The structure of the battery system of the Tesla

Download scientific diagram | The structure of the battery system of the Tesla Model S. from publication: Reliability Modeling Method for Lithium-ion Battery

The Structure Optimization of Lithium-ion Battery Pack

Oct 1, 2018 · To effectively improve the discharging efficiency and the cycle period, the thermodynamic analysis and the heat dissipation structure optimization are conducted on the

Structure of the 18,650 battery | Download

Download scientific diagram | Structure of the 18,650 battery from publication: Mechanical properties and thermal runaway study of automotive lithium-ion

In-depth analysis of electric vehicles battery pack structure

Jan 1, 2024 · Different models of EV battery packs have been analyzed to assess criticalities in the product structure and disassembly procedure. Regardless the absence of a standardized

EV Battery Pack Designs: An Overview

Apr 25, 2022 · A well-designed battery pack needs to compete with petrol-based engines when it comes to performance. That''s a real challenge because

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Structure and Behavior of Lithium-ion Batteries

6 days ago · The need to decrease greenhouse gas emissions has strongly increased the need for electric energy storage devices such as rechargeable

The Construction of a Lithium-Ion Battery Pack: An In-Depth

Jun 19, 2025 · In the evolving landscape of energy storage, lithium-ion battery packs have emerged as a pivotal technology, driving advancements in various industries. From electric

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Understanding Lithium Battery Pack Enclosure

May 7, 2025 · The enclosure holds all these parts securely and mounts the entire battery system to the EV chassis or boat structure. • Lower Case/Tray: This is

DOE ESHB Chapter 3: Lithium-Ion Batteries

Mar 17, 2021 · Li-ion batteries currently dominate the grid-scale battery market due to their extensive history in consumer products and growing production volumes for electric vehicles.

Structure of Lithium-ion Batteries & How They

Jan 11, 2025 · Learn the working module, structure, and key components of lithium-ion batteries for efficient energy storage and performance insights.

Lithium battery energy storage internal structure diagram

This article has sorted out the development process of batteries with different structures, restored the history of battery development in chronological order, and mainly analyzed the structural

A novel pressure compensated structure of lithium-ion battery pack

May 1, 2024 · The battery pack of deep-sea autonomous underwater vehicle (AUV) is placed in a heavy shell to protect the batteries from external pressure and moisture in a conventional

Internal structure of a lithium-ion battery.

Aug 11, 2025 · Here we report a chemical vapor deposition process to grow a graphene–silica assembly, called a graphene ball. Its hierarchical three

Key Concepts and Structure of EV Batteries: A

Feb 6, 2025 · EV battery 101: Learn the key concepts and structure behind electric car batteries in our beginner-friendly guide.

Exploring Lithium-Ion Battery Structure and

Jul 5, 2024 · Lithium-ion battery structure powers everyday devices. Explore its key components, operation, structures, design, manufacturing, safety, and

Review of Critical Battery Metals Resources in Botswana

Feb 13, 2023 · chemistries depend on the following five critical lithium-ion batteries Manganese is therefore EV of available graphite, EV development copper is critical for resources of mining

Structure of 18650 Li-ion battery. | Download

Download scientific diagram | Structure of 18650 Li-ion battery. from publication: The Explosive Nature of Tab Burrs in Li-Ion Batteries | Lithium-ion (Li-ion)

3 Different Shapes Lithium Battery Structures

Nov 11, 2019 · Different lithium battery structure means different characteristics, and each has its own advantages and disadvantages.

How to Design the Internal Structure of Lithium Battery

Jul 18, 2025 · For professional support in lithium battery pack design solutions, partner with CNSBattery—a leader in battery technology and solutions. CTA: Ensure optimal safety and

Lithium-ion Battery: Structure, Working Principle

Mar 21, 2022 · Hello everyone, I am Rose. Welcome to the new post today. Lithium battery is a kind of battery with lithium metal or lithium alloy as

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Efficient and reliable energy storage systems are crucial for our modern society. Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics

A Visual Guide to Li-ion Battery Structure

A lithium-ion battery, also known as a Li-ion battery, is a type of rechargeable battery that uses lithium ions as its primary active material. These batteries

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

How does the internal structure of a LiFePO4

May 19, 2025 · Our 51.2V100Ah Lithium Battery Storage Pack, 51.2V 200Ah Lithium Battery Module, and Lithium Battery Storage Pack are all designed

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · analyze the battery pack''s thermal distribution and its effect on the pack cycle use non-flammable case apply improved material (steel) to the case analyze the battery pack''s

The Construction of the Li-ion Battery Pack

Aug 6, 2025 · Learn about the various components that are needed to build a functional & safe battery pack in this week''s Li-ion Battery 101 blog.

What is the packaging technology of soft pack Li

Jun 11, 2022 · Soft pack lithium-ion batteries are always found in consumer electronics, as UAV/drone batteries, and the high-performance batteries of

A review on structure model and energy system design of lithium

Sep 1, 2014 · Abstract Structure properties of lithium-ion battery determine the specific energy and specific power of renewable energy vehicle and have attracted extensive concerns.

