Accuracy requirements for battery aging cabinets in battery PACK

Jun 30, 2025 · The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

What Is The Battery Compartment in The Energy

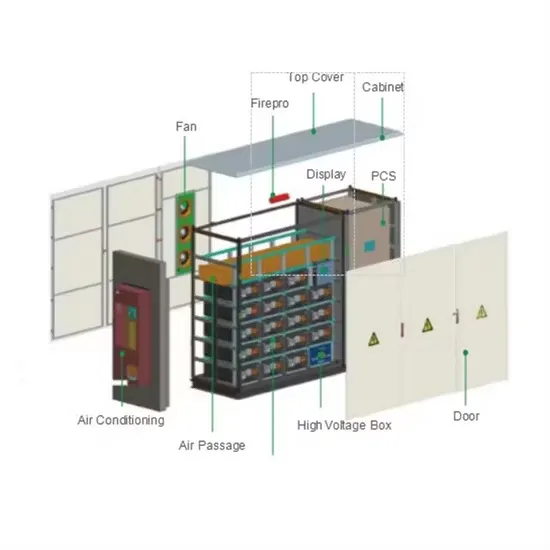

Mar 6, 2025 · Therefore, the first step in thermal management is to design a well-designed air conditioning and ventilation system, as well as a battery cell

ABS Cabinet Box (Enclosure/Box) for DIY Lithium Battery Pack

Introducing the ABS Cabinet (Enclosure) for Lithium Battery Pack, a robust and reliable solution for housing your lithium-ion battery cells. Designed to accommodate 12V/30AH or 24V/15AH

Install the Battery Modules in the Battery Cabinet

Install the battery modules on the shelves from top to bottom. NOTE: Pay special attention to the location of type A and type B battery modules. Reinstall the plate in front of the battery

Energy Storage Battery Pack Enclosure size optimization and

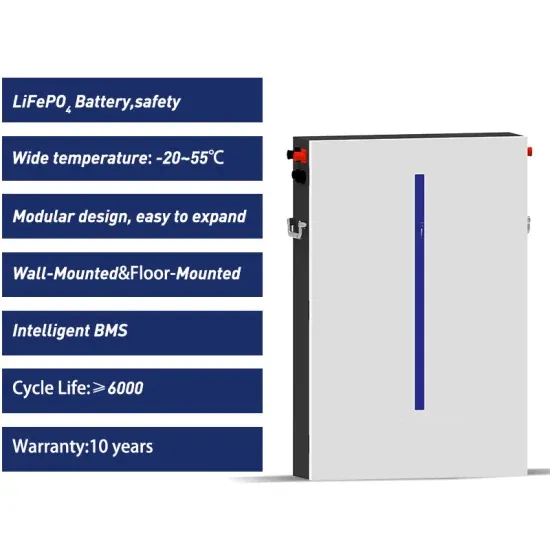

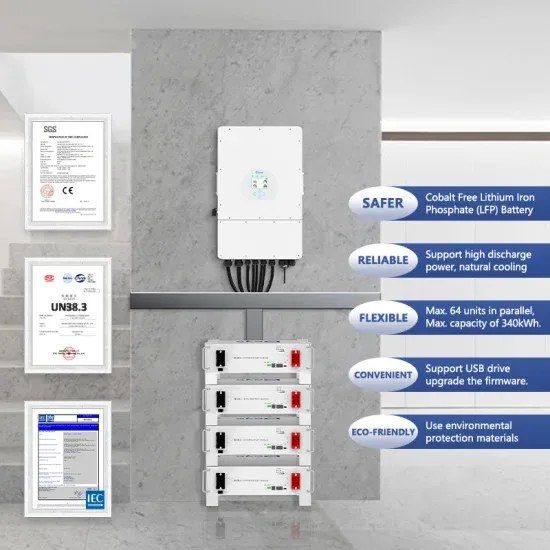

May 9, 2025 · Modular battery pack/cabinet design: build scalable modules and battery cabinets through standardized size battery cells (such as 280Ah, 314Ah batteries), supporting flexible

Understanding Lithim Battery Pack Enclosure Design for

May 7, 2025 · What''s a Lithium Battery Pack and Its Casing? A typical Li-ion battery pack consists of: • The Enclosure: Usually split into an upper cover and a lower case (or tray). • Li-ion Cells:

Cabinet and rack which one is better for Li-ion

May 15, 2025 · Cabinets offer safety and protection for Li-ion battery packs, while racks provide scalability and flexibility. Choose based on space, cooling, and

Battery Enclosures & Cabinets

Battery enclosures and cabinets are a safe way to store batteries and to protect them from the elements as well as providiing a line of defense against theft.

