How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

The battery industry has entered a new phase –

Mar 5, 2025 · The Chinese battery ecosystem covers all steps of the supply chain, from mineral mining and refining to the production of battery

International development of WinAck li-ion battery pack

May 18, 2015 · WinAck is gradually from being a single battery pack making machine to delivering the whole battery pack assembly production line to customers. Now, in turn, the whole battery

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Learn how to overcome challenges in lithium-ion battery pack assembly with automation, customization, and advanced process control for

The EV Battery Manufacturing Process: Step by

Jun 5, 2024 · The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · The industrial production of lithium-ion batteries usually involves 50+ individual processes. These processes can be split into three stages:

Battery giant CATL showcases three innovations:

Apr 21, 2025 · Ternary iron/dual-ternary batteries (ternary batteries combined with lithium iron phosphate, or ternary batteries with self-generated ternary

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

How Lithium-ion Batteries Work

Lithium-ion batteries are incredibly popular these days. You can find them in laptops, PDAs, cell phones and iPods. Find out why.

Key Points of Lithium Battery PACK

Jun 27, 2024 · Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Top Lithium Battery Manufacturers in 2025: Who

Mar 12, 2025 · In 2025, a mix of Chinese, South Korean, and Japanese giants dominate the lithium battery landscape. Companies like CATL, BYD, LG

Inside A Gigafactory: What Goes On in Battery

6 days ago · Inside A Gigafactory: What Goes On in Battery Production Powerhouses Here''s how lithium-ion battery gigafactories work and why these

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Explore challenges and solutions in streamlining lithium-ion battery pack processes for efficient, customized, and automated production.

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Three different battery cell types are employed in the automotive field which are small solid cylindrical cells, larger solid prismatic cells, and larger soft pouch or polymer cells

How much CO2 is emitted by manufacturing

Aug 8, 2025 · For illustration, the Tesla Model 3 holds an 80 kWh lithium-ion battery. CO 2 emissions for manufacturing that battery would range between

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · You''ve probably noticed how EVs are becoming more common on the roads. This shift is driving the global power battery industry to expand at

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · 1. Introduction In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution.

The global run to mass production: How the

Dec 18, 2023 · A new Fraunhofer ISI Lithium-Ion battery roadmap focuses on the scaling activities of the battery industry until 2030 and considers the

Lithium-ion cell and battery production processes

May 3, 2018 · Lithium-ion cell production can be divided into three main process steps: forming, aging, and testing. Cell design is the number one criterion when setting up a cell production

Advancing lithium-ion battery manufacturing: novel

Jun 15, 2024 · Lithium-ion batteries (LIBs) have attracted significant attention due to their considerable capacity for delivering effective energy storage. As LIBs are the predominant

Solved Photon Technologies, Inc., a

Question: Photon Technologies, Inc., a manufacturer of batteries for mobile phones, signed a contract with a large electronics manufacturer to produce

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design,

International development of WinAck li-ion battery pack

May 18, 2015 · WinAck is one of the leading companies in lithium-ion battery pack assembly equipment and intelligent automated lithium-ion battery pack production lines. It is also a

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Current and future lithium-ion battery

Apr 23, 2021 · Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share

6 FAQs about [Three-in-one lithium battery pack production]

How are lithium ion battery cells manufactured?

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

What is a lithium ion battery pack?

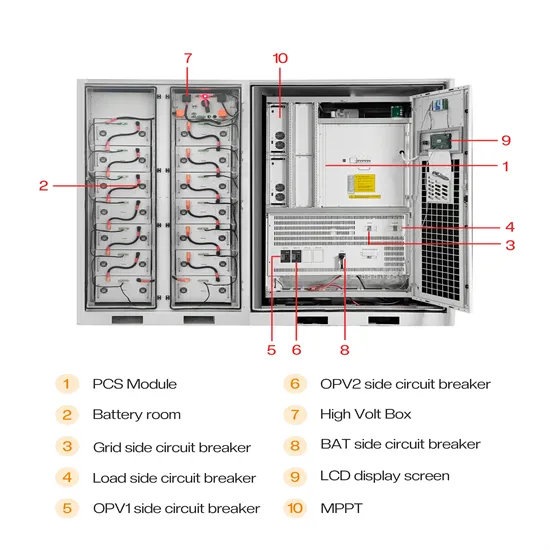

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the packaging and Assembly of lithium-ion battery packs?

