working principle of air-cooled energy storage cabinet

In the energy storage process, the high-pressure air absorbs cold energy to be cooled down and liquefied. In the energy release process, the liquid air releases

Structure of air-cooled energy storage cabinet

Mar 3, 2024 · The utility model discloses an air cooling heat dissipation structure of an energy storage cabinet, which relates to the technical field of air cooling heat dissipation and

AIR COOLED ENERGY STORAGE CABINET

Working principle diagram of energy storage cabinet There are many different types of battery technologies, based on different chemical elements and reactions. The most common, today,

working principle of air-cooled container energy storage

Effect of thermal storage and heat exchanger on compressed air energy storage systems A-CAES was first proposed in 1972 [17] g. 2 illustrates the working principle of A-CAES: the

Cooling principle of water-cooled energy storage cabinet

Why is water used as cold energy storage material in data centers? Water is generally used as cold energy storage material in data centers,because of its low price,high specific heat

Working principle of air-cooled energy storage battery box

Liquid air energy storage (LAES) uses air as both the storage medium and working fluid, and it falls into the broad category of thermo-mechanical energy storage technologies. The LAES

working principle of air-cooled container energy storage

Among all energy storage systems, the compressed air energy storage (CAES) as mechanical energy storage has shown its unique eligibility in terms of clean storage medium, scalability,

Working principle of energy storage liquid-cooled battery cabinet

The working principle of the liquid cooling system in the energy storage cabinet is mainly divided into the following steps: Coolant circulation: The core of the liquid cooling system is the

liquid cooling energy storage cabinet principle

By interacting with our online customer service, you''ll gain a deep understanding of the various liquid cooling energy storage cabinet principle featured in our extensive catalog, such as high

Working Principle of Air-Cooled Energy Storage Battery Cabinet

Can a battery container fan improve air ventilation? The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research.

Working principle of industrial and commercial liquid

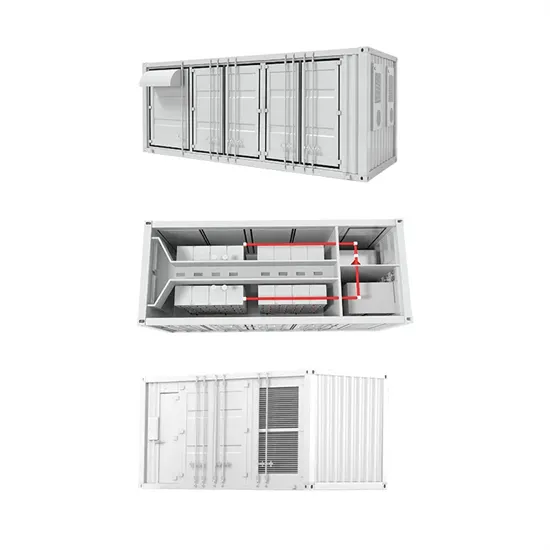

This article will provide a detailed introduction to the working principles of liquid-cooled ESS container systems, revealing their unique advantages in energy storage. with each module

air-cooled energy storage principle diagram

Comparison of advanced air liquefaction systems in Liquid Air Energy In the pre-cooled Linde system, chlorofluoromethane was applied as the working medium. Liquid Air Energy

Liquid Cooling Container Energy Storage System Design

Huijue''''s cutting-edge Liquid-Cooled Energy Storage Container System, armed with 280Ah lithium iron phosphate batteries, fuses cutting-edge design principles. Boasting intelligent liquid

working principle of air-cooled radiator of energy storage cabinet

The air-cooled chiller is a kind of industrial chiller,and the main working principle is not much different from that of the water-cooled chiller. Air-cooled chiller is a machine that cools water at

Working principle of energy storage cabinet liquid

Amid the global energy transition,the importance of energy storage technology is increasingly prominent. The liquid-cooled ESS container system,with its efficient temperature control and

Video of the working principle of air-cooled energy storage cabinet

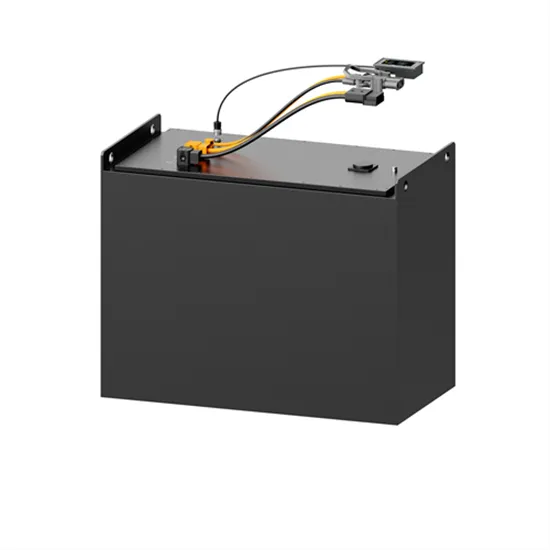

working principle of air-cooled battery energy storage cabinet Features of a 20-feet air-cooled cabinet c&i energy storage systems Battery Modular design: With a battery modular design,

344kWh Battery Storage Cabinet (eFLEX BESS)

AceOn offer a liquid cooled 344kWh battery cabinet solution. The ultra safe Lithium Ion Phosphate (LFP) battery cabinet can be connected in parallel to a

power saving principle of liquid cooling energy storage cabinet

By interacting with our online customer service, you''ll gain a deep understanding of the various power saving principle of liquid cooling energy storage cabinet featured in our extensive

