100Pcs 18650 Lithium Battery Holder, Plastic

Jul 29, 2021 · Battery holder has a card slot on the edge, you can freely combine the battery. Battery pack bracket supports the battery, which makes the

100pcs 18650 Lithium Battery Cell Holder, Plastic

Apr 23, 2021 · 100pcs 18650 Lithium Battery Cell Holder, Plastic Li-ion Battery Pack Bracket Safety Spacer Radiating Shell Storage Bracket Cylindrical Cell

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

EV-Battery-Packaging | Covestro

EV Battery Platforms: from modular to cell-to-pack architectures The design of lithium-ion battery packs typically encompasses cylindrical, prismatic, or

Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

100 Pcs 18650 Lithium Battery Cell Holder,

100 Pcs 18650 Lithium Battery Cell Holder, Battery Storage Box Cell Spacer Bracket Stand Plastic Battery Pack Bracket Cylindrical Cell Battery Stand for

The Science of Cylindrical Cells: Understanding

Oct 11, 2024 · Cylindrical cells have become an integral part of the energy storage industry, with a promising future ahead. These cells, also known as

Modelling of a Cylindrical Battery Mechanical

Sep 9, 2024 · The specific focus on the mechanical behavior of the homogenization of cylindrical Li-ion batteries using a plastic material model

100Pcs 18650 Lithium Battery Holder Kit,

Oct 30, 2024 · About this item Strong and Secure Battery Pack Assembly: Designed for 18650 lithium batteries, these cylindrical brackets securely hold

Cylindrical vs. Prismatic vs. Li-Po Battery: Key Differences

Feb 29, 2024 · There are three main mainstream lithium battery packaging forms, namely cylindrical, prismatic, and lithium polymer. The three shapes of lithium batteries will eventually

Analysis of cylindrical lithium battery advantages

Feb 6, 2023 · Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery.

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · For the modeling of cylindrical lithium-ion batteries, detailed structural models [7] including cathode material, cathode material, diaphragms, and shells can more accurately

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · The type of battery cell (pouch, prismatic, or cylindrical) is the foundation of your battery''s performance, reliability, and safety. Whether you''re powering an RV, marine vessel,

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · In the new energy era, lithium batteries are the core power and energy storage unit, and their importance is self-evident. Among the many characteristics of lithium batteries,

Unlocking the significant role of shell material for lithium-ion

Dec 15, 2018 · The cylindrical lithium-ion battery has been widely used in 3C, xEVs, and energy storage applications, as the first-generation commercial lithium-ion cells. Among three types of

Cylindrical Lithium Technologies

6 days ago · Safely harness pure lithium energy with Panasonic Cylindrical Lithium. A lightweight, high-energy-density battery optimized for stable

The production of lithium-ion cells

Jan 25, 2023 · Cylindrical lithium cells As can easily be inferred, cylindrical cells are cylinder-shaped, are the most commonly used and were among the first to

China manufacturer specialists in Lithium Battery

Discover high-quality Lithium Battery solutions and empty plastic battery cases from a leading China manufacturer. Our specialists provide reliable and

Finite Element Analysis of the Mechanical

Jul 9, 2024 · The plastic properties for the jellyroll of lithium-ion batteries showed different behavior in tension and compression, showing the yield strength in

Cylindrical Lithium Battery Cap: Safety

Cylindrical lithium battery caps are popular for their efficiency, lifespan, and compact size. But their safety hinges on a crucial component: the cap

Sinopoly Battery Catalog Page Version

Sep 10, 2024 · Its battery products are widely used in transportation, power, industrial, communication and other fields. Aluminum Prismatic LFP Cell Plastic Prismatic LFP Cell

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · Among the many characteristics of lithium batteries, the external form of packaging shape actually contains complex technical considerations and process logic. The

The differences between lithium cylindrical and

Apr 18, 2025 · The differences between lithium cylindrical and prismatic cells We all know lithium batteries have three ways of package: lithium cylindrical,

