Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

Battery Swelling

Lithium-ion batteries are key components of the electrification of the transport and traffic sector. Research and development along with comprehensive quality assurance play an important

High-voltage battery packs

Aug 13, 2025 · Lithium-iron phosphate (LFP) batteries are redefining sustainable power for electric vehicles. Engineered to enable faster charging, longer life

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Key Points of Lithium Battery PACK

Jun 27, 2024 · Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and long cycle

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Custom Lithium Battery Pack Manufacturing: A

Mar 1, 2025 · Our methodology ensures every custom lithium-ion battery pack – from ultra-low-temperature 18650 configurations to high-voltage LiFePO4

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

High voltage battery development | Magna

Sep 24, 2023 · Battery development for a high voltage battery electric vehicle is one of the most important and complex challenges of any BEV project.

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · Production Line The production line for lithium battery packs is a highly integrated system designed to streamline the manufacturing process

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

Lithos Energy

Lithos is founded on a world-class engineering team that is co-located with production to solve problems and iterate fast. From early specifications,

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

What is High Voltage Battery – The

Jan 6, 2025 · The term "high voltage" refers to the capability of these batteries to deliver higher electrical energy, which is achieved by connecting multiple cells

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · These battery packs are critical components in electric vehicles (EVs), energy storage systems, and various portable electronic devices. Key

Understanding High Voltage Lithium-Ion Battery

Mar 28, 2025 · Before investing in a high voltage lithium-ion battery, make sure you''re well-informed. This guide provides a comprehensive overview, covering

Energy Storage Battery PACK Comprehensive

In the field of electrochemical energy storage, lithium-ion battery energy storage is currently the most mature and rapidly developing technology. Among them,

High-Voltage Electrolyte Chemistry for Lithium

Feb 18, 2022 · Under this content, this review first introduces the degradation mechanism of lithium batteries under high cutoff voltage, and then presents an

Lithium-ion Battery PACK Tech Explained

Key features of a lithium battery PACK include a high degree of consistency, lower cycle life compared to single batteries, specific usage conditions, protection requirements for voltage

ABS Ramps Up Commercial-Vehicle Battery-Pack Assembly

Jul 31, 2025 · High-voltage battery pack production is slated to start in October 2022 for commercial-vehicle applications. "Everything that we learn on the prototype line in Michigan

EV/PHEV/HEV Battery Packs for Electric Vehicles

Highly Integrated EV Battery Packs Excellence in Power with Compatibility for All Vehicle Models Utilizing an industry-leading and diverse technological

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Festo offers high-precision automation components for battery manufacturing with pneumatic and electric actuators, valves, and handling systems to improve electrode coating,

High Voltage Battery Packs (100-800V) – NPP

The high-voltage battery system is usually faster than the low-voltage battery charge and discharge, the voltage above 400V belongs to the high-voltage

High-voltage batteries: how to make them safe

Sep 12, 2024 · High-voltage batteries are therefore essential to meet the needs of vehicles with high-powered engines and which as a result require high

From cell to powerhouse: The journey of battery pack production

Aug 8, 2024 · However, to ensure that the large high-voltage lithium-ion battery packs provide as much storage capacity as possible not only at the beginning of their life cycle, but over their

Leading Battery Pack Manufacturers Worldwide:

Aug 8, 2024 · Explore the top 10 global battery pack manufacturers powering devices from smartphones to EVs, with insights into their innovations and

Challenges in Li-ion battery high-voltage technology and

Apr 1, 2024 · The production of a benzimidazole lithium salt through substitution of a –CH3 for –CF 3 on the imidazole ring stabilized lithium hexafluorophosphate through a Lewis acid-base

Where the BMW Group will make its next

Jul 19, 2024 · The Neue Klasse will usher in a new era of fully electric driving at the BMW Group – the success of which will depend heavily on the production

High-Voltage Batteries: Basics & Applications

Feb 28, 2025 · High voltage batteries are a relative concept in the battery-powered equipment market. Generally, there are two main types available:

Press Release | Media | LG

Jul 2, 2024 · With the latest supply deal, LG Energy Solution has further expanded its product portfolio in pouch-type batteries encompassing various chemistries such as high-nickel NCMA,

8 Important Production Steps of Lithium Battery

Measure the data of initial voltage and internal resistance, and remove defective cells such as PVC film damage, missing surface pads, rust, deformation, and

