Study on the Fire Suppression Efficiency of Common

Feb 4, 2025 · Lithium battery fires pose a significant threat to life and property. Prompt fire suppression intervention is crucial to suppress the development of such fires. To investigate

Capacity fade characteristics of lithium iron phosphate cell

Sep 1, 2020 · As a key issue of electric vehicles, the capacity fade of lithium iron phosphate battery is closely related to solid electrolyte interphase growth and maximum temperature. In

Lithium Iron Phosphate Superbattery for Mass-Market

Jan 2, 2024 · Remarkable high-temperature stability with 6100 h of cycle life was achieved at 60 °C. With self-heating, the cell can deliver an energy and power density of 90.2 Wh/kg and

Specific Heat Capacity of Lithium Ion Cells

Jan 4, 2022 · The specific heat capacity of lithium ion cells is a key parameter to understanding the thermal behaviour. From literature we see the specific heat

Thermal runaway and fire behaviors of lithium iron phosphate battery

Oct 1, 2020 · Larsson et al. [24] conducted fire tests to estimate gas emissions of commercial lithium iron phosphate cells (LiFePO4) exposed to a controlled propane fire. All the

Capacity fade characteristics of lithium iron phosphate cell

Sep 1, 2020 · The electrolyte interphase film growth, relative capacity and temperature change of lithium iron phosphate battery are obtained under various operating conditions during the

Life cycle testing and reliability analysis of prismatic

May 17, 2024 · Zhang et al. (Zhang, Xu, and Jow 2003) demonstrated that the charge-transfer performance of lithium-ion batteries at low temperatures can be improved. If the ambient

Comparing the Cold-Cranking Performance of Lead-Acid

Feb 21, 2023 · Six test cells, two lead–acid batteries (LABs), and four lithium iron phosphate (LFP) batteries have been tested regarding their capacity at various temperatures (25 °C, 0

Thermal accumulation characteristics of lithium iron phosphate

At present, scholars have carried out extensive research on the heat production characteristics of lithium batteries under different discharge multipliers. Literature [9] studied the heat generation

Thermally modulated lithium iron phosphate batteries for mass

Jan 18, 2021 · The pursuit of energy density has driven electric vehicle (EV) batteries from using lithium iron phosphate (LFP) cathodes in early days to ternary layered oxides increasingly rich

Analysis of Lithium Iron Phosphate Battery Damage | Atlantis

Charge-discharge experiments of lithium iron phosphate (LiFePO4) battery packs have been performed on an experimental platform, and electrochemical properties and damage

Reliability assessment and failure analysis of lithium iron phosphate

Feb 20, 2014 · In this paper, we present experimental data on the resistance, capacity, and life cycle of lithium iron phosphate batteries collected by conducting full life cycle testing on one

Analysis of the Charging and Discharging

Jul 5, 2021 · In these types of devices, lithium-ion batteries are commonly used nowadays, and in particular their variety—lithium iron phosphate

Investigate the changes of aged lithium iron

Dec 20, 2024 · During the usage of lithium-ion batteries, various components undergo different degrees of aging, resulting in phenomena such as increased

Enhancing low temperature properties through nano-structured lithium

Jan 5, 2025 · The mechanism of low-temperature charge and discharge process is explored to achieve the discharge ability of lithium iron phosphate battery at −60℃, which plays an

BU-205: Types of Lithium-ion

Dec 8, 2023 · Become familiar with the many different types of lithium-ion batteries: Lithium Cobalt Oxide, Lithium Manganese Oxide, Lithium Iron

Analysis of Lithium Iron Phosphate Battery Damage

Charge-discharge experiments of lithium iron phosphate (LiFePO4) battery packs have been performed on an experimental platform, and electrochemical properties and damage

The Comprehensive Guide to LiFePO4 Voltage

The LiFePO4 Voltage Chart stands as an essential resource for comprehending the charging levels and condition of Lithium Iron Phosphate batteries. This

