Podgorica Mobile phone lithium battery crushing and

As a major manufacturer of Podgorica Mobile phone lithium battery crushing and recycling equipment company products in the power lithium battery recycling industry, Eastern Europe

Safe production provides high-quality products for Podgorica

Xingmao Machinery Safety Production Promotes Quality, Serving Podgorica lithium battery coil material recycling Negative plate crushing and recovery equipment Customers.

Key Points of Lithium Battery PACK

Jun 27, 2024 · The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective

PRODUCTION PROCESS OF A LITHIUM-ION

Apr 19, 2023 · Cost‐savings in lithium‐ion battery production are crucial for promoting widespread adoption of Battery Electric Vehicles and achieving

From Raw Materials to Finished Product: The

Nov 10, 2024 · From obtaining raw lithium brine and extracting and purifying raw material to manufacturing and testing Li-ion cells to assembling the cells and

How are Lithium-ion Battery Packs Manufactured?

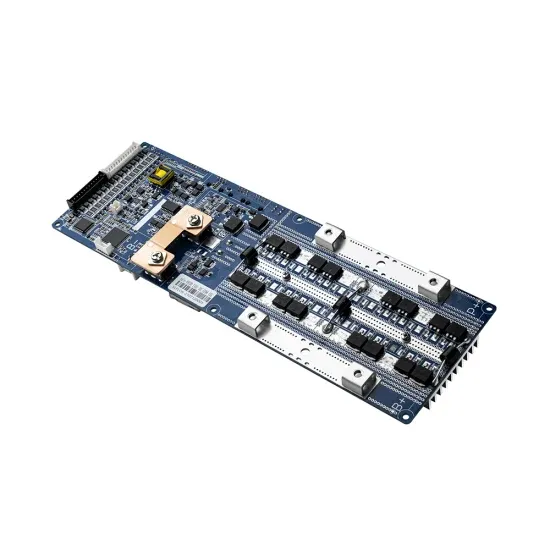

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

BATTERY MODULE AND PACK ASSEMBLY PROCESS

Jan 24, 2022 · Pack production Based on the brochure "Lithium-ion battery cell production process", this brochure schematically illustrates the further processing of the cell into battery

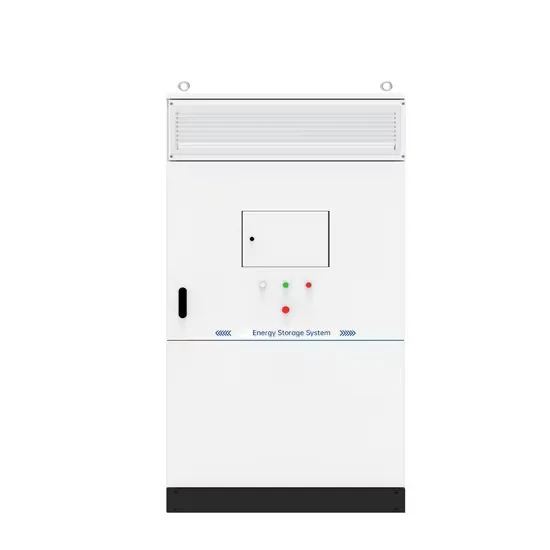

Podgorica energy storage lithium battery

The first rechargeable lithium battery was designed by Whittingham (Exxon) and consisted of a lithium-metal anode, a titanium disulphide (TiS 2) cathode (used to store Li-ions), and an

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

(Infographics #3) Battery Making at a Glance

Jun 14, 2023 · (Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Shop the Best Selection of Podgorica-pack-battery Products

Jul 30, 2025 · Find the perfect Podgorica-pack-battery product at VEVOR. Shop a wide selection of high-quality Podgorica-pack-battery, from accessories to gadgets, and enjoy fast shipping

Lithium Battery Pack Process: Assembly, Management and

The pack process of lithium battery involves many links such as the assembly, management and protection of battery cells, which has an important impact on the performance and safety of

Lithium Ion Battery Manufacturing Process

Aug 17, 2025 · The production of lithium-ion batteries requires extensive procedures. This guide details lithium ion battery manufacturing process.

Battery Pack Manufacturing Process

9 steps of the battery pack manufacturing process: BMS testing, cell sorting, cell mounting, battery module resistance welding, laser welding, shell gluing,

How to Revive a Lithium-Ion Battery: Step-by

Nov 21, 2024 · Safety Measures Before Attempting Battery Revival Before attempting to revive a lithium-ion battery, you need to take safety measures.