Air cooling and heat dissipation performance of multi-layer battery

For multi-layer battery cabinets, experiments were first established to verify the flow field inside the cabinet, ensuring the accuracy of simulation results. Then, the effects of different air supply

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

What''s Inside a Battery? How Does It Work?

Apr 9, 2025 · Explore what''s inside a battery, how it works, and why it matters. Learn about battery parts, safety, and recycling—all in simple, easy-to

Battery Cabinet

Feb 28, 2025 · Purpose This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Battery Energy Storage

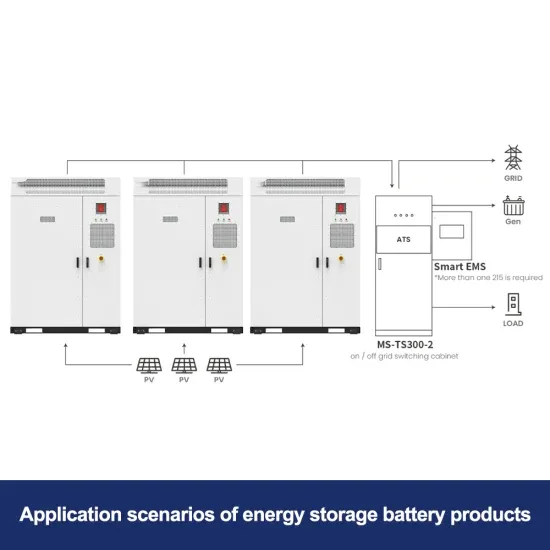

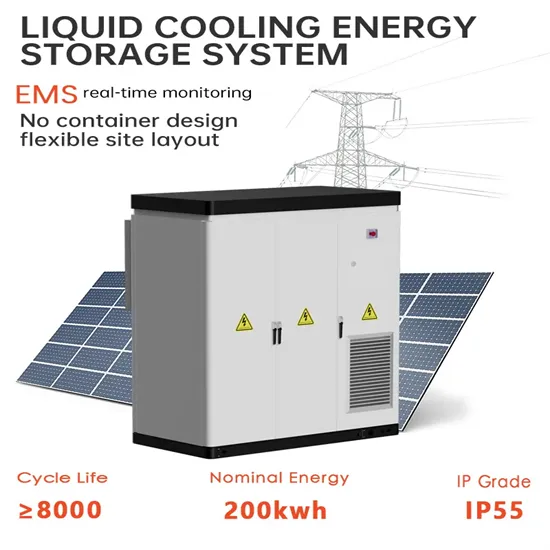

Product development Based on market demand, we have developed two different liquid cooling solutions specially designed for Li-ion Battery Energy Storage Outdoor Cabinets: a side

Lithium battery capacity cabinet principle and maintenance

May 29, 2025 · battery capacity division cabinets achieve consistency in battery cell performance through capacity division management, thereby improving the efficiency and life of the entire

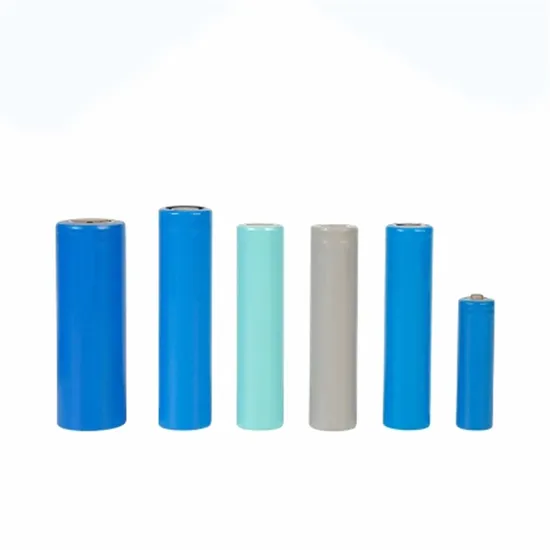

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

6 days ago · Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · directly connect with the battery system with no need for power conversion. Small footprint: for an easy integration inside the battery cabinets and enclosures. Inverter pump and