Lithium Battery Cold Temperature Operation | Fact Sheets

A lithium battery, like all other types of batteries, have reduced performance and service life when operating at temperatures below room temperature. Performance reductions are in the form of

Electro-thermal analysis of Lithium Iron Phosphate battery

Mar 1, 2014 · Lithium-ion batteries provide an attractive solution for EVs due to its high power and energy density, however, thermal issues in Li-ion batteries have to be addressed to make

Optimum Selection of Lithium Iron Phosphate

Jan 1, 2025 · This paper presents a systematic approach to selecting lithium iron phosphate (LFP) battery cells for electric vehicle (EV) applications,

Enhancing low temperature properties through nano-structured lithium

Jan 5, 2025 · Abstract Lithium iron phosphate battery works harder and lose the vast majority of energy and capacity at the temperature below −20 ℃, because electron transfer resistance

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Estimating the tipping point for lithium iron phosphate batteries

Jan 1, 2025 · Our model – which considers tradeoffs between battery capacity and weight – enumerates a range ''tipping point'' of 373.52 miles, beyond which NMC batteries consistently

How to charge Lithium Iron Phosphate lithium

Apr 17, 2023 · How to charge Lithium Iron Phosphate lithium ion battery packs including packs with high current and High Capacity.

How Do Lithium Iron Phosphate Battery Packs Work and

Lithium iron phosphate (LiFePO4) battery packs are a type of rechargeable battery known for their safety, longevity, and environmental friendliness. They operate by transferring lithium ions

Lithium iron Phosphate Battery Specification

Feb 26, 2024 · 3. Performance and Test Conditions 3.1 Standard Test Conditions Test should be conducted with new batteries within one week after shipment from our factory and the batteries

What Are LiFePO4 Lithium Iron Phosphate Battery Packs and

Feb 26, 2025 · LiFePO4 (lithium iron phosphate) battery packs are rechargeable energy storage systems using lithium-ion chemistry with a phosphate-based cathode. They offer high thermal

Characterization of Multiplicative Discharge of Lithium Iron Phosphate

Oct 13, 2024 · As one of the core components of the energy storage system, it is crucial to explore the performance of lithium iron phosphate batteries under different operati

Complete Guide to LiFePO4 Battery Charging

Jul 23, 2025 · The positive electrode material of lithium iron phosphate batteries is generally called lithium iron phosphate, and the negative electrode material is

LiFePO4 Battery Discharge and charge Curve

4 days ago · 24V lithium iron phosphate batteries are another popular option for solar power projects. You can either buy an off-the-shelf 24V battery or pick

DIY LiFePO4 Battery Pack: Step-by-Step Guide (2025 Update

Apr 18, 2025 · How to Build a LiFePO4 Battery Pack: DIY Guide with Expert Tips (2025) Why Build a LiFePO4 Battery Pack? LiFePO4 (Lithium Iron Phosphate) batteries dominate

6 FAQs about [Lithium iron phosphate battery pack capacity at 0 degrees]

What temperature can a lithium phosphate battery be used at?

Author to whom correspondence should be addressed. Six test cells, two lead–acid batteries (LABs), and four lithium iron phosphate (LFP) batteries have been tested regarding their capacity at various temperatures (25 °C, 0 °C, and −18 °C) and regarding their cold crank capability at low temperatures (0 °C, −10 °C, −18 °C, and −30 °C).

Can lithium iron phosphate batteries discharge at 60°C?

Compared with the research results of lithium iron phosphate in the past 3 years, it is found that this technological innovation has obvious advantages, lithium iron phosphate batteries can discharge at −60℃, and low temperature discharge capacity is higher. Table 5. Comparison of low temperature discharge capacity of LiFePO 4 / C samples.

What is the capacity retention rate of lithium iron phosphate batteries?

After 150 cycles of testing, its capacity retention rate is as high as 99.7 %, and it can still maintain 81.1 % of the room temperature capacity at low temperatures, and it is effective and universal. This new strategy improves the low-temperature performance and application range of lithium iron phosphate batteries.

Why is lithium iron phosphate a bad battery?