Internal structure of a lithium-ion battery.

Aug 11, 2025 · Download scientific diagram | Internal structure of a lithium-ion battery. from publication: The lithium-ion battery modeling challenge: A

Battery basic structure | Download Scientific

Download scientific diagram | Battery basic structure from publication: Simplified Heat Generation Model for Lithium ion battery used in Electric Vehicle | It is

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Fig. 1 shows the ideal battery pack and major constraints. The battery pack, as the main energy storage device for EVs, delivers the required energy and power with a reliable

Battery structure

3 days ago · The structure of the soft-pack lithium battery is packaged with aluminum-plastic film. In the event of a safety hazard, the soft-pack lithium battery is generally inflated first, or

The Handbook of Lithium-Ion Battery Pack Design:

Nov 11, 2015 · The Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and Terminology

Lithium-ion Battery: Structure, Working Principle and Package

This comprehensive article examines and compares various types of batteries used for energy storage, such as lithium-ion batteries, lead-acid batteries, flow batteries, and sodium-ion

Simple battery structure

Aug 16, 2025 · Learn about battery structure at Panasonic Energy Co., Ltd.''s Battery Education Academy. Science fun for kids.

6 FAQs about [The internal structure of the Botswana lithium battery pack]

What is the structure of lithium battery?

Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite. The electrolyte is usually a lithium salt dissolved in an organic solvent.

What are layered structures in lithium ion batteries?

The layered structures produce cells with sloping voltage profiles, where cell balancing is straightforward at any state of charge. The positive electrodes that are most common in Li-ion batteries for grid energy storage are the olivine LFP and the layered oxide, LiNixMnyCo1-x-yO2 (NMC).

Can lithium-ion batteries be used in mobile energy storage?

Lithium-ion batteries have a key role to play in mobile energy storage. One can potentially expand the envelope of lithium-ion battery performance, efficiency, safety, and longevity by using fundamental electrochemistry-based models for battery control. There ar... Cite Download full-text Contexts in source publication Context 1

How to use lithium-ion batteries correctly?

How to use lithium-ion batteries correctly? Avoid excessive discharge. When the device prompts "low battery", it should be charged; Don't charge until the device shuts down automatically. The battery has been discharging excessively. This can affect battery life. Avoid overcharging. The charger should be unplugged when it is indicated to be full.

What are lithium ion batteries made of?

In lithium-ion batteries, the substrate is often a very thin film of aluminum. The anode is the “negative” half of the battery cell and is usually made up of a thin copper substrate that is coated with the active anode material.

What is a soft-pack lithium battery?

The structure of the soft-pack lithium battery is packaged with aluminum-plastic film. In the event of a safety hazard, the soft-pack lithium battery is generally inflated first, or cracked to release energy from the seal, while the metal shell cell is more likely to produce a large explosion due to internal pressure.

Industry Information

- Energy storage lithium battery manufacturer in Izmir Türkiye

- How much electricity does a 5G base station require per kilometer

- Huawei Outdoor Communication Power Supply BESS

- Special energy storage battery manufacturer in Bergen Norway

- Burkina Faso container energy storage system manufacturer

- How much is the price of the small energy storage cabinet factory in Bloemfontein

- Palestine communication base station photovoltaic generator manufacturer

- Berlin container energy storage manufacturer

- Inverter for solar panels

- Is the inverter voltage insufficient to cause a power outage

- Cheap factory price furnace breaker Factory

- Photovoltaic inverter can see the power generation

- Ouagadougou portable energy storage battery customization

- Guyana Energy Storage Container Telecommunication Power Plant Operation

- Myanmar power storage vehicle manufacturer

- How many volts does a 550 watt solar panel generate

- Factory price 7 5 kw inverter in Uae

- Factory price bess electrical in Burundi

- What are the technical requirements for battery cabinets

- Slovenia makes photovoltaic solar panels

- Africa Energy Storage Power Station

- What are the requirements for phase change energy storage systems

- Libya Communication BESS Power Station Manufacturer

Commercial & Industrial Solar Storage Market Growth

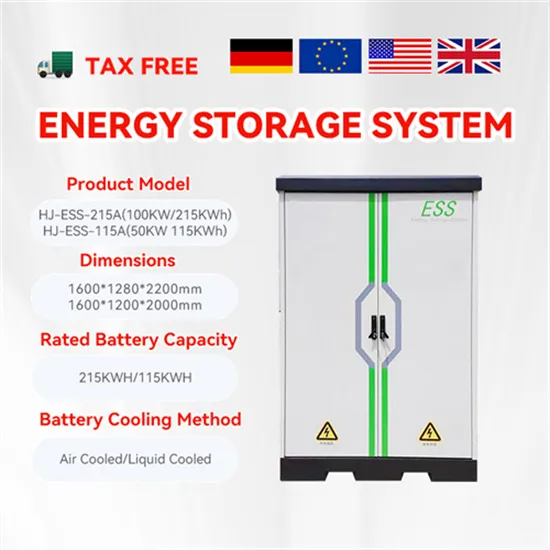

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.