Optimized design of liquid-cooled plate structure for flying

Sep 1, 2024 · Under the same conditions, a comparative simulation analysis of the performance of four different BTMS structures was conducted in terms of cooling efficiency, energy

Channel structure design and optimization for immersion cooling system

Jan 30, 2024 · A well-designed cooling architecture is a critical issue for solving the heat accumulation problem of the battery immersion cooling system (BICS). In this study, four

State of the Art Immersion Liquid Cooling Technology for

Apr 15, 2025 · Power battery immersion liquid-cooling technology involves directly immersing the battery in dielectric liquid to dissipate heat through convection or phase-change heat transfer.

A review on the liquid cooling thermal management system

Dec 1, 2024 · Therefore, it is necessary to explore a multi-objective optimization system to design liquid plate BTMS and use a unified evaluation system to assess the capability of LCP cooling

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Mar 19, 2025 · This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery

Design and optimization of the cooling duct system for the battery pack

Design and optimization of the cooling duct system for the battery pack of a certain container energy storage [J]. Energy Storage Science and Technology, 2020, 9 (6): 1864-1871. This

Exploration on the liquid-based energy storage battery system

Dec 1, 2024 · This also raises a question of which design is better suited for energy storage battery pack. 3) Lastly, low-temperature would bring severe degradation to LIBs, yet research

Battery energy storage system design: powering

Aug 16, 2023 · This article delves into the intricacies of battery energy storage system design, exploring its components, working principles, application

Optimization and thermal performance analysis of direct cooling

Aug 1, 2025 · The multi-channel battery thermal management system (BTMS) based on refrigerant direct cooling has the characteristics of high cooling efficiency and

Design of CTP liquid cooling battery pack and thermal

Dec 1, 2024 · Consequently, a novel battery pack integration method, CTP (Cell to Pack), has emerged as a potential solution. In order to enhance the integration degree and effective

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

Liquid-Cooled Energy Storage System

As the demand for high-capacity, high-power density energy storage grows, liquid-cooled energy storage is becoming an industry trend. Liquid-cooled

Boyd''s Liquid Cooling Solutions for Electric Vehicles

May 26, 2023 · Creating Competitive Advantage in eMobility Applications This paper addresses current and upcoming trends and thermal management design challenges for Electric Vehicles

Thermal management performance and optimization of a hybrid system

Jul 15, 2025 · Therefore, to broaden the thermal safety of energy storage battery pack, this work proposes a hybrid BTMS, which integrates topological fin design, passive PCM cooling, and

Optimization design of flow path arrangement and channel structure

Apr 1, 2025 · This paper can provide guidance on cooling plate design for high-performance and energy-sensitive battery thermal management systems.

Structural Design and Simulation Analysis of Cooling

Feb 15, 2025 · Based on the results of three key indicators of the battery pack, that is, the maximum temperature, the maximum temperature difference and pressure drop, 8 sets of

A novel water-based direct contact cooling system for

Jan 30, 2025 · Direct contact cooling technology is a promising method for addressing the thermal issues of lithium-ion batteries. However, the high cost of dielectric fluids used for direct contact

Advances in direct liquid cooling technology and waste heat

Oct 20, 2024 · Direct liquid cooling technology is one of the most promising energy-saving cooling technologies due to its advantages of high cooling efficiency, low noise, and reduction of hot

Experimental investigation of roll bond enabled direct cooling

Refrigerant-based direct cooling (RBDC) is innovatively implemented in multi-pack energy storage systems for enhanced thermal control. Lightweight, low-cost roll bond cold plates with hybrid

Immersion coupled direct cooling with non-uniform cooling

Apr 30, 2025 · This paper proposes and verifies a novel ICDC system based on coupled immersion cooling and direct cooling with a non-uniformly spaced cooling pipe design. Four

Heat transfer characteristics and influencing factors of

Jun 1, 2023 · In this article, the immersion coupled direct cooling (ICDC) method is proposed by immersing batteries in stationary fluid with direct-cooling tubes inserted in. Then, the heat

Design and simulation of battery thermal management systems

Mar 1, 2025 · With flexible blocks and libraries, engineers can simulate complex thermal dynamics, optimize cooling system design, and ensure consistent and safe battery pack

Immersion coupled direct cooling with non-uniform cooling

Apr 30, 2025 · Immersion cooling stands out for its high efficiency and temperature uniformity. This paper proposes an immersion coupled direct cooling (ICDC) system with non-uniformly

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Structural Design of the Refrigerant Direct Cooling

Apr 18, 2025 · Refrigerant direct cooling uses refrigerants as cooling media, combining the char-acteristics of indirect contact liquid cooling and traditional air conditioning systems. By

