Jtam-A4.dvi

Jan 13, 2024 · In this battery pack, there are six bolts between the box cover and the lug, which are M6 bolts connected to the box cover and the lifting lug, and they are constrained by a

UBPPOWER DIY battery box kits Metal casing

DIY battery box kit, with metal casing and sandblasted surface, featuring built-in JK protection board management system and Anderson charging port.

Material selection of EV battery pack housing

Lithium-ion battery pack with carbon fiber reinforced composite material shell for EV Carbon fiber reinforced composite material is one of the effective ways to solve the development of

Lightweight design and static strength analysis of battery box

Sep 20, 2019 · The battery box was geometrically cleaned, the composite material of the box structure and the foam material of the battery module were defined, and the grid was divided

Strength analysis of the lightweight-designed power battery

Similar to power battery box made of SMC, a design of a battery pack box with maximum bearing capacity was developed with the employment of high anisotropic material - CFRP.

Strength analysis of the lightweight-designed

Jan 1, 2022 · The purpose of the research is to improve the protection level of the battery pack to IP68, to optimize the sheet metal power battery box structure

Design and Optimization for a New Locomotive

Oct 7, 2022 · To solve the disadvantages of the low protection grade, high weight, and high cost of the existing locomotive power battery system, this study

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

ELECTRIC VEHICLE BATTERY PACKS

Depending on material and design requirements, SABIC''s Specialties business can provide a number of materials for electric vehicle battery packs, including

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · A battery cell is the most basic functional unit of a lithium-ion battery. Looking at its structure, each battery cell contains five key

Comparative Material Selection of Battery Pack

This paper discusses the battery pack thermal management components for electric vehicles that are necessary for the batteries to operate effectively in all

EV battery case – definition and material analysis

Jul 1, 2023 · The battery box is mainly composed of an upper cover and a lower case, which is the "skeleton" of the power battery module, and is used to protect the battery PACK against

Understanding Cell and Battery Construction

Aug 20, 2023 · In this article, learn the aspects of cell and battery construction, including electrodes, separators, electrolytes, and the difference between

G2792

Abstract: Battery box lightweighting and stiffness are two important objectives of battery box design and improvement. In order to reduce a battery box''s weight without impairment of

Optimization and Structural Analysis of Automotive

Nov 9, 2024 · Through weight reduction and structural optimization, an innovative power battery pack design scheme is proposed, aiming to achieve a more eficient and lighter electric vehicle

Battery pack material

Aug 15, 2025 · In battery pack material, the high-voltage and low-voltage connections act as the "nerves" of the battery system, effectively outputting

Choosing Battery Enclosure Material: Metal or

Feb 7, 2025 · Explore the differences between metal and plastic battery enclosures for lithium batteries, and learn which material suits your needs best.

Structural Analysis of Battery Pack Box for New Energy

Oct 1, 2022 · The box structure of the power battery pack is an important issue to ensure the safe driving of new energy vehicles, which required relatively better vibration resistance, shock

Power battery structure and principle

Jun 11, 2024 · Figure 1 Position of power battery in the whole vehicle: layout in power battery structure and principle For the whole vehicle to be designed, the

Material selection of EV battery pack housing

The EV battery pack housing is the load-bearing part of the electric vehicle power battery, which is generally installed in the lower part of the car body, and is mainly used to protect the lithium

Optimization Analysis of Power Battery Pack Box

Mar 9, 2023 · This paper uses the finite element model analysis method of the whole vehicle to verify the mechanical properties of the foamed aluminum material through experiments, and

Composition of Battery Pack Material

May 17, 2025 · This article explores the internal structure of a battery pack, its component parts and looking at the several battery pack material used in

Battery Enclosure

Battery enclosure is defined as a container designed for batteries that addresses material selection and heat transfer to ensure safety and longevity, typically utilizing plastic for its

What Type of Foam is Used in Power Battery Cells?

Apr 30, 2025 · It can also be used as a battery sealing ring. Foam materials play a critical role in ensuring the safety, thermal management, and flame-retardant of power battery packs. Why

Identifying Choices in Battery Insulation Material

Larger battery packs power electric vehicles (EVs), smaller lithium-ion or lithium polymer batteries fuel our cellphones and tablets and even ''traditional''

What''s the Purpose of a Battery Box?

Oct 25, 2022 · The caustic nature of batteries and their primary use being exposed to the elements necessitate protection that a battery box can provide.

Lithium Ion Battery Packaging: Soft Pack Design

Apr 8, 2025 · Soft-pack lithium-ion batteries have become a popular power source for electronics, electric vehicles, and energy storage systems. Thanks to their

Understanding Lithim Battery Pack Enclosure

May 7, 2025 · Understanding Lithium Battery Pack Enclosure Design for Electric Vehicles and Boats At Bonnen Battery, we specialise in crafting high

Environmental impact assessment of battery boxes based on

Jan 31, 2024 · By comparing the environmental impacts of the steel battery enclosure with those of lightweight materials such as aluminum alloy and CF-SMC composite material battery

Design Consideration for Battery Box Fabrication

Aug 14, 2025 · They have various applications, including backup battery storage units, exchangeable packs for electric vehicles, battery-powered industrial