The packaging and assembly of lithium-ion battery packs are crucial in the field of energy storage and have a significant impact on applications like electric vehicles and electronics. The pack line process consists of three main phases: production, assembly, and packaging.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the transferability of competencies from the production of lithium-ion battery cells is discussed. The publication “Battery Module and Pack Assembly Process” provides a comprehensive process overview for the production of battery modules and packs.

How to make lithium ion cell?

Lithium-ion cell production can be divided into three main process steps: forming, aging, and testing. Cell design is the number one criterion when setting up a cell production facility. For all designs, four basic requirements must be fulfilled: 1. Each cathode sheet must face an anode sheet with the same or higher capacity.

What are lithium ion battery cells?

Lithium-ion battery cells are a technology that is categorized as a secondary energy storage system, the cells are uncharged after electrolyte filling. Forming is the process step in which the cell is initially charged and essential layers (solid electrolyte interface, SEI) are produced. It is also a quality management control measure.

Industry Information

- Another energy storage power station

- Sukhumi Photovoltaic Curtain Wall

- Sierra Leone outdoor power brand new

- Magadan New Energy Communication Power Supply Battery Cabinet Replacement

- Base station communication circuit board company

- Introduction to communication base station power cabinet

- Lithium battery power station in Iran

- Is the photovoltaic panel roof installation waterproof

- Park solar water pump

- Communication 5g base station contracting

- Preliminary glass production of photovoltaic panels

- Panama Wind Energy Storage System Classification

- Power station energy storage equipment price trend

- Cheap withdrawable circuit breaker company

- Outdoor energy storage cabinet source manufacturer

- Liechtenstein wind power storage system supplier

- Fiji photovoltaic energy storage ratio

- Bahamas Industrial Frequency Off-Grid Inverter Manufacturer

- Bhutan 10GWh energy storage battery project

- Special inverter factory direct sales

- Energy storage power conversion equipment

- New Delhi Photovoltaic Energy Storage 15kw Inverter Company

- What tests do energy storage containers need to undergo

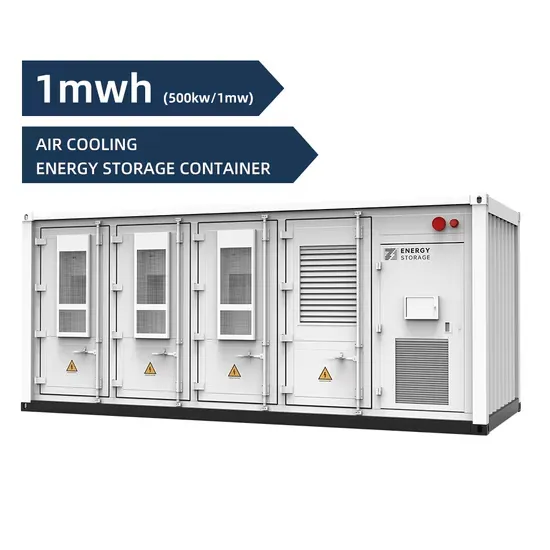

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

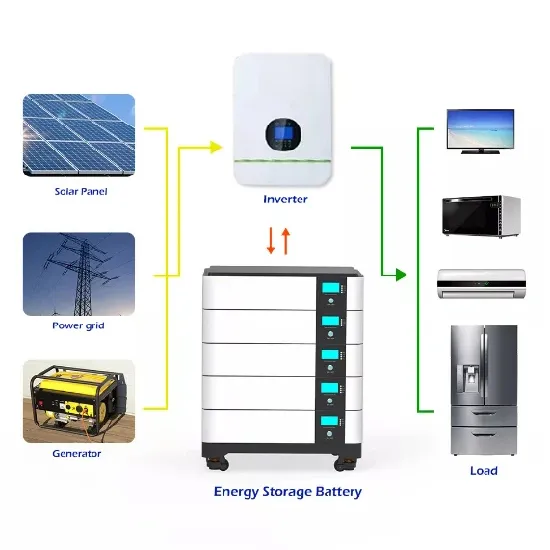

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.