How to calculate the annual solar energy output of a photovoltaic

Apr 22, 2025 · PV energy simulation : How to calculate the output energy or power of a solar photovoltaic system or panel.

The Environmental Impact of Solar Panel

Jan 30, 2024 · Solar panel production refers to the entire lifecycle of solar panels, from raw material extraction to manufacturing processes and end-of-life

Production cycle of solar panels: an introduction

Sinovoltaics explains the the production cycle of solar PV modules from pieces of raw material to the final electricity-generating panel. This article will provide

How are solar panels manufactured? | Solar

Jun 26, 2019 · We know solar panels as the futuristic-looking black or blue rectangles that soak up sunlight and bring down our energy bills. We might

Two U.S. solar production projects out of

Apr 3, 2025 · SPI''s panel-manufacturing plant in California has suddenly ceased operation and its cell-production site in South Carolina never got off the ground.

Steps and layout of solar module manufacturing

Oct 28, 2016 · Today the standard practice includes the construction of production lines that can handle the entire solar module manifacturing

Global Solar Power Tracker

Feb 11, 2025 · The Global Solar Power Tracker is a worldwide dataset of utility-scale solar photovoltaic (PV) and solar thermal facilities. It covers all operating

How to manufacture a photovoltaic module

5 days ago · Learn how to assemble and produce high-quality solar modules. By understanding the photovoltaic module production process and to learn which

Projects

Jul 28, 2025 · Over Easy Solar In 2023, Over Easy Solar commenced the production of their VPV Unit, specially designed for green and flat roofs. This

30MW Production Line

Aug 18, 2025 · See the 30MW production line for solar photovoltaic panels, efficient and scalable. Perfect for startups and expanding businesses.

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

Solar energy

Solar is the fastest growing energy source in the EU and is cheap, clean and flexible. The cost of solar power decreased by 82% between 2010-2020,

From Solar Dream to Reality: Your 6-Step Project

Oct 29, 2024 · Embark on a journey through the intricacies of solar project development, where each stage plays a crucial role in harnessing the power

Solar Manufacturing

6 days ago · What is Solar Manufacturing? Solar manufacturing refers to the fabrication and assembly of materials across the solar value chain, the most

Solar energy

The cost of manufacturing solar panels has plummeted dramatically in the past decade, making them not only affordable, but also often the cheapest form of electricity. Solar PV LCOE almost

PVknowhow : Make Your Own Solar Module

The global solar report project is a complex project that we have embarked upon to give our readers unique and deep insight into the metrics and statistics

KSA opens MENA''s largest solar panel

Nov 18, 2021 · The total area of the solar panel production factory in the Tabuk region exceeds 27,000m2, with an estimated production capacity of 1.2GW.

Solar Panel Manufacturing: A Comprehensive

Aug 9, 2023 · Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

Solar Panel Manufacturing : Process, Production

Mar 13, 2024 · Solar panel production involves several stages, including silicon processing, wafering, cell fabrication, module assembly, and testing. The

Life Cycle Greenhouse Gas Emissions from Solar

Jul 11, 2023 · Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics Over the last thirty years, hundreds of life cycle assessments (LCAs) have been conducted and published for a

Complete turnkey lines for pv panel production

5 days ago · Discover our complete turnkey lines for photovoltaic panel production. From start to finish, state-of-the-art lines designed for Solar Panels.

Turnkey Production lines for Solar Panels

5 days ago · Discover Ecoprogetti''s range of turnkey production lines, designed to optimize every aspect of solar panel manufacturing. Our solutions cater to

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · NREL researchers consider the full production processes of solar cells and modules when conducting bottom-up cost modeling. Historical and

How to Calculate Solar Panel Production for Free?

Learn to calculate your solar panel production for free. Tools, methods and tips to estimate your PV output and energy yield.

Basics of Solar Panel Manufacturing | Step-by

Jan 20, 2023 · The photovoltaic (PV) manufacturing process is the first step in the production of solar panels. This process involves the fabrication of PV cells,

Malaysia Solar Energy Profile: A Global Solar

Malaysia has emerged as an international hub for the manufacture of solar photovoltaic (PV) cells, wafers and modules. The southeast Asian nation has

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Sand → Silicon → Wafer → Photovoltaic Cell → Solar Panel. Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar

Solar Panel Production Line Provider

Aug 15, 2025 · Full Processes of Solar Panel Manufacturing Our turnkey PV module production lines are designed to reduce your footprints, with

Solar-Power-Datasets-and-Resources

Mar 23, 2023 · Open PV Project: This dataset provides information on the installed photovoltaic (PV) systems in the United States. It includes data on

Photovoltaic Cell Manufacturing Plant Report

The photovoltaic cell manufacturing plant project provides detailed insights into business plan, unit setup, cost, machinery and raw material requirements.

How Are Solar Panels Manufactured Step-by-Step? A Clear

Discover the step-by-step journey of solar panel manufacturing, from high-purity silicon wafers to final assembly and quality testing. Explore key components like PV cells, tempered glass, and

6 FAQs about [Photovoltaic project solar panel production]

What is a solar panel manufacturing plant?

A solar panel manufacturing plant is a highly specialized facility to manufacture photovoltaic (PV) modules that generate electricity from sunlight. Production normally includes silicon wafer fabrication, cell assembly, lamination, encapsulation, and framing.

What is a solar panel manufacturing process?

The manufacturing process is a multi-step operation that involves several unit operations, material handling, and quality checks. Below are the main stages involved in the solar panel manufacturing process flow:

What is solar energy production?

At the heart of solar energy production lies solar photovoltaic (PV) manufacturing. Photovoltaic refers to the process of converting sunlight directly into electricity, harnessing photons (units of light) to generate voltage. PV modules are the primary components in a solar panel, converting light directly to electricity.

