China''s PV Industry from 2024 to 2025:

Mar 3, 2025 · China''s PV manufacturing industry demonstrated its strong capabilities in 2024. The production of polysilicon, wafers, cells and modules

Spring 2024 Solar Industry Update

Jun 14, 2024 · PV System and Component Pricing The median system price of large-scale utility-owned PV systems in 2023 was $1.27/Wac—relatively flat since 2018. The median price for

Solar Photovoltaic (PV) Cell Market Size & Share

Aug 7, 2023 · Based on technology, the Solar Photovoltaic (PV) Cell market is divided into Thin Film, Multi-Crystalline Silicon, and Mono-Crystalline silicon

International Solar PV and BESS Manufacturing Trends

Mar 24, 2025 · CEF notes the IEA consistently underestimates the pace of the global solar PV, BESS and electric vehicle (EV) disruption and the growth in manufacturing capacity. Analysing

U.S. solar manufacturing boom "real — but

Apr 1, 2025 · The U.S. is on track to reach 13 GW of cell manufacturing capacity and 65 GW of module assembly in 2025, said a report from Clean Energy

Solar PV manufacturing capacity by region and component

Jul 3, 2025 · In 2023, China dominated the global solar PV supply chain, accounting for a polysilicon manufacturing capacity of ***** gigawatts, a wafer production capacity of ***

Designing New Materials for Photovoltaics

This report provides a global survey from IEA PVPS member countries of efforts being made to design new materials for photovoltaic cell and module applications. The report is organized by

Understanding the evolution of photovoltaic value chain

Dec 1, 2022 · The PV value chain is gradually disassembled and modularized in the developing PV technology. There is a difference in developing various components for the PV value chain

China''s photovoltaic industry continues its rise

Oct 14, 2024 · Driven by China''s dual-carbon goal of reaching peak carbon emissions and attaining carbon neutrality, Chinese PV companies have

Solar PV equipment production by region and component

Jul 16, 2025 · In 2023, the demand for solar photovoltaic cells in China stood at *** gigawatts.

Introduction to Photovoltaic Solar Energy

Jan 1, 2025 · Photovoltaic (PV) solar cells transform solar irradiance into electricity. Solar cells, primarily made of crystalline silicon, are assembled in arrays to produce PV modules. PV

Progress of PV cell technology: Feasibility of building

Jul 1, 2023 · The existence of any established PV technology, which is in mass production and market entry of any new PV technology, which are proposed and under investigation, largely

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · Photovoltaic modules, or solar modules, are devices that gather energy from the sun and convert it into electrical power through the use of semiconductor-based cells. A

Solar PV cell materials and technologies: Analyzing the

Jan 1, 2021 · In last five years, a remarkable development has been observed in the photovoltaic (PV) cell technology. To overcome the consequences on global warming due to fossil fuel

The State of the Solar Industry

Apr 4, 2024 · But, PV Deployment Too Slow to Decarbonize Grid by 2035 Projected PV deployment (green bars) is growing as a result of the Inflation Reduction Act, but is not on

Understanding the Composition of a Solar Cell

Jun 1, 2021 · A photovoltaic cell is a p-n junction on a thin, flat wafer. A p-n junction is an intersection between adjacent layers of p-type and n-type

A comprehensive evaluation of solar cell technologies,

Jun 1, 2024 · In-depth assessments of cutting-edge solar cell technologies, emerging materials, loss mechanisms, and performance enhancement techniques are presente

PV cells and modules

Sep 23, 2020 · The key components of photovoltaic (PV) systems are PV modules representing basic devices, which are able to operate durably in outdoor conditions. PV modules can be

Solar Cell: Definition, Components, and Uses

Aug 15, 2024 · A solar cell, sometimes called a photovoltaic cell, constitutes an electronic apparatus engineered to harness the photovoltaic effect, a process

Components of a Solar Panel: Complete Technical Guide

1 day ago · Understanding the components of a solar panel empowers informed decision-making when selecting photovoltaic systems. Each component—from photovoltaic cells and protective

Advancements in photovoltaic technology: A comprehensive

Apr 1, 2025 · PV technology is crucial for renewable energy and climate change mitigation. Perovskite Solar Cells (PSCs) offer efficiency gains but face stability challenges. Tandem and

Everything you need to know about photovoltaic

Mar 14, 2024 · A photovoltaic (PV) cell is the physical piece of equipment that converts light into electricity. PV cells usually consist of a number of different

Photovoltaics (PV) Market Size, Share, Trends

Photovoltaics Market by Material (Silicon, CIGS, CdTe, Perovskite, Organic Photovoltaic, Quantum Dot), Component (Modules, Inverters, BOS),

Solar Photovoltaics Supply Chain Review Report

Feb 24, 2022 · The supply chain for solar PV has two branches in the United States: crystalline silicon (c-Si) PV, which made up 84% of the U.S. market in

Global Photovoltaic Market Size, Size, Analysis

Global Photovoltaic Market Size, Share, and COVID-19 Impact Analysis, By Component Type (Modules, Inverters, and Balance of System), By Material (Silicon and Compounds), By Cell

Solar Power Plant – Types, Components, Layout

2 days ago · How a Photovoltaic Power Plant Works? Types of Solar Power Plant, Its construction, working, advantages and disadvantages.

