Which is better single crystal photovoltaic panel or

Oct 19, 2022 · Monocrystalline panels are made of single-crystal silicon, which is melted into bars, cut into wafers, and treated with anti-reflective coating that improves its efficiency and

A Comprehensive Guide to Solar Panel

4 days ago · The solar energy industry has experienced significant advancements, resulting in a variety of solar panel technologies tailored to

FORMATION AND APPLICATIONS OF SINGLE

Dec 22, 2017 · Abstract and Figures The single crystal is essentially a single giant grain in which the arrangement of molecules exhibits strict order.

WHO INVENTED SOLAR PANELS?

Photovoltaic solar panel varieties Monocrystalline panels are manufactured from a single crystal of pure silicon. This manufacturing process results in a very uniform material that is characterised

Which is better single crystal photovoltaic panel or

Oct 19, 2022 · Shingled solar panel components are made by slicing traditional battery cells (single crystal, polycrystalline, Sunpower, etc.) and connecting each small piece in a forward

Types of Solar Panels in Australia: A

Nov 7, 2022 · In the past few years, solar energy panel technology has advanced to a new level, and with new technology comes unique inventiveness.

Why Monocrystalline Solar Panels Outperform

Feb 25, 2025 · While monocrystalline cells are crafted from a single, pure silicon crystal and typically achieve higher efficiency ratings of 15-22%,

Mono PERC vs Monocrystalline Solar Panels: An

Feb 7, 2024 · Discover the key differences between Mono PERC vs Monocrystalline solar panels, including efficiency comparisons, cost

Multicrystalline Silicon

Multi-crystalline silicon is defined as a material composed of many smaller silicon grains with different crystal orientations, typically produced by cutting multi-crystalline ingots formed from

Single crystal and multi-crystalline solar panels are not

aAs-based single-junction solar cells exhibit the maximum stability. Similarly, Fig. 1 b shows the certified efficiency chart for single and polycrystalline single-junction solar cells, indicating that

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Single‐Crystal Perovskite for Solar Cell Applications

Sep 20, 2024 · The advent of organic–inorganic hybrid metal halide perovskites has revolutionized photovoltaics, with polycrystalline thin films reaching over

Single and multi-crystalline solar photovoltaic panels

Being the most used PV technology, Single-crystalline silicon (sc-Si) solar cells normally have a high laboratory efficiency from 25% to 27%, a commercial efficiency from 16% to 22%, and a

Shingled vs. Half-Cut Panels: Similarities

Jun 14, 2024 · Compare shingled and half-cut solar panels, exploring their similarities & differences in composition, performance durability & applications.

Review of life cycle analyses and embodied energy

May 1, 2016 · This paper attempts to summarise the latest developments of two prominent crystalline, i.e. single crystalline (sc-) and multi crystalline (mc-) silicon PV systems with

Review of life cycle analyses and embodied energy

May 1, 2016 · While photovoltaic (PV) technology is considered a renewable energy source, it nonetheless has a degree of environmental impact. In order to completely capture the net

A Comprehensive Guide to Solar Panel

4 days ago · There are three main aspects to consider when understanding solar panels: cell types (e.g. monocrystalline, polycrystalline, PERC, HJT), cell

How to distinguish single and multi-crystalline solar energy

Mar 19, 2024 · To differentiate between single-crystalline and multi-crystalline solar panels, several key characteristics must be examined. 1. Material Structure, 2. Efficiency, 3. Cost

Single crystal Perovskite-Based solar Cells: Growth,

Jun 15, 2023 · Therefore, single-crystal perovskite solar cells (SC-PSCs) have recently received significant attention in the fabrication of highly efficient and stable PSCs owing to their

Monocrystalline Solar Panels: Advantages and

8 Good Reasons Why Monocrystalline Solar Panels are the Industry Standard Monocrystalline photovoltaic electric solar energy panels have been the go-to

Shingled Solar Panels vs Monocrystalline | What Apart Them

Jul 27, 2023 · In short, shingled solar panels are made of many small, overlapping solar cells and tend to be more efficient but also more expensive than traditional monocrystalline panels.

Perovskite Single-Crystal Solar Cells: Going

Jan 25, 2021 · Most efficient perovskite solar cells are based on polycrystalline thin films; however, substantial structural disorder and defective grain

Polycrystalline Solar Panel Specifications

Nov 17, 2023 · Polycrystalline Solar Panel Specifications: More environmentally friendly, less heat-tolerant, greater temperature coefficient, and the like.

