Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

13 battery gigafactories coming to the US by 2025

Dec 28, 2021 · There are 13 new battery cell gigafactories coming online in the US by 2025, according to the Department of Energy. These factories are ushering in a new era of battery

castries battery technologies

American Battery Technology Company is uniquely positioned to supply low-cost, low-environmental impact, domestically-sourced battery metals through its three divisions: lithium

Doesn t Castries produce lithium batteries

Lithium-ion battery production is rapidly scaling up, as electromobility gathers pace in the context of decarbonising transportation. As battery output accelerates, the global production networks

Lithium Battery Industry Castries

Who is China Aviation lithium battery technology (CALB)? CALB (short for China Aviation Lithium Battery Technology) is among the top five Chinese battery manufacturers specializing in the

Reliance to enter Lithium-ion battery

Aug 29, 2023 · Notably, Reliance New Energy Battery Storage Ltd. is one of the companies selected under MHI''s PLI scheme for Advanced Chemistry Cell

Battery Giant CATL Inks Deal With Shanghai to Base Int''l HQ

Shanghai is home to Tesla''s only vehicle assembly plant outside of the United States. CATL will build its new plant in the same area as Tesla''s Gigafactory 3. In June, the pair extended a deal

China battery giant CATL is expanding globally: Here''s why it

Jun 27, 2025 · The battery maker has already established a wholly owned manufacturing base in Germany, which first opened in 2023. It has also announced plans to build a battery plant in

Company Profile

6 days ago · Yibin Plant was certified as the world''s first zero-carbon battery factory and was selected as a member of the Global Lighthouse Network by

Lithium-ion battery manufacturing: Here''s what

Mar 2, 2023 · Lithium-ion (Li-on) battery production in the U.S. is on the rise. A graphic about projected growth in worldwide battery manufacturing caught my

Castries lithium battery project bidding information

What will Imerys do with British lithium? The transaction will bring together Imerys'' expertise in mining, infrastructure in Cornwall, R&D and process development capabilities, as well as its

Report: CATL''s New Battery Plant In Shanghai Already

CATL shows some extreme expansion pace, as its latest lithium-ion battery plant in Lingang, Shanghai, China reportedly started production. We first heard about the project in June 2021,...

CASTRIES ENERGY STORAGE SYSTEM PLANT

Are battery electricity storage systems a good investment? This study shows that battery electricity storage systems offer enormous deployment and cost-reduction potential. By 2030,

Lithium-Ion Battery Recycling Manufacturing Plant Report 2025

IMARC Group''s report on lithium-ion battery recycling manufacturing plant provides detailed insights into business plan and setup cost.

Battery Plant Design Do''s and Don''ts

Sep 15, 2023 · Battery factories require a new way of thinking about plant design and construction. Manufacturing engineers must pay careful attention to

Battery Storage Shipping Containers | S Jones

5 days ago · Secure industrial battery storage containers, rooms and enclosures designed and built by the market leaders in container conversions.

Lithium Battery Industry Castries

List of Castries lithium battery OEM companies tive strides of lithium battery manufacturers. As businesses and industries pivot toward sustainable and efficient power solutions, the demand

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

PRESS RELEASE: Lyten Announces Plans to Build

Oct 15, 2024 · "Nevada is emerging as a key hub for U.S. battery manufacturing, and Lyten''s choice to build the world''s first lithium-sulfur battery gigafactory

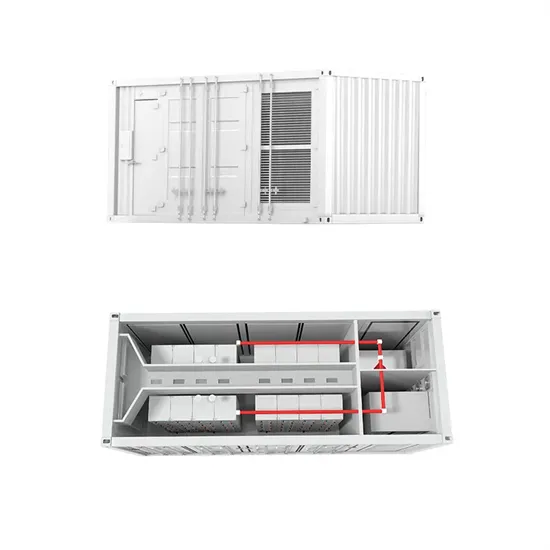

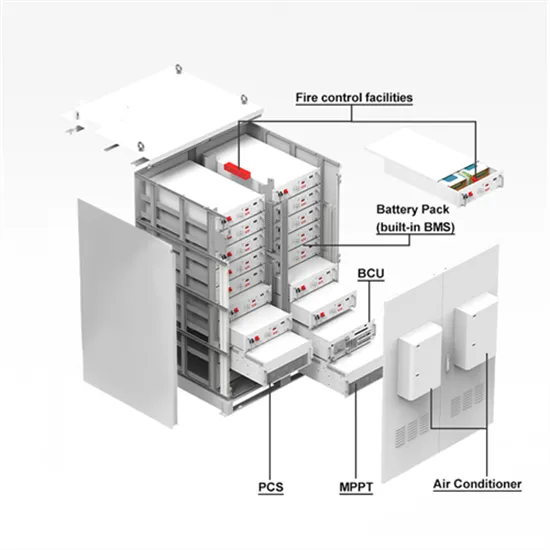

What Is A Battery Container?

