5083 aluminum plate for side panels of new energy batteries

Sep 10, 2024 · The battery is the core component of new energy vehicles, and the power battery case and battery side panel provide certain protection for the internal battery. Due to

About the Structure Component of the Cover

Dec 9, 2023 · A critical element within these power batteries, the sealed aluminum pin, situated on the cover plate, assumes a crucial role in

New Energy Electric Vehicle Battery End Plate

Aug 5, 2025 · New Energy Electric Vehicle Battery End Plate, Find Details and Price about Aluminum End Plate End Plate from New Energy Electric Vehicle Battery End Plate -

How Aluminum-Ion Batteries Function and Why

Dec 18, 2024 · Aluminum-ion batteries could revolutionize energy storage. Learn how they work and why they may replace lithium-ion batteries.

New energy lithium battery steel shell vs new energy lithium battery

As the demand for sustainable energy solutions continues to grow, the importance of optimizing battery design and materials comes to the forefront. New energy lithium batteries are at the

New energy battery heating plate is damaged

Our study aims to address the issue of thermal management in lithium-ion batteries, particularly in extreme weather conditions. We propose a novel approach using hybrid cooling with wavy

5083 aluminum plate for side panel of new energy vehicle battery

Explore the innovative use of 5083 aluminum plates in the side panels of new energy vehicle battery cases. Understand its distinctive characteristics, functions, and applications within the

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

News

Jul 7, 2025 · What are the precautions for the use of new energy battery aluminum case? We all know that the aluminum shell of new energy battery is the source of power in electric vehicles.

Vehicle Battery Cover Sheet Aluminum 3003

Aluminum 3003 battery cover sheet 3003 aluminum sheet is a widely used material for new energy power battery cover and battery housing. 3003 alloy is

New energy vehicle battery tray

Mar 6, 2025 · The new energy vehicle battery aluminum tray adopts 6061 aluminum plate. Which meets the performance requirements of high precision, corrosion resistance, high temperature

New Energy Battery Aluminum Plate Extrusion Technology

Developed with the aim of expanding the pallet of aluminum solutions available for global high volume EV production, the Second-Generation of advanced aluminum sheet intensive design

structure of new energy vehicle battery PACK

May 5, 2024 · Research on the lightweight structure of new energy vehicle battery PACK cases Fasteners industry solutions By analyzing the research status of

Energy Storage Enclosures/Cabinets | Modular

Machan offers comprehensive solutions for the manufacture of energy storage enclosures. We have extensive manufacturing experience covering services

Cold Plate & Welding: Thermal Management

3 days ago · Cold Plate & Welding: Thermal Management Battery thermal management must address three key challenges: dissipating heat from and

3003 Aluminum Plate for New Energy Automobile Lithium Battery Power

Aug 16, 2025 · 3003 aluminum plate is a high-quality aluminum-manganese alloy, which is widely recognized for its excellent corrosion resistance, light weight and superior forming performance.

New energy aluminum battery case

Product Parameters Standard: European standard, national standard Aluminum alloy grade: 6061, 6063, 6005, 6082 and so on Length tolerance: ±0.2mm Wall thickness tolerance: ±0.05mm

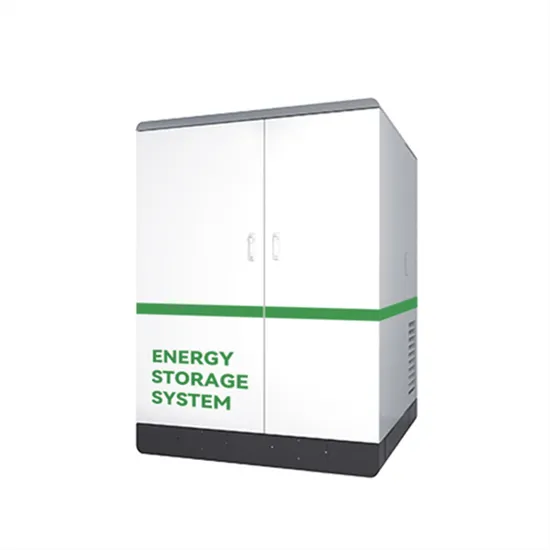

New Design 20kwh 30kwh Waterproof Electrical

Aug 16, 2025 · New Design 20kwh 30kwh Waterproof Electrical IP55 Solar Power Battery Cabinet, Find Details and Price about Battery Cabinet Energy Storage

Jtam-A4.dvi

Jan 13, 2024 · For new energy vehicles, the key component that affects vehicle safety is the battery pack. As the carrier of the battery, the importance of the battery pack cannot be

Battery Cabinets and Their Benefits

Sep 21, 2022 · Outdoor battery cabinets include an inside electrical system with many power ports for charging batteries in a contained environment.