Working Principle of Air-Cooled Energy Storage Battery Cabinet

The utility model discloses an air-cooled energy storage battery cabinet, which belongs to the technical field of battery cabinets and comprises a battery cabinet body, wherein an air outlet

Air cooling principle of energy storage cabinet

Liquid Air Energy Storage (LAES) applies electricity to cool air until it liquefies, then stores the liquid air in a tank. The liquid air is then returned to a gaseous state (either by

Working principle of energy storage cabinet liquid

Liquid air energy storage (LAES) uses air as both the storage medium and working fluid, and it falls into the broad category of thermo-mechanical energy storage technologies. The LAES

On-site installation of air-cooled energy storage cabinet

This 60kwh outdoor air cooled energy storage system cabinet consists of high safety, long life lithium iron phosphate batteries, advanced BMS, battery energy storage inverter, high voltage

Liquid-cooled container energy storage system single set

Liquid-cooled battery storage system based on HiTHIUM prismatic LFP BESS Cells 314 Ahwith highest cyclic lifetime. Improved safety characteristics and specially optimised for the highest

Principle structure diagram of liquid cooling energy

Liquid-cooled energy storage cabinets significantly reduce the size of equipment through compact design and high-efficiency liquid cooling systems, while increasing power density and energy

WHAT IS THE WORKING PRINCIPLE OF THE AIR

racteristics and efficiency of compressed air energy storage systems . Compressed air energy storage systems are sub divided into three categories: di sually by simply attaching more air

What is the principle of air-cooled energy storage | NenPower

Aug 18, 2024 · In summary, the principle of air-cooled energy storage brings together crucial elements of modern energy management. This innovative technology leverages

WORKING PRINCIPLE OF INTEGRATED ENERGY

What is a 30kW photovoltaic storage integrated machine? Among them,the 30KW photovoltaic storage integrated machine has a DC voltage of 200~850V,supports MPPT,STS,PCS

working principle of energy storage water tank of air-cooled

Air-cooled energy storage is a technology that uses natural wind or mechanical power to cool and store air to release cold energy when needed. Compared with traditional water cooling and

Working principle of energy storage cabinet liquid

Photovoltaic-driven liquid air energy storage system for combined cooling, heating and power towards zero-energy buildings follows the basic principle of passive ultra

Electrical Principle of Liquid Cooling Energy Storage

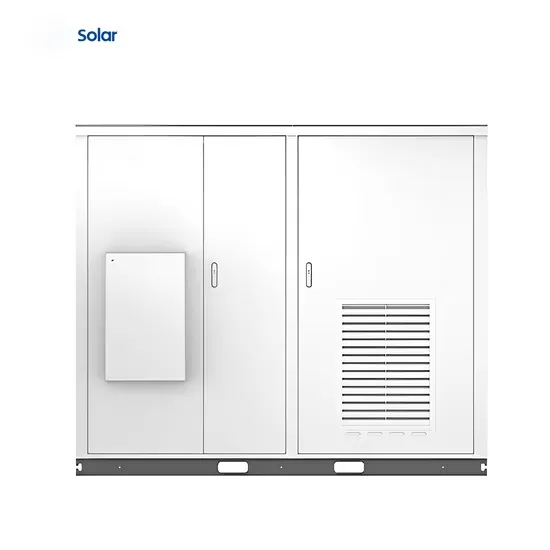

The rack-type energy storage system supports user-side energy response scheduling and remote duty operation and maintenance, supports parallel/off-grid operation, and can be widely used

Air cooling principle of energy storage cabinet

Why does air cooling lag along in energy storage systems? Abstract: With the energy density increase of energy storage systems (ESSs),air cooling,as a traditional cooling method,limps

Liquid cooling energy storage cabinet principle

Key Features of Battery Cabinet Systems. High Efficiency and Modularity: Modern battery cabinet systems, such as those from CHAM Battery, offer intelligent liquid cooling to maintain optimal

Air-cooled energy storage technology principle

Liquid air energy storage (LAES) uses air as both the storage medium and working fluid, it falls into the broad category of thermo-mechanical energy storage technologies.

Air-cooled energy storage technology principle

Air-Cooled Condenser: Definition, Components, Types, Working Air-cooled condensers provide flexibility in system placement as they are not dependent on proximity to a water source. This

Industry Information

- Communication base station hybrid energy outsourcing

- Ups battery cabinet dual wind power

- Middle East new energy and energy storage policy

- Uninterruptible power supply equipment model

- Can a communication base station battery energy storage system be built in a hospital

- Solar energy collection assists energy storage cabinet

- Factory power inverter manufacturers

- Which unit is responsible for the communication base station energy management system

- Solar panel power storage container power supply

- Israel LNG energy storage project

- Sodium-ion battery for energy storage

- Solar inverter background price

- Operation cost of communication base station inverter

- Photovoltaic glass and silicon panels

- Amman energy storage system manufacturer recommendation

- 5kw solar system with battery in Burundi

- Solar photovoltaic inverter 10 000 watts

- Lithium battery station cabinet contains station cabinet

- Japanese photovoltaic curtain wall manufacturer

- Best high quality 1000 va inverter Factory

- Greek environmentally friendly energy storage battery batch customization

- Pyongyang communication base station battery energy storage system cabinet supplier

- Wholesale 200w power inverter in Jordan

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.