Battery Cabinet

A maximum of three battery groups in up to six battery cabinets can be deployed inside the smart module. If many batteries are configured, they can be deployed outside the smart module. If

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Choosing the optimal location for installing battery storage cabinets requires a careful balance of several factors. Indoor placement offers greater protection from

836kWh Liquid Cooled Battery Storage Cabinet

AceOn''s Flexible Energy Storage Solution AceOn''s eFlex 836kWh Liquid-Cooling ESS offers a breakthrough in cost efficiency. Thanks to its high energy density

Enclosure Design

A look at the key elements of a battery pack enclosure design. This design will change based on the size and application, but it is still worth approaching this from a high level. One of the first

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · What equipment will be installed inside the enclosure? Only a charger? A battery/rack? A battery/rack and charger? Will other equipment such as spill containment or a

Battery Cabinet

Feb 28, 2025 · The well-ventilated Battery Cabinet provides a housing for batteries that does not allow hydrogen to build up to a dangerous level inside the enclosure. Adequate ventilation

What is Battery Energy Storage? Inside the

Battery Pack A battery pack comprises identical battery modules or individual cells. Configurations may include series, parallel, or a mix to achieve desired

The Importance of Aging Cabinets for Battery Packs

Nov 25, 2024 · Aging cabinets are crucial in the development and testing of battery packs used in electric vehicles, energy storage systems, and other applications. By simulating harsh

Smar tPack-Batter y

Feb 18, 2021 · 6-10kVA UPS battery pack dimension is W443*H131*D525mm. It includes battery connection cables, breaker, terminal, etc, with max. capacity of 16pcs 12V/7Ah or 12V/9Ah

Understanding Lithim Battery Pack Enclosure

May 7, 2025 · Understanding Lithium Battery Pack Enclosure Design for Electric Vehicles and Boats At Bonnen Battery, we specialise in crafting high

Lithium Battery Storage & Charging Cabinets

Fire-resistant secure cabinet, specially developed for storage and charging of lithium-ion batteries, as well as the storage of critical batteries. Risk of fire spreading and accelerating is

Sealing Battery Cabinets for IP67 in EVs: Durability & Safety

Aug 1, 2024 · Sealing Battery Cabinets: Enhance EV safety with IP67 battery cabinet sealing. Explore durable solutions for protecting batteries from environmental hazards.

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

CellBlock Battery Fire Cabinets

CellBlock Battery Storage Cabinets are a superior solution for the safe storage of lithium-ion batteries and devices containing them.

Unpacking the Components of a Battery Energy

Jun 3, 2023 · The BMS is a crucial component of the BESS, tasked with maximizing battery performance, prolonging life, and ensuring safe operation.

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Analysis of Influencing Factors of Battery Cabinet Heat

For the lithium iron phosphate lithium ion battery system cabinet: A numerical model of the battery system is constructed and the temperature field and airflow organization in the battery cabinet

The Ultimate Guide to Battery Charging

Feb 14, 2025 · A lithium battery cabinet is designed to protect batteries from overheating, prevent thermal runaway, and contain any potential fires. These

How to Store Li-ion Batteries for Reliability & Safety

Mar 3, 2025 · Vade Battery''s custom lithium-ion packs feature built-in battery management systems (BMS) that prevent overcharging, but it''s still best practice to disconnect the charger

6 FAQs about [Battery pack inside the battery cabinet]

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

What is a battery enclosure?

A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the battery and all its accessories from the external environment. The enclosures come in different designs and configurations. Enclosure for Battery Battery box plays an integral role in both domestic and industrial applications.

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

How to make a battery box enclosure?

The process involves shaping sheet metal into a battery box enclosure. You can use this method to fabricate any enclosure size or design. Let’s quickly look at the process: Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box.

