Safe Operating Area (SOA) Ratings of AC Inverter Duty

Jan 14, 2025 · Benefits ted with an AC speed control (inverter), the motor or gearmotor speed can be easily matched to varying application loads. Pacesetter gearmotors and motors are more

How Inverter Drives Control AC Induction Motors

Mar 17, 2025 · Conclusion In summary, Inverter Drives are crucial for controlling AC induction motors, employing advanced techniques such as Pulse Width Modulation. These drives

What is AC Frequency Inverter

Sep 14, 2024 · The AC frequency inverter (VFD) is a motor drive, intended for electromechanical drive systems, that regulates the speed and torque of AC motors by varying the motor input

Frequency Inverters for Your Drives | SEW‑EURODRIVE

SEW‑EURODRIVE produces high-quality frequency inverters for controlling the speed of AC motors in your applications and production processes.

BALDOR-RELIANCE RPM AC High-performance Inverter

RPM AC, a truly feature-rich lineup From its beginnings in 1987, RPM AC has always represented a high-performance, power dense, true variable speed motor family. Since those early days,

SPECIFICATION GUIDE ELECTRIC MOTORS

Sep 23, 2024 · Specification of Electric Motors WEG, which began in 1961 as a small factory of electric motors, has become a leading global supplier of electronic products for different

VFD Motor Turn Down Ratio | Eng-Tips

May 31, 2006 · On inverter duty motors designed to operate down to zero speed, the turndown ratio becomes meaningless. Some manufacturers show 1000/1 turndown ratio for those

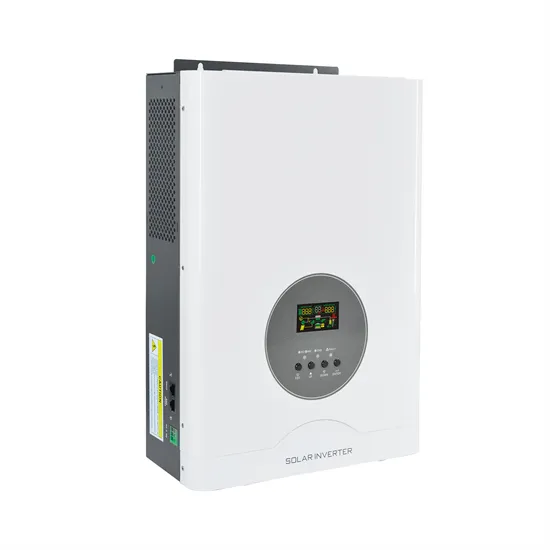

Inverter Size Calculator [Power Inverter, AC, DC,

Feb 7, 2025 · Calculate the ideal inverter size with the Inverter Size Calculator. Perfect for selecting inverters for homes, solar panels, or vehicles based on

Solar inverter sizing: Choose the right size

Figure 1: Inverter AC output over the course of a day for a system with a low DC-to-AC ratio (purple curve) and high DC-to-AC ratio (green curve). The chart

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · Inverter programming should include adjustments for parameters such as speed control, voltage-to-frequency ratio, and torque characteristics,

SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

ptimal motor and inverter capacities selection. This chapter provides you with information about the inverter output torque characteristics, capacity selection procedure, and equations for

TECHNICAL CATALOG RPM AC & V*S Master motors

The RPM AC Quick Ship program allows customers to obtain selected modifications on RPM AC motors in much shorter time frames than ordering a custom RPM AC motor.

Servo Driver vs. Inverter: What Are the Key

Feb 5, 2025 · Inverter: Inverters are simpler in design and operation, making them easier to install and maintain. They are often plug-and-play solutions for basic

AC Motor Guide

Aug 20, 2025 · This guide reviews the fundamentals of AC Motors in motion control and industrial automation applications. Learn about AC motor types,

87 Hz motor technique with AC drives (Part 1)

As the speed of the motor is 1,7 times bigger than at 50 Hz it is compensated by choosing the gear ratio being 1,7 times bigger. The result obtained is a 1,7 times bigger output ratio of the

8 Project Planning for AC Motors with Inverter

Aug 1, 2014 · SEW-EURODRIVE offers the following inverter series: MOVITRAC® B: Compact and inexpensive frequency inverter for the power range 0.3-175HP. Single-phase and three

