An Overview of the R&D of Flywheel Energy Storage

Nov 9, 2024 · Flywheel energy storage (FES) is a kind of physics energy storage method exploiting a rotational block with kinetic energy that changes with the rotational speed varying

Can a Motor Output Flywheel Store Energy? Exploring Kinetic Storage

How Flywheels Turn Motion into a Power Bank At its core, a flywheel is a spinning rotor that stores energy through rotational inertia. When connected to a motor, it acts like a mechanical

High-performance flywheels for energy storage

One motor is specially designed as a high-velocity flywheel for reliable, fast-response energy storage—a function that will become increasingly important

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · Flywheels can store energy kinetically in a high speed rotor and charge and discharge using an electrical motor/generator. Wheel speed is determined by simultaneously

Flywheel Energy Storage: The Key To Sustainable

Oct 16, 2024 · Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan

An AMB Energy Storage Flywheel for Industrial

Mar 30, 2020 · 1. BACKGROUND A flywheel energy storage system has been developed for industrial applications. The flywheel based storage system is targeted for some applications

How do flywheels store energy?

Mar 31, 2023 · What does a flywheel do? Photo: A typical modern flywheel doesn''t even look like a wheel! It consists of a spinning carbon-fiber cylinder

A review on flywheel energy storage technology in fifty years

A single flywheel stored energy of 0.5~130 kW·h in charging or discharging with power of 0.3~3000 kW. The frontier technologies include new materials of flywheel rotor, super

Flywheel Energy Storage: A Comprehensive Guide

Discover the benefits and applications of flywheel energy storage in modern energy systems, including its role in grid stabilization and renewable energy integration.

An Overview of the R&D of Flywheel Energy Storage

Nov 5, 2024 · Flywheel energy storage (FES) is a kind of physics energy storage method exploiting a rotational block with kinetic energy that changes with the rotational speed varying

FESS Fkywheel Energy Storage Systems

Jun 26, 2025 · In Australia do flywheels have a role as energy storage devices? All flywheel energy systems use the same basic concepts to store energy.

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Flywheel Energy Storage System: What Is It and

In essence, a flywheel stores and releases energy just like a figure skater harnessing and controlling their spinning momentum, offering fast, efficient,

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

Flywheel Storage Systems | SpringerLink

Dec 17, 2019 · The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

A Review of Flywheel Energy Storage System

Sep 7, 2023 · The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

How long can flywheel energy storage be

Sep 26, 2024 · The growing importance of flywheel energy storage in contemporary energy systems cannot be overstated. This technology

Energy Storage Flywheels

The energy storage market is continuing to grow, bringing with it an increased demand for reliable flywheels. While lithium-ion and other battery types are the most commonly used energy

How much power does the flywheel energy

Apr 26, 2024 · Flywheel energy storage motors exemplify an exceptional advancement in power delivery solutions, merging high-efficiency mechanical

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

What is Flywheel Energy Storage? | Linquip

Apr 4, 2023 · A flywheel energy storage system employed by NASA (Reference: wikipedia ) How Flywheel Energy Storage Systems Work? Flywheel

Flywheel-lithium battery hybrid energy storage

Sep 2, 2020 · A hybrid energy storage system combining lithium-ion batteries with mechanical energy storage in the form of flywheels has gone into operation in

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

Development and prospect of flywheel energy storage

Oct 1, 2023 · Its working principle is based on the use of electricity as the driving force to drive the flywheel to rotate at a high speed and store electrical energy in the form of mechanical energy.

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Flywheel energy storage principle video tutorial

This document describes a flywheel energy storage system. It includes an introduction, block diagram, theory of operation, design, components, circuit diagram, advantages and

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

A novel flywheel energy storage system: Based on the barrel

Mar 1, 2022 · In this paper, a novel FESS is proposed form the configuration, material and its structure, and driving motor. The novel FESS uses all metal materials to achieve a lower cost;

Flywheel Energy Storage Calculator

The flywheel energy storage operating principle has many parallels with conventional battery-based energy storage. The flywheel goes through three

Design and Experimental Study of a Toroidal Winding Flywheel Energy

Jan 3, 2025 · In this study, a toroidal winding flywheel energy storage motor is designed for low and medium speed occasions, aiming to meet the challenges of conventional high-speed

Flywheel Energy Storage Basics

4 days ago · The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

6 FAQs about [Chad is a flywheel energy storage motor]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

Can flywheel energy storage systems be used for stability design?

The flywheel energy storage systems can be used for stability design in high power impulse load in independent power systems [187, 188]. A combined closed-loop based on the genetic algorithm with a forward-feed control system with fast response and steady accuracy is designed .

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

How to design a flywheel energy storage motor?

The design of the motor for flywheel energy storage mainly adopts the stator core, winding, magnet, and a matching optimization to improve the power and efficiency. The challenge in motor design is to reduce the loss of the permanent magnet motor rotor and prevent the failure of the motor caused by high-temperature rise. 3.3.

What is flywheel energy storage fess technology?

The principle of flywheel energy storage FESS technology originates from aerospace technology. Its working principle is based on the use of electricity as the driving force to drive the flywheel to rotate at a high speed and store electrical energy in the form of mechanical energy.

Industry Information

- Amsterdam s new energy storage base station power module

- Kigali Flow Battery Manufacturer

- Stockholm Industrial and Commercial Energy Storage Peak-Valley Arbitrage Program

- Wholesale wiring 220 breaker in Honduras

- Omega solar inverter for sale in Portugal

- Mobile solar container battery

- Ethiopia s energy storage boom

- El Salvador Super Energy Storage Battery Sales

- Botswana sine wave inverter price

- Portable power storage prices in Alexandria Egypt

- Photovoltaic inverter output

- Flywheel energy storage equipment for Zimbabwe communication base station

- Equatorial Guinea Smart Energy Storage Battery Customization Company

- Solar high power DC water pump

- How to navigate to the communication base station inverter

- Royu circuit breaker in China in Afghanistan

- Panama Colon three-phase uninterruptible power supply sales

- New energy battery cabinet custom manufacturer

- What is a solar charging system

- Chisinau energy storage container batch customization

- Energy storage container in Lagos Nigeria

- What are the common energy storage devices

- Warsaw 40-foot energy storage container

Commercial & Industrial Solar Storage Market Growth

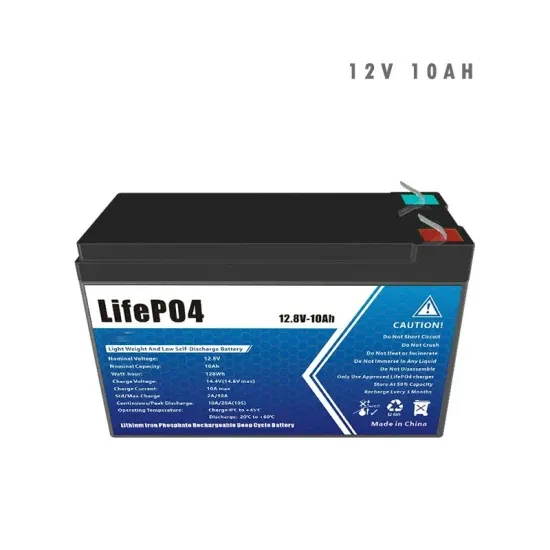

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.