Lithium iron phosphate battery works harder and lose the vast majority of energy and capacity at the temperature below −20 ℃, because electron transfer resistance (Rct) increases at low-temperature lithium-ion batteries, and lithium-ion batteries can hardly charge at −10℃. Serious performance attenuation limits its application in cold environments.

What are lithium iron phosphate batteries?

1. Introduction Lithium iron phosphate batteries (LIBs) have been widely used for their long service life, high energy density, environmental friendliness, and effective integration of renewable resources , , , , , , , .

Does lithium iron phosphate affect low-temperature discharge performance?

In this paper, according to the dynamic characteristics of charge and discharge of lithium-ion battery system, the structure of lithium iron phosphate is adjusted, and the nano-size has a significant impact on the low-temperature discharge performance.

Industry Information

- Photovoltaic off-grid power generation system configuration

- Uninterruptible power supply low voltage

- 5kw on grid inverter in China in Kyrgyzstan

- Negative 48V to 220V inverter

- Ulaanbaatar BESS outdoor power supply price

- Solar panel charging and discharging system

- A40 battery cabinet support specifications

- Solar power solutions factory in Finland

- Centralized energy storage project in northern Mauritania

- Liquid Cooling Energy Storage Cabinet Assembly Production Line

- Latvian mobile power station generator manufacturer

- Andorra City DC uninterruptible power supply recommendation

- 24v high frequency inverter efficiency

- The charging voltage of photovoltaic panels is low

- Ghana shopping mall photovoltaic panel manufacturer

- West Asia container folding photovoltaic panels

- Dubai household energy storage lithium battery manufacturer

- What tiles are needed for photovoltaic roofs

- Al jameel switchgear for sale in Czech-Republic

- Managua Energy Storage System Peak Shaving and Valley Filling Project

- Brands of photovoltaic glass in Mexico

- New high-power photovoltaic panel manufacturers

- How long does it take to charge a lithium outdoor power bank in Buenos Aires

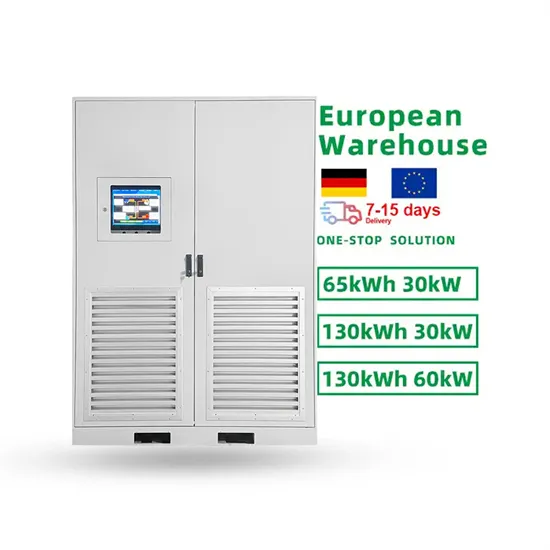

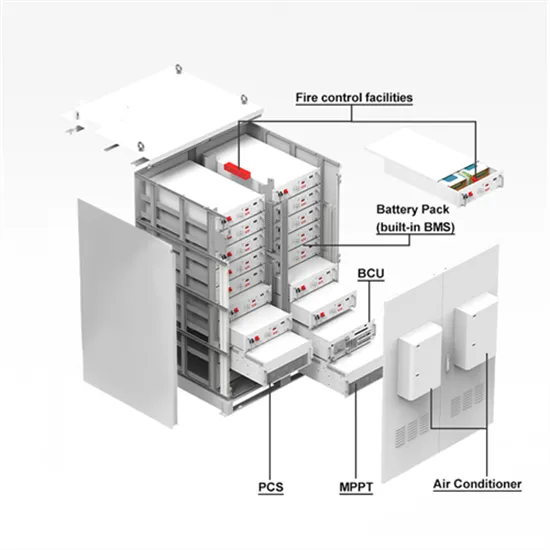

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.