Whc Wholesale Waterproof Monocrystalline Shingled 250W

Feb 12, 2025 · Whc Wholesale Waterproof Monocrystalline Shingled 250W-550W 182 Mbb Solar Panels, Find Details and Price about Solar Panel Power Bank from Whc Wholesale

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The silicon energy bandgap determines the ultimate efficiency of PV cells made from c-Si; this value is 29.4%. As already explained in Section 8.4.2, c-Si solar cells have to be

Monocrystalline vs. Polycrystalline solar panels

Sep 19, 2024 · Polycrystalline or multi crystalline solar panels are solar panels that consist of several crystals of silicon in a single PV cell. Several fragments of silicon are melted together

What is Crystalline Silicon Solar Cell?

Nov 17, 2023 · A crystalline silicon solar cell is a particular kind of solar cell constructed from a wafer of silicon ingots that are either monocrystalline

Multicrystalline Solar Modules for PV Projects

6 days ago · Targray''s portfolio of high-efficiency multicrystalline solar modules is built to provide EPCs, installers, contractors and solar PV developers with

What is Single Crystal Silicon?

Nov 17, 2023 · Silicon wafers, whether single or multi-crystalline, are commonly used to fabricate the vast majority of silicon solar cells. Features of single

Introduction To Single Crystal,polycrystalline,and

Apr 7, 2024 · This perfect crystalline structure enables single crystals to have higher crystallinity and crystal integrity. Polycrystalline materials are composed of many grains, which are

Types of PV Panels – Solar Photovoltaic

There are two general types crystalline silicon photovoltaics, monocrystalline and multicrystalline, both of which are wafer-based. Monocrystalline

Multi-crystalline Silicon | UniversityWafer, Inc.

Jan 7, 2025 · For solar cells, it is recommended to buy a bulk ingot rather than a single-crystal silicon one. A single-crystal silicon is a single-crystal structure. It has a homogeneous

6 FAQs about [Single crystal and multi-crystalline shingled solar energy]

What is the difference between monocrystalline and single crystalline solar panels?

While both are reliable and have a mature market, they differ in shape and performance. Monocrystalline, also called single crystalline silicon solar panels, are easily recognizable due to their external dark black color.

What is a monocrystalline solar cell?

1. Monocrystalline Solar Cells (Typically P-Type) Description: Made from a single, pure silicon crystal, recognisable by their dark black colour. Efficiency: High (20% and above). Benefits: They offer high power output, are space-efficient, and have a long lifespan.

What is a shingled solar module?

With the shingled layout, there are fewer gaps between the individual solar cells so more of the sunlight that is incident on the module can be absorbed. Instead of using external connectors to transport the current from one cell to the next, the area of the cell overlap is used as an electrical connector.

Do shingled solar cells generate more electricity?

In addition, shingled solar cells reflect less light, and thus generate more electricity. The adaptation of solar cell production from the conventional approach to shingled solar cells requires some dedicated optimizations, however. In recent years, we have tested and further developed these techniques in a pilot line production at Fraunhofer ISE.

What are the different types of solar panels?

Half-Cut Cell Layout: Reduces resistance and increases efficiency, often used with monocrystalline and PERC cells. Bifacial Solar Panels: Capture sunlight from both sides, typically paired with N-type cells (TOPCon, HJT) to maximise efficiency. Shingled Cell Layout: Higher efficiency and power density, often used with HJT or monocrystalline cells.

What is solar shingling & how does it work?

The technique of laying out solar cells in a module so that their edges overlap like shingles on a house roof is called »shingling« With the shingled layout, there are fewer gaps between the individual solar cells so more of the sunlight that is incident on the module can be absorbed.

Industry Information

- Containerized generators for sale in Zimbabwe

- Quad circuit breaker factory in Cambodia

- Wireless communication base station flywheel energy storage height

- 10 lithium batteries for electric tools

- 5g base station electrical mode

- Marseille rechargeable energy storage battery price

- Cheap China d curve circuit breaker Wholesaler

- Communication base station UPS power supply duration requirements

- Accra Photovoltaic Module Export Company

- N Djamena energy storage explosion-proof container price

- Address of the power supply plant of Kitga Base Station

- Breaker distribution in China in Iraq

- The life of photovoltaic battery components

- Solar photovoltaic water pump power generation

- Price of energy storage system in Cambodia

- Which departments are involved in the wind and solar complementary service of Samoa s communication base stations