Lithium-Ion Battery Manufacturing: Industrial View on

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing

Lithium-ion Battery Manufacturing Front to End

Oct 2, 2022 · Process steps applied in the LIB cell production plant, Batteries Journal MDPI (2022) Bullet-point summary Lithium-ion battery (LIB)

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Podgorica Smart Energy Storage Lithium Battery

Are lithium-rich cathode batteries a good choice? In addition, the lithium-rich cathode materials exhibit high CE and EE of approximately 99% and more than 90%, respectively, surpassing

How much is the Podgorica Scrap lithium battery crushing

This Podgorica Scrap lithium battery crushing and recycling equipment product information is valuable,Eastern Europe crushing equipment Lithium battery circuit board recycling product

Current and future lithium-ion battery

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Does this Mobile phone lithium battery crushing and

Follow Lithium battery recycling and cascade utilization equipment regional security service provider Xingmao Machinery Podgorica network promotion sub-station to learn the common

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · Explore how battery cells are connected, modularized, and equipped with BMS in the Battery Pack Manufacturing Process to deliver efficient and reliable energy for multiple

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

6 FAQs about [Podgorica lithium battery pack processing]

What are the production steps in lithium-ion battery cell manufacturing?

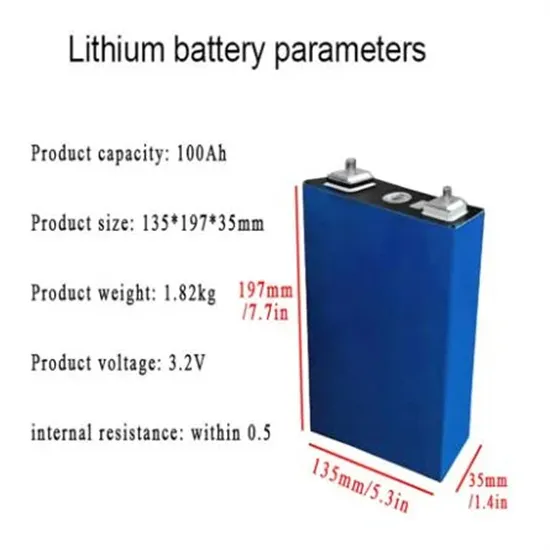

Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and cell finishing (formation) based on prismatic cell format. Electrode manufacturing starts with the reception of the materials in a dry room (environment with controlled humidity, temperature, and pressure).

How are lithium ion battery cells manufactured?

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

How are lithium ion batteries processed?

Conventional processing of a lithium-ion battery cell consists of three steps: (1) electrode manufacturing, (2) cell assembly, and (3) cell finishing (formation) [8, 10]. Although there are different cell formats, such as prismatic, cylindrical and pouch cells, manufacturing of these cells is similar but differs in the cell assembly step.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the transferability of competencies from the production of lithium-ion battery cells is discussed. The publication “Battery Module and Pack Assembly Process” provides a comprehensive process overview for the production of battery modules and packs.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

Industry Information

- Factory price bess electrical in Slovakia

- Photovoltaic inverter can reverse power transmission

- Bahrain Solar System

- Kiribati container energy storage sales

- 1000w solar inverter for sale in Moldova

- Moroccan home sells solar lights

- Battery energy storage balance

- How to install the battery in the communication base station

- Agricultural solar power generation system

- Ngerulmud photovoltaic conductive glass manufacturer

- Lilongwe Industrial Energy Storage Cabinet Manufacturer

- How many energy storage photovoltaic power stations are there in Ukraine

- Sri Lanka Customized Outdoor Power Supply

- Boston lithium battery pack factory

- Baku solar energy storage system manufacturer

- Solar System Life Cycle

- Angola Industrial Park Energy Storage Policy

- Inverter price in Latvia three phase

- UPS battery cabinet installation plan

- Factory price axpert inverter in Los-Angeles

- Solar generator control system

- Honduras photovoltaic power generation 30kw off-grid inverter

- Battery cabinet current is unstable

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

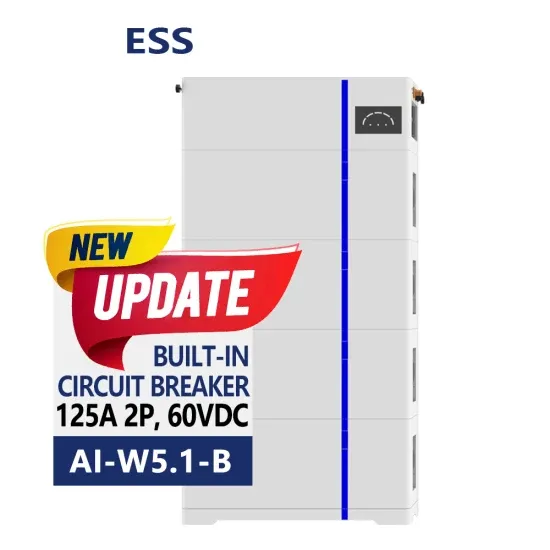

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.