AKX00057-1

Jul 26, 2018 · Rotation speed control of AC motors using an inverter The rotation speed, or RPM, of a three-phase AC induction motor is represented by the following equation, which indicates

A Guide to Inverter Drives | RS

Sep 30, 2024 · Inverter drives, also known as variable frequency drives (VFDs) or frequency inverters, are electronic devices used to control the speed and

SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES This chapter describes the optimal motor and inverter capacities selection. This chapter provides you with information

Everything You Need to Know About Inverter

Apr 20, 2025 · At Power Northwest, we understand that every solar system is unique to every home or business. For this reason, one of the most important

applications.PDF

Jan 20, 2015 · An electronic converter which converts Direct Current (DC) to Alternating Current (AC) is known as an inverter. Electronic speed controllers for AC motors usually convert the

CSM_Inverter_TG_E_1_2

Mar 31, 2019 · The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed

Turndown ratio in AC motor speed control

Jun 29, 2020 · Choosing the right motor and VFD type depends on a variety of factors; however, it is necessary to analyze how the motor changes when the speed is reduced.

Products

Inverters - AC Motor Drives With modern power electronics and advanced microprocessor technology, Delta''s AC Motor Drives are able to efficiently

Safe Operating Area (SOA) Ratings of AC Inverter Duty

Jan 14, 2025 · Benefits Inverter duty, three-phase gearmotors ofer performance improvements over comparable single-phase units. When operated with an AC speed control (inverter), the

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Frequency Inverters for Your Drives | SEW‑EURODRIVE

Subsequently, the operative DC-AC inverter on the motor side generates an AC voltage with the output frequency required by the application. The resulting voltage-to-frequency ratio then

What is Electric Motor Turndown Ratio?

May 17, 2023 · Basic "inverter duty" or "inverter ready" motors have a turndown ratio of 20:1 when combined with scalar VFD control. And inverter duty motors have a turndown ratio of 1000:1 or

Selecting the Proper Inverter / Frequency Converter for your

4 days ago · Whenever possible, we recommend using the low-frequency transformer isolated GS or Classic Series models for motor loads. The formula to use for all inverters which are to

How to Analyze and Calculate True Efficiency in Inverters

4 days ago · Inverters are essential for converting DC power into usable AC power, but their efficiency, measured by the ratio of output to input power—determines their true performance.

Induction Motor Control through AC/DC/AC Converters

Jul 31, 2025 · Abstract— We are considering the problem of controlling inductions motors driven through AC/DC rectifiers and DC/AC inverters. The control objectives are threefold: (i) forcing

DC/AC inverter oversizing ratio – what is the optimal

Mar 2, 2021 · The ratio of the DC output power of a PV array to the total inverter AC output capacity. For example, a solar PV array of 13 MW combined STC output power connected to a

AC Inverter/Vector Duty Motors

Industrial electric motors are available for most general purpose applications and processes. However, some AC Variable Speed applications require constant torque at zero speed.

Inverter Duty Motors vs. Standard Motors | IBT

Feb 25, 2025 · Learn all about inverter duty motors vs. standard motors and see which one is the best for your application in your specific industry.

6 FAQs about [AC inverter ratio for motor]

What is AC motor inverter design?

AC motor inverter design refers to the engineering and technology involved in creating devices that convert direct current (DC) into alternating current (AC) to control the speed of AC motors. These inverters modulate the voltage and frequency supplied to the motor, thus allowing precise control of its speed and torque.

How does an inverter control AC motor speed?

The inverter circuit functions to control AC motor speed by converting direct current (DC) into alternating current (AC). First, the inverter receives DC from a power source, often a battery or a rectified supply. Next, it uses power electronic devices, such as transistors, to switch the DC voltage on and off rapidly.

What makes a good AC motor inverter?

Lastly, using advanced materials and components can improve inverter efficiency. Silicon carbide (SiC) and gallium nitride (GaN) semiconductors offer better performance than traditional silicon-based devices. Overall, a well-designed AC motor inverter ensures reliable and efficient speed control for three-phase drives.

How does an inverter work?

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor.

Why are power electronics important in AC motor inverter design?

Power electronics are crucial in AC motor inverter design because they control the conversion and management of electrical energy to optimize motor performance. They enable the efficient operation of AC motors by adjusting voltage and frequency, which in turn controls the speed and torque of the motor.

Do you need an inverter for a motor control application?