Future of Lithium-Ion Batteries: Cylindrical,

Apr 18, 2025 · There are three primary forms of lithium-ion battery packaging: cylindrical, square, and soft pouch. Each packaging structure has distinct

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

100/300Pcs 18650 Lithium Battery Holder, Plastic

100/300Pcs 18650 Lithium Battery Holder, Plastic Battery Bracket Cylindrical Cell Battery Stand Cell Spacer for DIY Fixed Batte 4.6 355 Reviews ౹ 1,000+ sold

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Cylindrical Lithium-ion Batteries have been used in many electronic devices. The electrochemical cell of the batteries consists of a layer of positive electrode, a layer of negative

Three Types of Lithium Battery Packaging and

As lithium batteries continue to dominate consumer electronics, electric vehicles (EVs), and energy storage systems, their packaging design plays a crucial

Different types of battery casings

Feb 6, 2025 · The Critical Role of Battery Casings and Battery Containers Battery casings and battery containers are essential for safeguarding internal battery components from physical

Choosing Battery Enclosure Material: Metal or

Feb 7, 2025 · Explore the differences between metal and plastic battery enclosures for lithium batteries, and learn which material suits your needs best.

Amazon : Lithium Ion Battery Holder

100 Pcs 18650 Lithium Battery Cell Holder, Battery Storage Box Cell Spacer Bracket Stand Plastic Battery Pack Bracket Cylindrical Cell Battery Stand for DIY Fixed 18650 Battery

Plastic Prismatic Lithium Battery Cell vs. Traditional Cylindrical

Jul 3, 2025 · When comparing different types of lithium battery cells, the choice often boils down to specific application needs and performance characteristics. Understanding the distinctions

Understanding the Differences Between

Mar 18, 2025 · Compare prismatic, pouch, and cylindrical lithium battery cells. Learn how design, energy density, and durability affect performance and

6 FAQs about [Cylindrical lithium battery plastic]

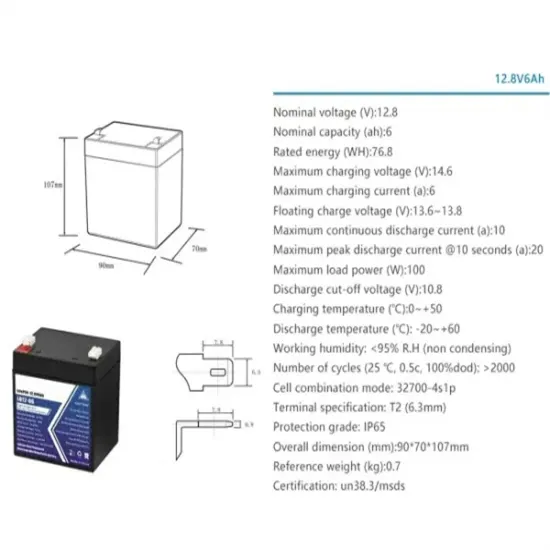

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

What are the different types of lithium battery packaging?

There are three main mainstream lithium battery packaging forms, namely cylindrical, prismatic, and lithium polymer. The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination.

What is a lithium polymer battery?

Lithium polymer batteries are currently the least used battery form in electric vehicles. But in fact, we are not unfamiliar with it. Most of the batteries in mobile phones are lithium polymer batteries. The biggest difference between lithium polymer, cylindrical, and prismatic batteries is that their outer casing is made of aluminum-plastic film.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

What are the different types of lithium batteries?

The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination. Different packaging structures mean different characteristics, so what are their differences? Part 1. What’s the cylindrical lithium battery?

What is a cylindrical battery?

At present, cylindrical batteries are mainly steel-cased cylindrical lithium iron phosphate. This cylindrical battery has high capacity, high output voltage, and good charge and discharge cycle performance. Lithium iron phosphate belts are promised to be used in solar lamps, lawn lamps, backup energy sources, power tools, toy models, etc.

