How to Read Solar Inverter Specifications

Nov 17, 2023 · In this comprehensive guide, we''ll explore the critical factors that define the performance and efficiency of solar inverters. From input and output power ratings to

How to Read a PV Spec Sheet: VOC, ISC, STC

1 day ago · Reading a PV spec sheet fast and accurately helps you size strings safely, match inverters, and get realistic energy expectations. This piece

Performance ratio

Feb 3, 2025 · Specifically, the performance ratio is the ratio of the actual and theoretically possible energy outputs. It is largely independent of the orientation of a PV plant and the incident solar

What does the photovoltaic inverter coefficient mean

What does PV or Photovoltaic mean? How solar inverters make PV cells more productive. Inverters are fundamental in solar power systems, since they convert the DC power from

Does Solar Panel Temperature Coefficient Matter?

Apr 20, 2020 · Your solar panel''s temperature coefficient has to do with the influence that the panel''s temperature has on its productivity. In this post, we

How to understand and compare solar panel

Oct 24, 2020 · How to read solar panel specifications. The reason for this is that most people do not understand what each of the terms in the specifications

Performance Ratio Calculation and Activation in the

Apr 4, 2024 · Overview This application note describes how to edit settings in the SolarEdge Monitoring platform to display the Performance Ratio (PR) value. The PR value is a critical

Understanding Solar Performance Ratio (PR)

Performance Ratio (PR), a key solar plant performance indicator, combines technical efficiency with profitability.

Interpreting inverter datasheet and main parameters | AE 868

As power is processed and converted from one shape to another, the solar inverters are expected to perform these tasks with the highest possible efficiency. This is because we wish to deliver

Key Inverter Parameter: Maximum PV Input Voltage

Aug 28, 2024 · The maximum PV input voltage of an inverter is a critical parameter that needs careful consideration during the design and installation of a PV system. Understanding and

Solar String Sizing for Installers & Mistakes to

Jul 18, 2025 · Solar string sizing is key to efficient solar PV production, happy solar inverters, and a durable, high-performing system.

Key Parameters of Solar Panel Data Sheets

Dec 19, 2024 · When selecting a solar panel, understanding the datasheet is vital to selecting the right product for your energy needs. A solar panel data sheet provides technical specifications

Measuring the temperature coefficient of a PV

Jan 8, 2024 · This article is a basic introduction to the temperature coefficient of a solar module, its significance and calculation. Before explaining the

Types of Inverter Efficiency Peak CEC and Euro

Feb 11, 2014 · Solar inverter peak efficiency is a measure of your inverter''s efficiency at a specific level of input power (watts). In this efficiency curve,

The Highs and Lows of Photovoltaic System

Jul 23, 2012 · The power electronics components of a photovoltaic (PV) system, such as grid-direct inverters, have maximum and minimum voltage inputs;

Project design > Results > Performance Ratio PR

Nov 7, 2024 · The PR includes the optical losses (Shadings, IAM, soiling), the array losses (PV conversion, aging, module quality, mismatch, wiring, etc) and the system losses (inverter

What is Voc in Solar Panels?

Sep 24, 2023 · Understanding Voc (Voltage Open Circuit) of a solar panel is critical to avoid damage and maximize power for your DIY solar project.

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · When the input current requirement is met, the PV system achieves its highest efficiency when operating at the rated voltage. If the PV

Solar PV Terms & Definitions in the Industry | Symtech Solar

Dec 14, 2018 · Solar Power: Commonly used technical terms This solar glossary contains definitions and technical terms related to solar power and photovoltaic (PV) technologies and

Photovoltaic Inverters: Key Parameters and

Feb 22, 2024 · Photovoltaic inverter refers to a circuit that completes the inverter function or a device that implements the inverter process. Power board: The

Understanding Solar Photovoltaic System Performance

Feb 17, 2022 · This report presents a performance analysis of 75 solar photovoltaic (PV) systems installed at federal sites, conducted by the Federal Energy Management Program (FEMP) with

Problems with the calculation of

Jul 31, 2023 · When performing the simulation with PVSYST, numerous factors and parameters must be considered, including meteorological data (solar

What Is Maximum System Voltage in Solar

This is crucial when connecting an inverter or controller to the array. Calculating maximum system voltage involves factors like Standard Test Conditions (STC)

Name _______________________ Class

Feb 11, 2020 · For each individual PV system, engineers must use specific equipment, such as inverters, to ensure that the system runs at maximum efficiency. Different inverters are rated

Understanding DC/AC Ratio – HelioScope

Modules produce, inverters process The inverter has the sole purpose of converting the electricity produced by the PV array from DC to AC so that the

Solar Panel Temperature Coefficient Explained

Mar 31, 2024 · Find out how the solar panel temperature coefficient impacts your solar efficiency. Learn how to maintain panels for optimal performance in any

Calculating Max PV Voltage is Not Scary

Jan 22, 2015 · For example: Record-low temperature: -10ºC Temperature coefficient of (VOC): – (0.30) %/ºC Module open circuit voltage (VOC): 39.4 V

Understanding Solar Photovoltaic System Performance

Jan 6, 2022 · Executive Summary This report presents a performance analysis of 75 solar photovoltaic (PV) systems installed at federal sites, conducted by the Federal Energy

Convert Temperature Coefficient

Oct 20, 2024 · Calculate Tvoc from mV/C to %/C It''s important to calculate the lowest and highest Photovoltaic (PV) voltage that is connected to a converting unit, whether that is a string

Understanding DC/AC Ratio – HelioScope

By analyzing the discrete rate of PV devices and PV strings, you can quickly learn about the running status of PV devices and PV strings, facilitating device maintenance. The analysis on

What is Difference Between String And Array In

Nov 17, 2023 · Solar panels connected in succession and connected to a single input on a solar string inverter make up a string. A photovoltaic or PV array is

Harmonics in Photovoltaic Inverters & Mitigation

Dec 22, 2022 · PV Inverter System Configuration: Above g shows the block diagram PV inverter system con guration. PV inverters convert DC to AC power using pulse width modulation

6 FAQs about [What does the photovoltaic inverter coefficient mean ]

How efficient are solar inverters?