Industry Information

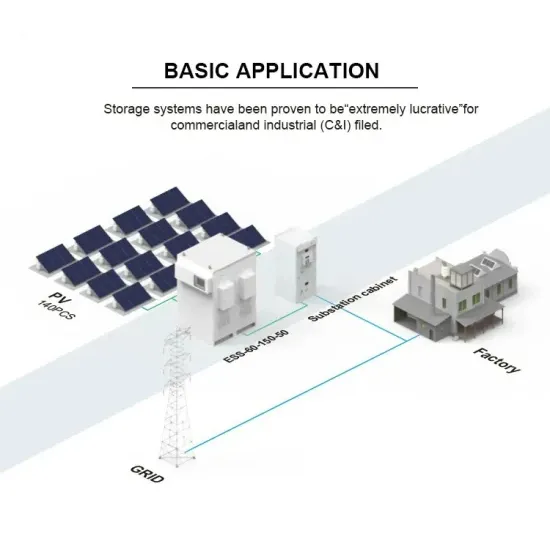

- Photovoltaic outdoor on-site energy is there solar energy

- Latvian commercial wind power generation system

- How much does Finnish energy storage equipment cost

- Botswana energy storage cabinet lithium battery manufacturer

- Luanda battery energy storage equipment

- Black Mountain Energy Storage Machinery and Equipment Procurement

- Kathmandu Energy Storage Power Station

- How much does battery storage cost in Vilnius

- Expected gap between photovoltaic and energy storage

- Will the latest price of photovoltaic modules rise

- Home inverter system in China in Us

- Power of single crystal 60-cell perc module

- Huawei Intelligent Energy Storage Equipment

- The role of inverter cabinet in power

- 200 000 watt solar light

- Battery storage prices in Mogadishu

- North Asia Energy Storage Container

- Industrial Energy Storage Equipment Company

- Ouagadougou Energy Storage System Lithium Battery Factory

- Best wholesale sf6 circuit breaker company

- Podgorica ipm smart inverter price

- Icelandic commercial energy storage cabinet manufacturers

- What are the energy storage power sources that can make money

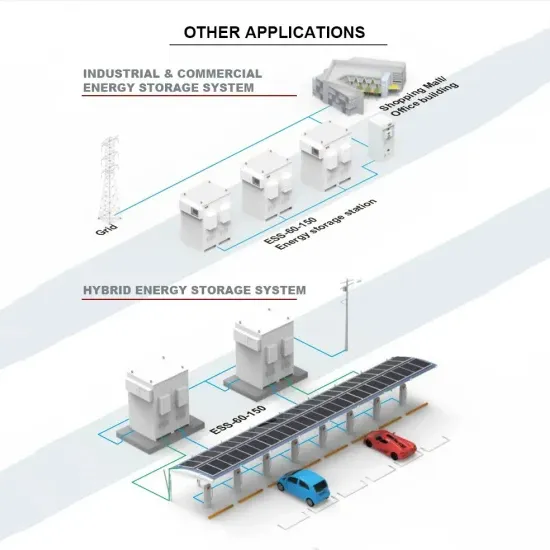

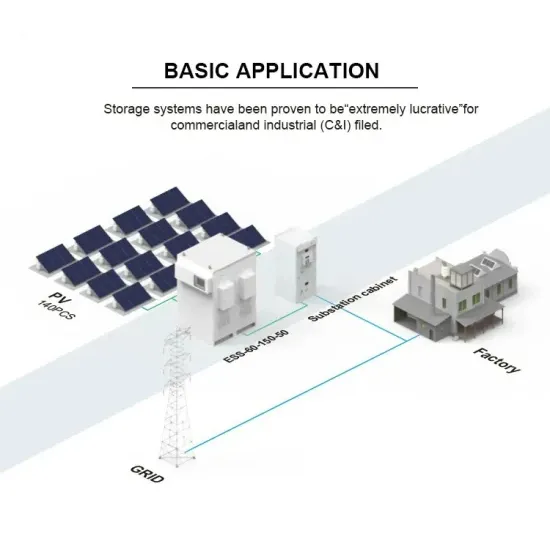

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.