New Energy Batteries_Shanghai Lingmachine Co., Ltd.

As an important link in the manufacturing process of new energy batteries, the problem of battery end plate deburring has also received increasing attention. Burrs not only affect the

Energy Storage

Made from strong and weather-resistant aluminum, these battery enclosures help to provide a storage component to help protect your battery (ies) from the

China New Energy Battery Cooling Plate manufacturers, New Energy

New Energy Battery Cooling Plate on sale manufacturers, find details about New Energy Battery Cooling Plate manufacturers, supplier and wholesaler - Trumony Aluminum Limited.

New Energy Vehicle Power Battery Aluminum

Jul 31, 2025 · Chalco''s production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays,

5083 Aluminum Plate for Side Panel of New

Jan 4, 2024 · Introducing the 5083 aluminum plate, a high-performance material ideal for the side panel of new energy vehicle battery cases. This aluminum

Top 10 lithium battery case manufacturers in China

5 days ago · Hard-shell battery structure (prismatic battery, cylindrical battery), mainly including battery case and cover plate, the cover plate is composed of

Aluminum batteries: Opportunities and challenges

Jun 1, 2024 · This article explores the potential and challenges of aluminum batteries, focusing on their applications, benefits, and limitations in energy storage.

New Energy Battery Housing Price | Supplier & Manufacturer

Shanghai Metal Corporation is manufacturer and supplier of New Energy Battery Housing. New Energy Battery Housing made of 3003 material is an aluminum alloy shell, ideally suited for

New Energy Battery Packing Aluminum Cold Plate

Offer New Energy Battery Packing Aluminum Cold Plate by China New Energy Battery Packing Aluminum Cold Plate manufacturers. Provide professional

New energy battery cabinet aluminum plate damaged

Chalco''s production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high

5 FAQs about [New energy battery cabinet aluminum plate damaged]

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

What is a power battery casing made of?

The material of the power battery casing is generally made of aluminum casing, because the aluminum casing has excellent lightweight structure, good thermal conductivity, and is safer and more durable.

What are energy power battery shells made of?

The new energy power battery shells on the market are mainly square in shape, usually made of 3003 aluminum alloy using hot rolled deep drawing process. Depending on the design requirements of the power battery, the thickness and width can be customized.

Which aluminum alloy is used in power batteries?

Aluminum alloy is a commonly used material for power batteries, and there is an urgent need to focus on research, development, and upgrading of products and alloy materials. At present, the conventional aluminum alloys used in power batteries mainly include 1-series, 3-series, 5-series, and 6-series.

What is a battery aluminum foil soft connection?

The battery aluminum foil soft connection is mainly used for flexible conductive connection inside or outside the battery module, which plays the role of current transmission of the battery pack and ensures the normal operation of the battery pack. Chalco's 1060 aluminum foil monolithic pure aluminum contains more than 99.6% of aluminum.

Industry Information

- Which is the best micro UPS uninterruptible power supply in Laos

- Mainstream products of energy storage cells

- Harare Home Energy Storage Battery Manufacturing Company

- 3500W Solar Street Light

- Emergency portable UPS power supply

- Which inverter is pure sine wave

- Algeria Industrial Container Wholesale

- Abkhazia 5g base station

- Flow battery working environment

- Bhutan energy storage product exports

- Communication base station inverter procurement service process

- Wind-solar hybrid communication base station system

- Where can I find a 12v inverter in Mauritania

- Recommended energy storage solar panels

- City communication base station battery setting density

- Minimum voltage of 48v lithium battery pack

- 240v circuit breaker in China in Japan

- 48v industrial frequency pure sine inverter

- Pakistan Karachi three phase inverter

- Battery cabinet shockproof baffle base station

- Vientiane outdoor power supply for sale

- Wholesale sf6 circuit breaker in Uae

- Inverter Battery Cabinet Base Station Power Technology

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.