What are the trends in solar photovoltaic technology?

Another notable trend is ongoing innovation in solar photovoltaic technology, such as improvements in panel efficiency and integration with energy storage systems. The use of bifacial panels, tandem cells, and perovskite-silicon hybrid modules is on the rise because they provide higher energy yields.

What is solar panel manufacturing plant project report 2025?

IMARC Group’s report, titled “ Solar Panel Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up a solar panel manufacturing plant.

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

Industry Information

- Israel 5G communication base station hybrid energy construction project

- Industrial and commercial energy storage battery equipment manufacturers

- Factory price bess electrical in Malaysia

- Waterproof design of new energy battery cabinet

- High quality single phase circuit breaker Factory

- Cheap transformer breaker in China exporter

- Photovoltaic energy storage configuration in Cameroon

- Bw DC variable frequency inverter

- Irish lithium energy storage power

- Energy storage power stations and energy storage containers

- Myanmar rooftop photovoltaic energy storage

- Wholesale battery and storage in New-Zealand

- What brand of lithium battery pack is good in Liberia

- 20W Solar Panel Wholesale Price

- Outdoor power supply is safe and good

- Large-Scale Energy Storage in Colombia

- Small power facility base station battery

- Jerusalem Outdoor Power Supply Agent

- Portable power supply suppliers in North America

- 1000 degree photovoltaic energy storage cabinet

- How to make outdoor energy storage cabinet base station

- Shanghai Sunshine Energy Storage Power Supply Dealer

- New 5000w24v inverter price

Commercial & Industrial Solar Storage Market Growth

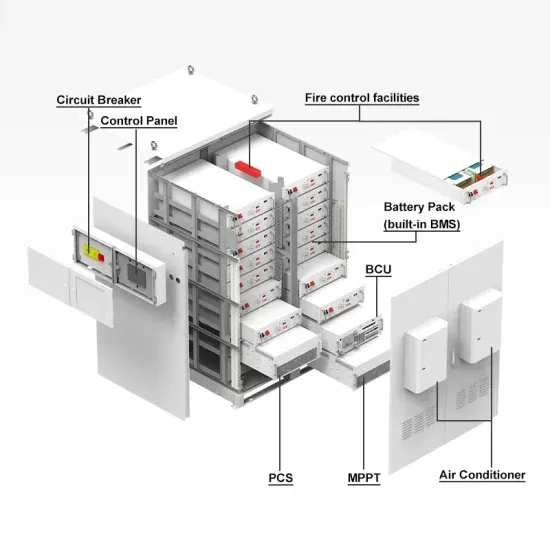

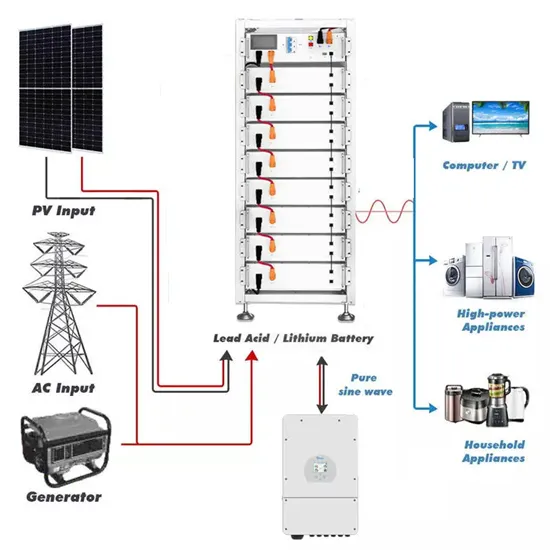

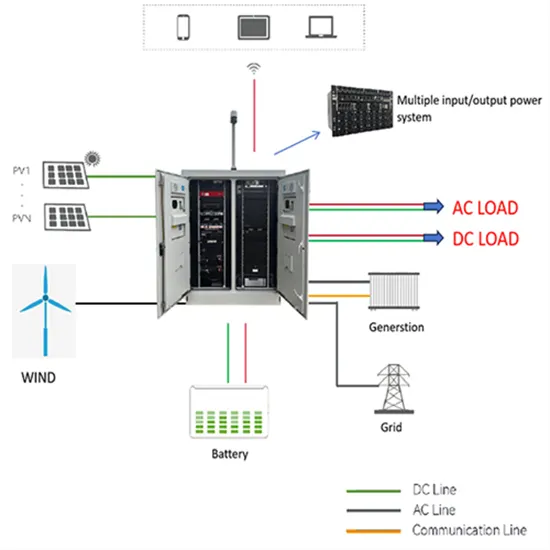

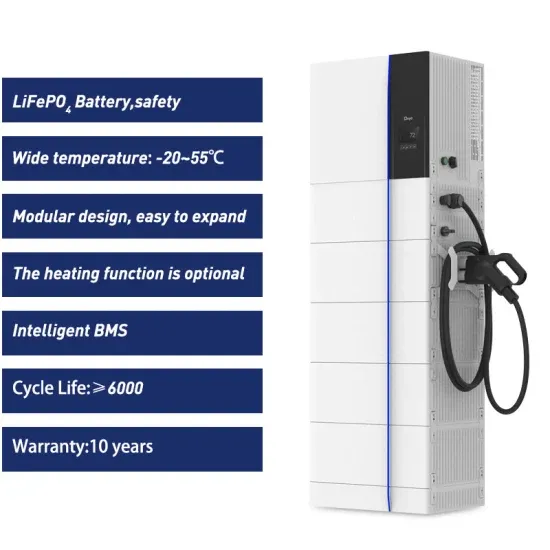

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.