Industry Information

- Honduras light-transmitting series photovoltaic power generation glass wholesale

- Paris Super Farad Capacitor

- El Salvador regular inverter manufacturer

- Tunisia Bidirectional Portable Energy Storage Project

- Factory price 7 5 kw inverter in Panama

- Advantages of independent energy storage power stations

- Hot sale quad circuit breaker factory Seller

- Distributed energy storage power stations are feasible

- Dual circuit breaker in China in Uae

- Communication base station inverter grid-connected special tower

- Appearance design outdoor energy storage power supply

- Tbilisi Signal Base Station Solar Panels

- Malawi Energy Storage Container Fire Fighting System

- Lesotho 60v to 220v inverter

- Nanya Industrial and Commercial Energy Storage Cabinet

- Energy storage equipment energy storage cabinet

- Skopje Communication Base Station Inverter 215KWh

- 220v small water pump modified into solar water pumping

- Does Cote d Ivoire have a 5G base station with power signal

- 4 2 kw solar inverter factory in Nairobi

- Energy storage liquid cooling unit 50kw

- Wind and solar energy air conditioning

- Wholesale 2000 amp switchgear in Bhutan

Commercial & Industrial Solar Storage Market Growth

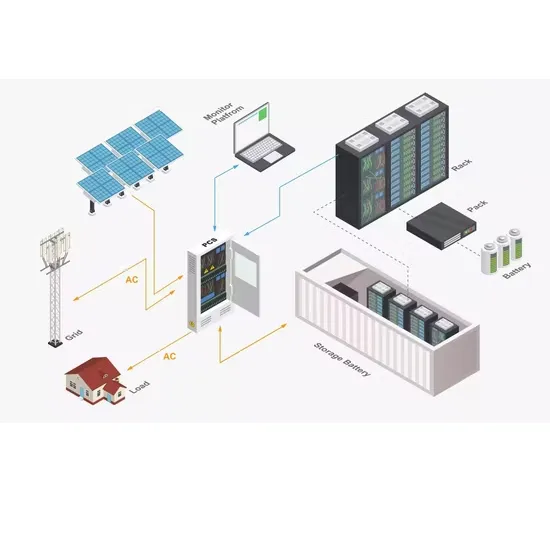

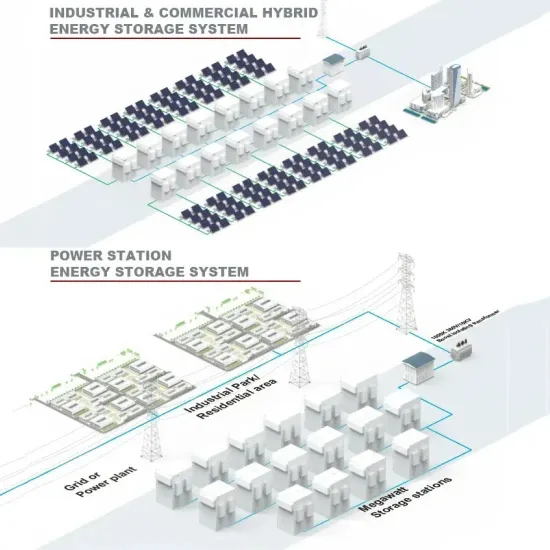

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

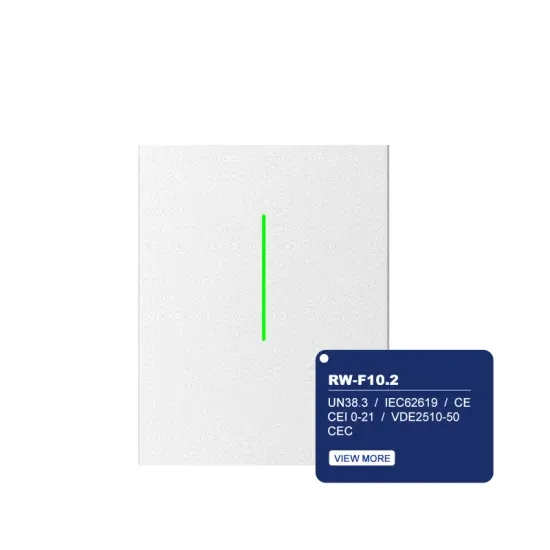

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.