Nov 4, 2024 · The term "battery container" specifically refers to the physical container, usually a standardized shipping container, that houses the battery

Here are the 4 Top Considerations in Lithium-Ion

Sep 6, 2021 · Lithium-ion battery manufacturing demands the most stringent humidity control and the first challenge is to create and maintain these ultra

Saft expands battery production in the US to

Sep 10, 2024 · Saft, a subsidiary of TotalEnegies, has commissioned a new line at its Jacksonville factory in Florida to produce lithium-ion battery containers in

The first wholly US-owned li-ion battery factory

Mar 2, 2023 · KORE Power chose Siemens as its infrastructure tech partner for its li-ion battery factory – the first to be wholly owned by a US company.

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · Electrode manufacturing Cell assembly Cell finishing The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell

Lithium battery under construction in Castries

What is clay Tye battery energy system storage plant? FRV and Harmony have begun construction works of Clay Tye Battery Energy System Storage Plant. With 99MW / 198MWh it

Sanvaru

Sanvaru in collaboration with renowned technical institutions around the world in Lithium-Ion Battery Systems space provide Training Program that is designed

Energy Insider: China to Restrict Export of Lithium Battery

Jan 7, 2025 · What''s new: China is considering restricting the export of some technologies used in the production of lithium-ion batteries, the core power source for electric vehicles (EVs) and

Reliance building largest battery plant in India

Sep 2, 2024 · Reliance Industries has committed INR 75,000 crore (almost 9 billion USD) to establish an integrated manufacturing ecosystem for solar

What Are Lithium Battery Storage Containers and Why Are

Apr 11, 2025 · Lithium battery storage containers are specialized units designed to safely store and manage lithium-ion batteries, mitigating risks like thermal runaway, fires, and explosions.

A Global Tour of Upcoming Battery Production

May 25, 2023 · Swedish lithium-ion battery manufacturer Northvolt has announced plans to invest several billion euros in building a gigafactory in

6 FAQs about [Castries Lithium Battery Container Manufacturing Plant]

Where is CATL's new lithium-ion battery plant located?

The site is located just about 3 km from Tesla Giga Shanghai. CATL shows some extreme expansion pace, as its latest lithium-ion battery plant in Lingang, Shanghai, China reportedly started production. We first heard about the project in June 2021, when Reuters reported about 80 GWh battery plant that CATL intendeds to build in Shanghai.

Where are CATL batteries made?

Headquarters: Ningde, Fujian Overview: CATL is one of China’s largest lithium-ion battery manufacturers and a global leader in battery manufacturing. Key Products A leading manufacturer focuses on high-performance EV batteries with continuous innovations for enhanced energy density, longevity, and safety.

Will CATL build a battery plant in Michigan?

Bloomberg reported last month that CATL and Ford Motor Co are considering building a battery manufacturing plant in Michigan, the United States, with a multibillion-dollar investment. In August, the battery giant invested 7.34 billion euros in building a 100 gigawatt-hour battery plant in Debrecen, Hungary.

Does CATL manufacture lithium-ion batteries?

Despite the unstable global supply chain due to the COVID-19 pandemic, CATL announced in late December that it had achieved mass production of lithium-ion battery cells as scheduled at its factory in the German state of Thuringia.

What's going on with CATL's new battery plant?

Anyway, here we are in January 2022, and according to media reports (via CnEVPost ), CATL's new battery plant is ramping-up production and already achieved 60% of undisclosed target capacity. The local media outlet Shanghai Observer reported that the new plant started sending batteries to Tesla in November. We are assuming that those are LFP cells.

Will CATL build a new battery plant in 2021?

We first heard about the project in June 2021, when Reuters reported about 80 GWh battery plant that CATL intendeds to build in Shanghai. Later in the same month, Tesla signed a new supply deal with CATL that would run from January 2022 to December 2025.