6 FAQs about [High voltage lithium battery pack production]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Industry Information

- Solar energy prices for photovoltaic panels in Paraguay

- Canberra photovoltaic power station energy storage design

- High quality 2000w solar inverter for sale Factory

- Do energy storage power stations require emergency management

- Bofat communication base station wind power

- Factory operation of energy storage cabinet

- How big of an inverter can 24v drive

- Mbabane Uninterruptible Power Supply Company

- Wellington Grid-connected Inverter Factory

- How big an inverter should I use for a 720w solar panel

- Energy storage power mAh

- How much is solar air conditioning in Baku

- How much is the shipping cost per square meter for rural solar photovoltaic panels

- HTC base station does not respond when plugged into power source

- Base station power supply new thunder energy

- Venezuela ups distribution cabinet battery cabinet price

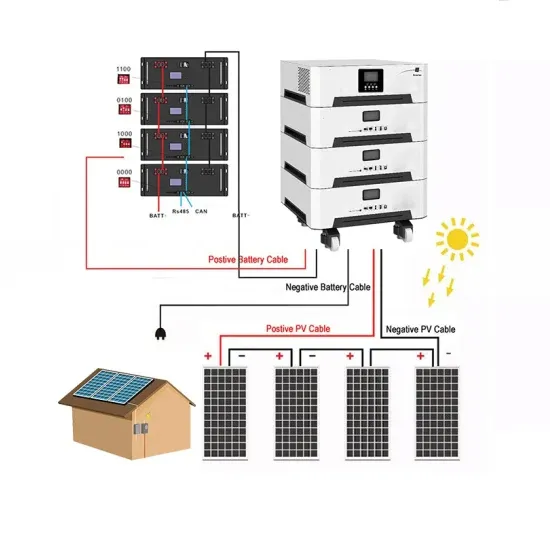

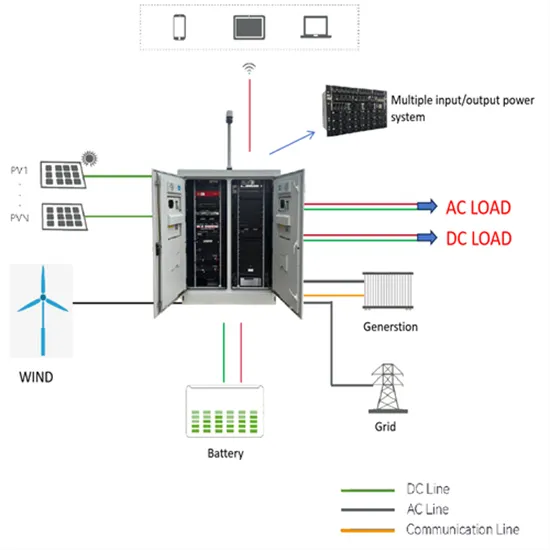

- Photovoltaic solar energy system

- Spanish energy storage fire protection solution

- Remote solar power supply system

- Solid state breaker for sale in Bulgaria

- Where can I find a battery cabinet in Vilnius

- Price of UPS uninterruptible power supply for North Macedonia data center

- HJ battery cabinet replacement system

Commercial & Industrial Solar Storage Market Growth

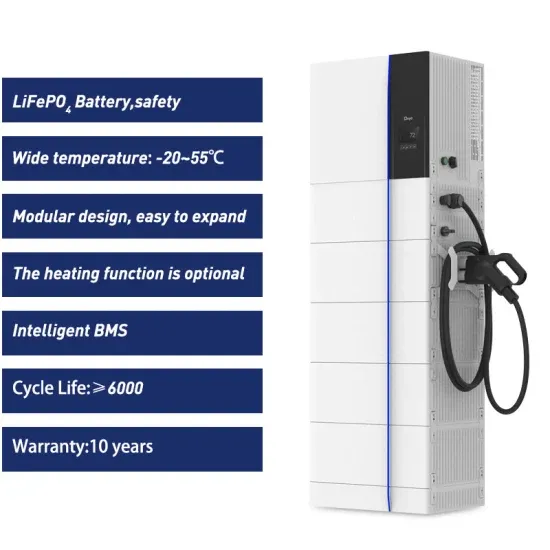

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.