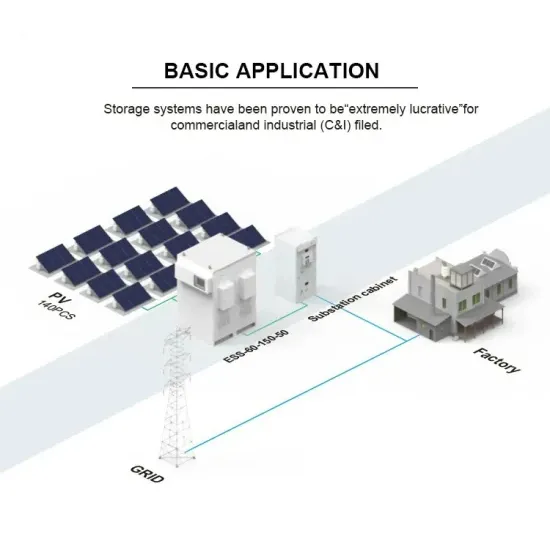

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.