- Port Vila Portable Outdoor Backup Power Plant

- Mogadishu Home Energy Storage System Production Plant

- Rotary energy storage dual power supply

- What are the Danish energy storage container transportation requirements

- Energy storage high voltage box cost

- Main circuit breaker for sale in Gabon

- How does a flywheel store energy

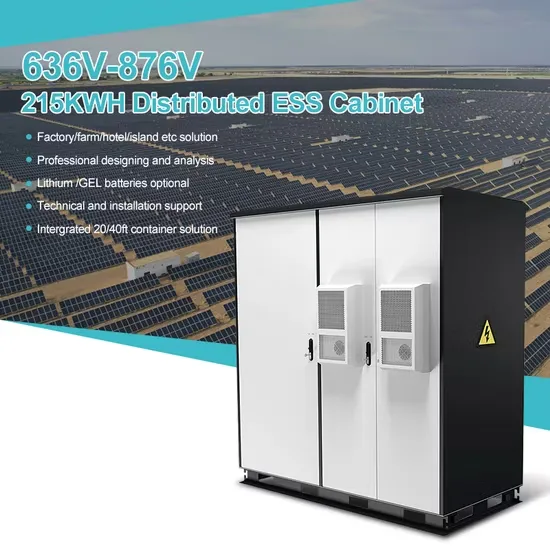

Commercial & Industrial Solar Storage Market Growth

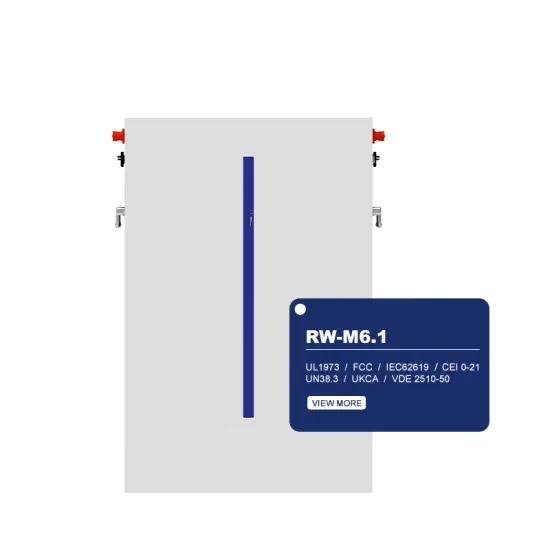

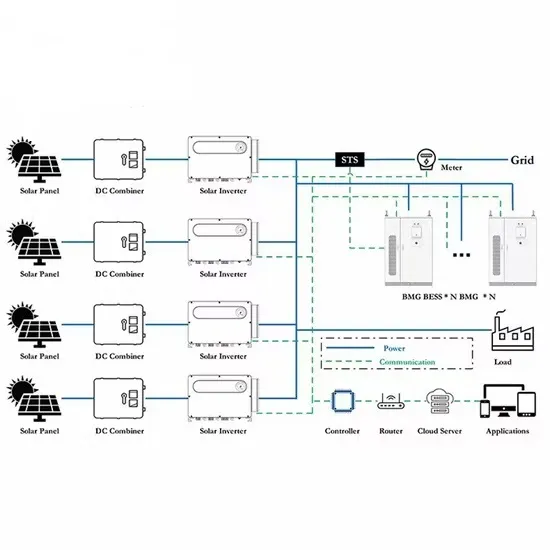

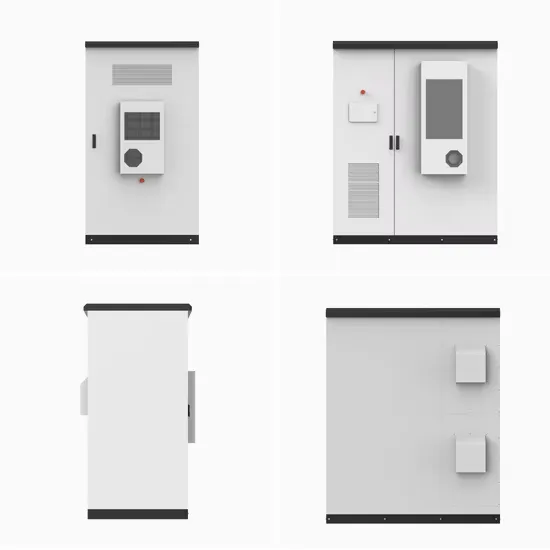

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.