Electric car battery construction and housing | Knauf

Mar 14, 2024 · Therefore, manufacturers are looking for new material solutions to produce lighter batteries. Manufacturing a housing for a car battery and materials used The materials used to

Structural Analysis of Battery Pack Box for New

Oct 1, 2022 · The box structure of the power battery pack is an important issue to ensure the safe driving of new energy vehicles, which required relatively better

The material of the battery pack shell

Aluminum alloy is an ideal material for battery pack housing, which is widely used in electric vehicles and energy storage systems because of its light weight, high strength and good heat

Optimization Analysis of Power Battery Pack Box Structure

Mar 10, 2023 · The power battery is the only source of power for battery electric vehicles, and the safety of the battery pack box structure provides an important guarantee for the safe driving of

6 FAQs about [What is the material of the power battery pack box ]

What is a power battery pack box?

The power battery pack box is the core component of the BEV. The power battery pack provides energy for the whole vehicle, and the battery module is protected by the outer casing. The battery pack is generally fixed at the bottom of the car, below the passenger compartment, by means of bolt connections.

What is a battery box?

The battery box is a pure incremental component in new energy vehicles, and the value of a single vehicle is about 3,000 yuan. The battery box is mainly composed of an upper cover and a lower case, which is the “skeleton” of the power battery module, and is used to protect the battery PACK against external impact, dustproof and waterproof.

What is the main structure of a battery pack box?

The main structure of the battery pack box includes the upper-pressure cover, the upper-pressure rod, the lower box body of the battery pack, the inner frame, the lifting lug, the battery module, the single battery, and other structures.

What is a car battery pack housing made of?

The traditional car battery pack housing is cast from steel plate, aluminum alloy and other materials, and then the surface is sprayed.

What is a battery pack housing?

The steel battery pack housing is the most primitive power battery pack case material. It is generally welded by cast steel plates. It is characterized by high strength, high rigidity and heavy weight.

What materials are used in battery pack housing?

With the development of energy saving, environmental protection and lightweight of the car, a variety of lightweight material options such as glass fiber reinforced composite materials, SMC sheet materials, and carbon fiber reinforced composite materials have also appeared in battery pack housing materials.

Industry Information

- Oman Flywheel Energy Storage Production Plant

- China circuit breaker amps for sale company

- 45W Solar Water Pump

- What is the pue value of hybrid energy for communication base stations

- Palestine photovoltaic folding container villa wholesale

- Doha off-grid photovoltaic power generation system

- 300wh power station for sale in Bandung

- Purchase 36V Solar PV Panels

- San Salvador 12V Lithium Cylindrical Battery

- Suburban Uninterruptible Power Supply BESS

- Manama foldable photovoltaic panel manufacturer

- Bridgetown Valley Power Energy Storage Equipment

- Lithium battery energy storage cabinet application scenarios

- West Africa Communication Base Station Inverter Project

- Mbabane rear 220V power inverter

- Kingston Energy Storage Project Company

- Tunisia Energy Storage Station Container BESS

- Single phase breaker for sale in Laos

- Huawei Brazil air-cooled energy storage system

- Current specifications of photovoltaic panels

- Togo makes energy storage batteries

- TdHow many users can a base station generally provide communication for

- Seychelles Solar Air Conditioning

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

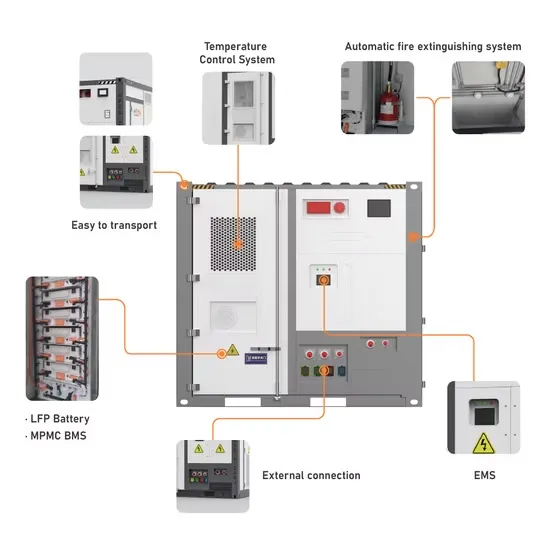

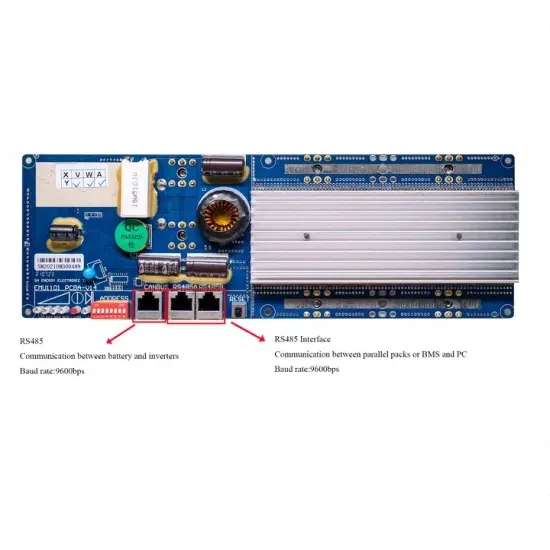

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.