Solar Photovoltaic Technology Basics

3 days ago · Learn the basics of how photovoltaic (PV) technology works with these resources from the DOE Solar Energy Technologies Office.

India: The Rising Power in Global Solar

May 1, 2024 · The export market is and will be a key source of demand for Indian solar PV cells and modules, particularly in case of limited Indian demand for

Executive summary – Solar PV Global Supply Chains

Aug 13, 2025 · Global capacity for manufacturing wafers and cells, which are key solar PV elements, and for assembling them into solar panels (also known as modules), exceeded

Summer 2024 Solar Industry Update

Aug 20, 2024 · Although they have a somewhat diversified set of buyers for their PV cells, almost all the PV modules they export go to the United States, introducing high risk for this market

China''s photovoltaic industry continues its rise

Oct 14, 2024 · Thanks to Chinese PV companies'' continuous technological innovation, enhanced independent R&D, and improved production efficiency,

6 FAQs about [Photovoltaic cell and component industry]

What are the key factors influencing the photovoltaics market?

Rapid developments in the solar energy sector in terms of power generation and utilization contribute to the increase in solar PV installations for various applications, driving the photovoltaics market. Product launches are expected to offer growth opportunities for market players in the next five years.

Who are the major players in the global photovoltaics market?

Jinko Solar (China), JA SOLAR Technology Co., Ltd. (China), Trinasolar (China), LONGi (China), Tongwei Co.Ltd (China) are major players in the photovoltaics market. The steady decrease in the price of PV systems and energy storage units has been a key growth driver for the global photovoltaics market.

How has global solar PV manufacturing capacity changed over the last decade?

Global solar PV manufacturing capacity has increasingly moved from Europe, Japan and the United States to China over the last decade. China has invested over USD 50 billion in new PV supply capacity – ten times more than Europe − and created more than 300 000 manufacturing jobs across the solar PV value chain since 2011.

Are there trends in photovoltaic (PV) integration across building and grid applications?

The investigation of recent case studies in Table 6 underscores developing trends and persistent patterns in photovoltaic (PV) integration across diverse building and grid applications.

What are the different types of PV cells?

The following are the primary categories that are used to classify PV cells, which are the fundamental components of solar energy systems: Crystalline silicon solar cells are the most common type of PV cell . They are made from silicon crystals, which are arranged in a highly ordered structure.

How many jobs will the solar PV industry create?

The solar PV industry could create 1 300 manufacturing jobs for each gigawatt of production capacity. The solar PV sector has the potential to double its number of direct manufacturing jobs to 1 million by 2030. The most job-intensive segments along the PV supply chain are module and cell manufacturing.

Industry Information

- High quality new circuit breaker for sale Wholesaler

- Communication base station inverter grid connection and signal

- Standards for wind power size of communication base stations

- Notification of the completion of Nordic energy storage project

- Cheap blown circuit breaker factory producer

- How much does the Bridgetown power inverter cost

- Advantages and disadvantages of energy storage pcs system

- Brand high power portable power bank

- Praia power frequency isolation 250kw inverter

- Wholesale 1600 amp switchgear in Oman

- Container outdoor power supply 2000W

- Energy storage container push-pull structure

- Solar panels plus on-site energy

- Ulaanbaatar Solar Power System Installation

- Baghdad 40-foot energy storage container factory

- Mobile power box modification

- DC screen battery cabinet price in East Africa

- Nassau Industrial Energy Storage Manufacturer Supply

- UPS battery cabinet a32 size

- How much does a super battery cabinet cost

- Asmara Independent Energy Storage Power Station

- Lima PV grid-connected inverter

- Kuwait mining UPS uninterruptible power supply price

Commercial & Industrial Solar Storage Market Growth

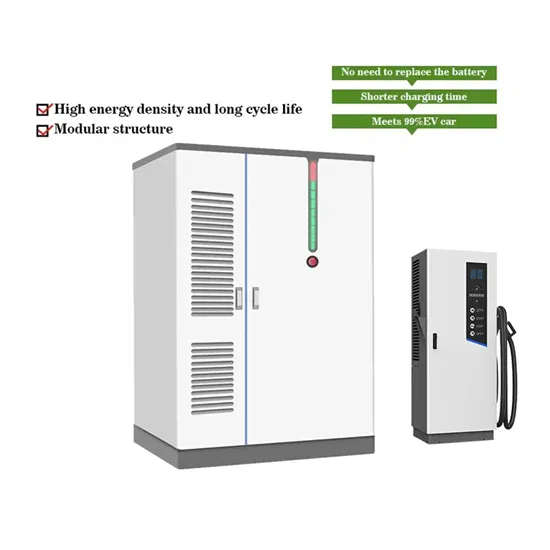

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.