Optimized Design and Operation Control of

Jun 4, 2024 · A refrigerant direct cooling thermal management system is designed to give consideration to the thermal management of batteries and

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Mar 19, 2025 · Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery pack composed of 12 series-connected modules is constructed, adopting a

Thermal performance analysis and burning questions of

Sep 1, 2023 · This paper proposes a novel discrete model based on an electro-thermal coupling method and thermal resistance network to analyze the local temperature control performance

A novel thermal management system for lithium-ion battery

Sep 1, 2023 · The direct liquid cooling system shows preferable performance with high cooling efficiency and the extra function of fire suppression. However, the large quantity of liquid used

Essential technologies on the direct cooling thermal management system

May 20, 2021 · Based on the innovative development of cloud-controlling platform design and electronic and electrical architecture, the cloud battery controlling provides the chances for

Combined optimization of heat and space for industrial and

Mar 1, 2025 · Lithium battery is an important way of energy storage in human daily life. The energy storage pack is now widely used in the power generation side, the grid side and the

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

6 FAQs about [Direct cooling energy storage pack and system structure design]

Can non-uniformly spaced cooling pipes control lithium-ion battery thermal management?

This study presents a novel ICDC system utilizing non-uniformly spaced cooling pipes, exhibiting excellent thermal performance for lithium-ion battery thermal management. The system effectively controls battery pack temperature rise and ensures uniform temperature distribution, with notable cooling effects under high ambient temperatures.

Is direct liquid cooling more efficient than indirect cooling?

direct liquid cooling is more efficient than indirect cooling under the same total coolant flow for the pack. If the criteria for the battery cooling system design are set as T

What is a cooling pipe design scheme?

An innovative cooling pipe system design scheme is proposed, utilizing a coupled non-uniform spacing arrangement tailored to meet the heat dissipation requirements of different sections within the battery pack.

What is a direct liquid cooling system?

Direct Liquid Cooling SystemA direct liquid cooling system has high cooling capability and high compactness. In such a cooli g system, a basic cooling unit is formed by two cells with an aluminum heat sink plate inserted

Can a battery pack have a uniform coolant flow distribution?

packs. A design criterion is proposed for obtaining a uniform coolant flow distribution in the battery pack. Thermal behavior of the cells in both battery packs are simulated using 3D finite element models under 4C continuous discharge from a fully

How many cooling channels are there in direct liquid cooling?

In direct liquid cooling, the coolant flows to all the heat sink plates or co ling channels are in parallel. There are 48 cooling channels for a pack with 96 cells (Pack A in this study). All the cooling channels in the pack are integrated

Industry Information

- How much does a portable power bank usually cost

- Cylindrical lithium battery manufacturer

- Zimbabwe photovoltaic energy storage 30kw inverter brand

- Peru Power Grid Energy Storage Manufacturer

- Price of super long battery for energy storage cabinet

- Latvian energy storage battery container manufacturer

- Communication base station power supply construction

- Mauritania PV module prices

- Group purchase energy storage cabinet battery price

- Energy storage system monitoring architecture

- Replacement of lithium battery for power tools

- Solar light chasing system based on stm32

- China d curve circuit breaker in Brazil

- 72v lithium battery plus inverter

- The thinnest energy storage lithium battery

- Experts introduce outdoor power supply

- Niue Energy Storage New Energy

- System Integration Energy Storage in Lagos Nigeria

- Which portable battery cabinet is cheaper

- Central Africa Power Inverter for Sale

- Container energy storage photos

- Freetown Container Battery Charging CBC22

- Wholesale household inverters in Los-Angeles

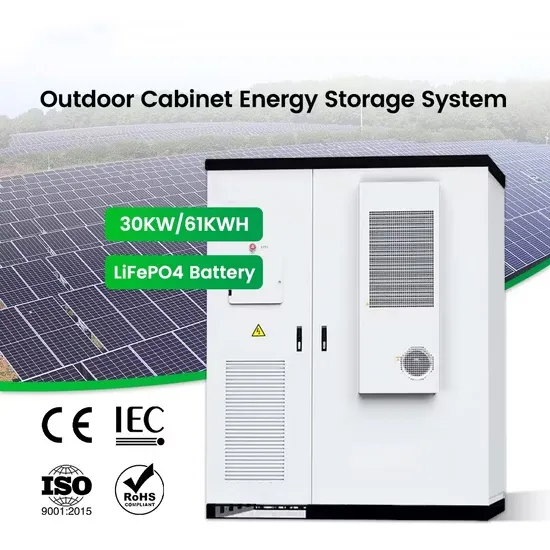

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.