Need for an inverter for motor control applications The rotation speed, or RPM, of a three-phase AC induction motor is represented by the following equation, which indicates that the RPM is inversely proportional to the number of poles (P) and proportional to frequency (f).

Industry Information

- Huawei Barbados Energy Storage Power Brand

- Local governments increase energy storage projects

- Thimphu Power Plant wind solar and storage integration

- Chisinau outdoor power bms merchants

- 220v to high voltage inverter

- How much does Bandar Seri Begawan solar photovoltaic panels cost

- Mbabane Energy Storage Photovoltaic

- Azerbaijan outdoor power supply brand ranking

- Roman Photovoltaic Energy Storage Lithium Battery

- Bosnia and Herzegovina generator inverter manufacturer

- Latest on energy storage batteries

- Bulgaria container house wholesale

- Rechargeable solar powered light

- The development prospects of energy storage substation

- Prices of photovoltaic panels in Belgrade

- Gonghe Solar Monitoring Power Supply System Manufacturer

- Tehran energy storage system manufacturer

- Silicon content of photovoltaic glass

- Moscow 9m6 solar air conditioner

- Localizing energy storage in Bamako

- Energy storage power supply field

- Solar photovoltaic panel cost in the Middle East

- How many watts can a solar street light produce

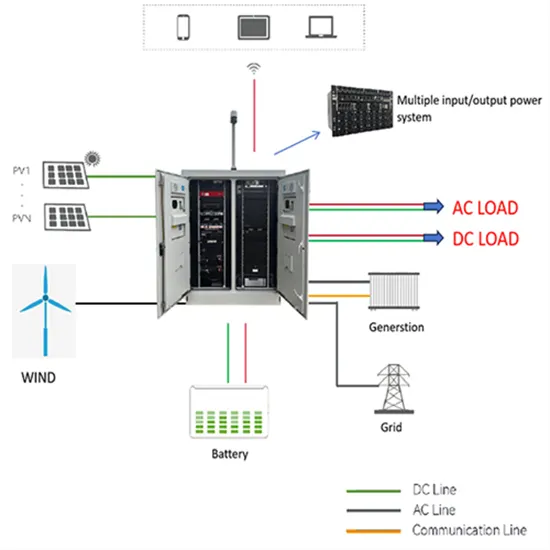

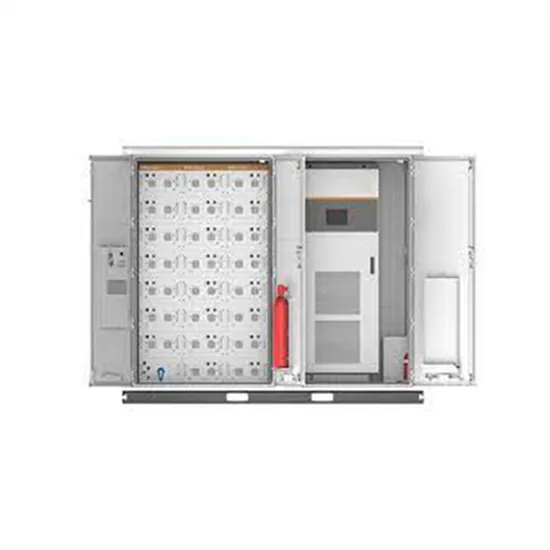

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

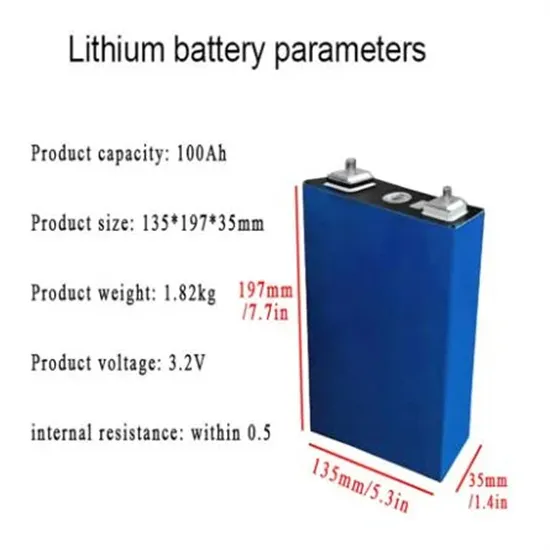

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.