As power is processed and converted from one shape to another, the solar inverters are expected to perform these tasks with the highest possible efficiency. This is because we wish to deliver maximum PV generated power to the load or the grid. Typical efficiencies are in the range of more than 95% at rated conditions specified in the datasheet.

What happens if a PV inverter loses power?

In the event that the PV array outputs more energy than the inverter can handle, the inverter will reduce the voltage of the electricity and drop the power output. This loss in power is known as “clipping”. For example, a DC/AC ratio of 1.5 will likely see clipping losses of 2-5%. Not as major as other losses, but still a noticeable effect.

What is inverter conversion efficiency?

Inverters are essential components in a photovoltaic power station, converting the DC power generated by the solar modules into AC power. During this conversion process, a small portion of energy is lost as heat. The ratio of the AC output power to the DC input power is known as the inverter's conversion efficiency. Conversion Efficiency Details

What are the parameters of a PV inverter?

Aside from the operating voltage range, another main parameter is the start-up voltage. It is the lowest acceptable voltage that is needed for the inverter to kick on. Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet.

What is a good DC/AC ratio for a solar inverter?

Because the PV array rarely produces power to its STC capacity, it is common practice and often economically advantageous to size the inverter to be less than the PV array. This ratio of PV to inverter power is measured as the DC/AC ratio. A healthy design will typically have a DC/AC ratio of 1.25.

What is solar inverter peak efficiency?

Efficiency varies for an inverter depending on the input power from your solar panel array, as you can see in the graph below. Solar inverter peak efficiency is a measure of your inverter’s efficiency at a specific level of input power (watts). In this efficiency curve, peak efficiency is about 250W.

Industry Information

- Solar panel power connection system

- Photovoltaic test battery cabinet

- The role of energy storage batteries in solar power stations

- Mobile power cell 21700

- Nauru Photovoltaic Energy Storage Policy

- Solar tile supply price

- Factory Industrial Battery Energy Storage

- 10 square meters solar power generation system

- Outdoor Power Camping Solution

- Minsk Industrial Energy Storage Cabinet Wholesaler Address

- Communication base station brand photovoltaic communication battery

- Inverter default voltage range

- Wholesale suntree dc breaker in Jakarta

- Epcs-10kw-am inverter

- Pakistan EK Photovoltaic Glass

- The new energy storage device has a capacity of approximately 3 3 million kw

- Malabo Energy Storage Battery Wholesale Manufacturer

- San Marino photovoltaic energy storage customization company

- Nuku alofa professional supercapacitor manufacturer

- Equatorial Guinea tops solar photovoltaic panels

- Energy storage photovoltaic module

- Is the inverter effective for home use

- Yamoussoukro No 1 Middle School Solar System

Commercial & Industrial Solar Storage Market Growth

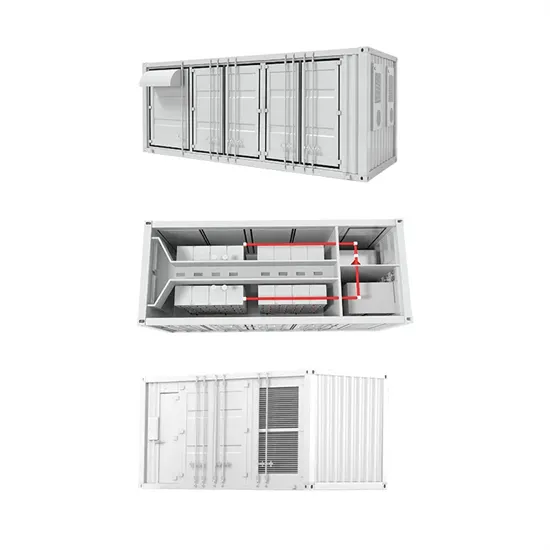

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

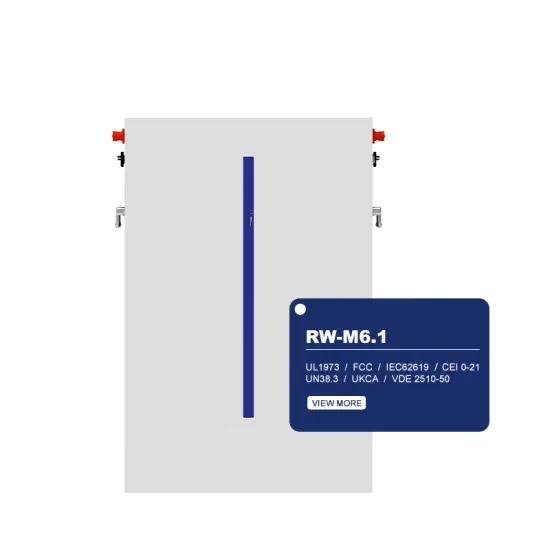

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.