Industry Information

- New Energy Battery Cabinets for Sale in the Marshall Islands

- Which energy storage power supply is better in Zambia

- Slovenia local uninterruptible power supply BESS company

- Photovoltaic energy storage equipment manufacturing project

- What are the specifications of a single-sided photovoltaic panel

- 100kw flywheel energy storage

- Commonly used lithium battery packs

- Cheap 2000w solar inverter in China exporter

- Photovoltaic hybrid sine wave inverter

- Bandar Seri Begawan outdoor power supply field scale

- 5g base station capacitor function

- Danish Aarhus Power Storage Vehicle Equipment Company

- 1200kw site energy storage cabinet

- Sukhumi Energy Storage New Energy

- 12v to 220v inverter for sale in London

- Wholesale bess battery system in Bangkok

- Which type of photovoltaic energy storage cabinet is the best

- Photovoltaic inverter double closed loop

- Spanish energy storage container sales

- Algiers Power Station Photovoltaic Panel Manufacturer

- Huawei Beirut Energy Storage Power Station

- Andorra City Home Energy Storage Channel

- Photovoltaic solar panels have a strange smell

Commercial & Industrial Solar Storage Market Growth

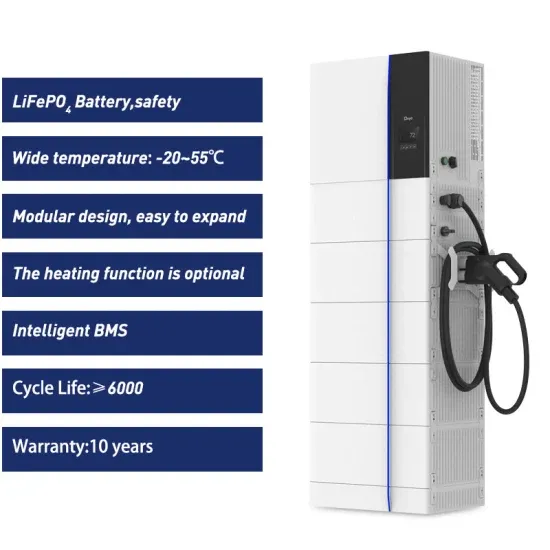

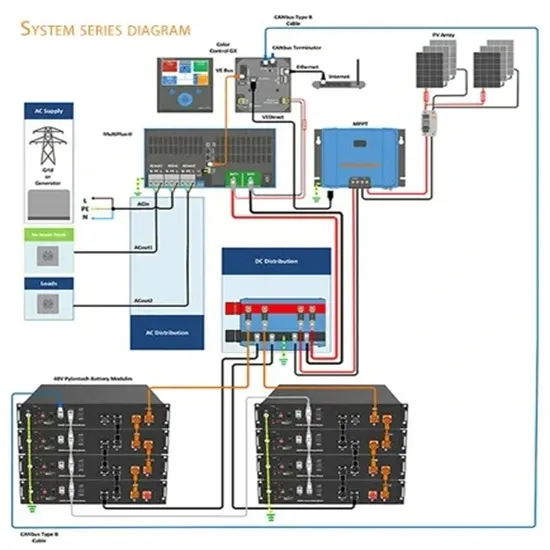

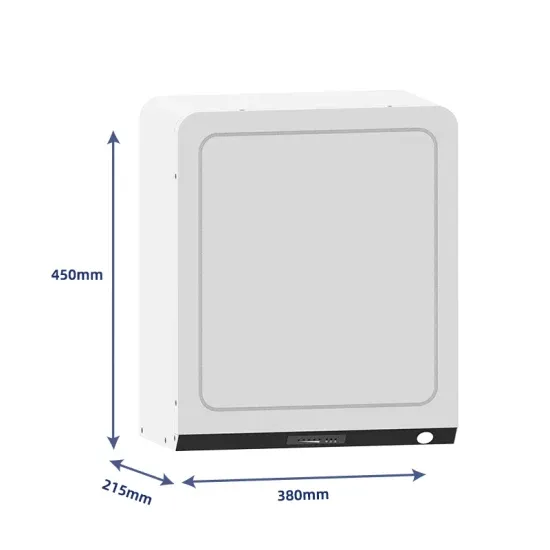

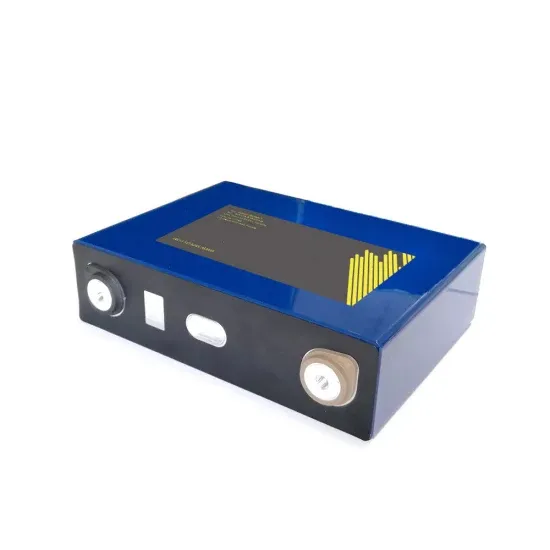

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.