Small & Medium-sized Insulation Panel Processing Machine

Jul 9, 2024 · Sinowa is committed to the development and manufacturing of high-end and high-efficiency small & medium-sized insulation panel processing machine. Our sandwich panel

Comparison of waste photovoltaic panel processing

Sep 15, 2023 · This work aims to compare end-of-life (EoL) alternative processing scenarios of waste photovoltaic panel in Australia. Landfill, generic waste electri

Understanding the Price of Photovoltaic Panel Special

If you''ve ever wondered why photovoltaic panel equipment prices keep evolving, look no further than the 28% annual growth in global solar installations. Manufacturers, engineers, and project

Solar photovoltaic panel processing equipment

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product''s quality and efficiency: Silicon Ingot and Wafer

Photovoltaic panel processing equipment operation

Mar 28, 2023 · This guide considers Operation and Maintenance (O&M) of photovoltaic (PV) systems with the goal of reducing the cost of O&M and increasing its effectiveness. Reported

Solar (photovoltaic) panel prices

Nov 15, 2024 · Solar (photovoltaic) panel prices This data is expressed in US dollars per watt, adjusted for inflation.

Solar Panel Manufacturing Machines

Feb 6, 2025 · Find solar panel manufacturing machines for efficient PV module production. Our automatic and manual solar cells making machines for top-tier quality.

How much does a set of solar photovoltaic panel production

Dec 4, 2023 · In short, the price of a photovoltaic panel production line equipment is influenced by various factors, and enterprises need to choose suitable equipment and services based on

Grid-connected photovoltaic power systems: Technical and

Jan 1, 2010 · Small and medium-sized stand-alone PV systems of 5–100 kWp, and large-sized systems of greater than 100 kWp, have been extensively disseminated. The design of central

Photovoltaic Panel Recycling Equipment | SUNY

With the rapid development of renewable energy, photovoltaic panels play an important role in solar power generation. However, when photovoltaic panels

Understanding the Price Factors of Photovoltaic Glass Post-Processing

Why Photovoltaic Glass Post-Processing Equipment Prices Matter Photovoltaic (PV) glass post-processing equipment is the backbone of solar panel manufacturing. Whether you''re a solar

The Role of Machinery in PV Production | Eco

In this article, we''ll explore the key machines driving PV module production, their roles in the process, and how they are shaping trends in the solar industry.

Photovoltaic Price Index

Notes on reading the PV price index Only tax-free prices for photovoltaic modules are shown. The prices stated reflect the average offer prices in retail and on the European spot market

What Are the 9 Startup Costs for a Solar Panel

Jul 24, 2025 · Discover the 9 startup costs for a solar panel manufacturing plant. Learn about equipment, facilities, and operational expenses for success.

How much does a solar processing machine

Feb 20, 2024 · The price of a solar processing machine can vary significantly based on several factors, 1. the type of machine, 2. production capacity, 3.

Commercial Solar Panels in the UK: Guide

Jun 11, 2025 · Commercial solar panels can cost approximately between £16,000 - £60,000 (20kW to 50kW systems) for small to medium-sized businesses. On

Photovoltaic panel processing equipment factory

Sep 6, 2020 · The next step in the solar panel manufacturing process is lamination. 2 · A photovoltaic panel recycling and processing equipment can process 500kg-2000kg of waste

Solar Panel Recycling Machine Cost and Business

Jul 4, 2023 · Let me introduce the cost of solar panel recycling technology equipment and discuss how to start a solar panel recycling business. The

Solar PV Module Manufacturing Cost Analysis | Case Study

According to an IMARC study, the global solar PV module market size reached 1,386.1 TWh in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 14.36%

Development of PV panel recycling process enabling

Jul 1, 2025 · The cumulative PV panel waste is expected to reach ≈8 million tonnes by 2030 and ≈ 80 million tonnes by 2050. This presents an opportunity to pursue new avenues in terms of

Utility-Scale Solar Energy: A Complete Guide

May 12, 2024 · The most visible components of a solar power plant are the photovoltaic (PV) panels, which convert sunlight directly into electricity. PV

How much does the photovoltaic panel production line equipment cost

Investing in a photovoltaic panel production line is a complex and high cost decision, with equipment prices varying due to multiple factors, typically ranging from tens of millions to

Solar photovoltaic panel processing equipment

Jan 6, 2024 · The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product''s quality and efficiency: Silicon Ingot and

How PV Machines Frame Solar Modules: Sorting

Apr 16, 2023 · The frame of a solar panel equipment serves a dual purpose. Firstly, it provides structural support for the module, ensuring it can withstand

PV Module Manufacturing Equipment Market

Feb 9, 2025 · Module production costs fell to $0.13/W in 2023, down 18% from 2020 levels, with equipment advancements contributing 35% of these savings through improved throughput and

Solar Panel Manufacturing Plant Costs: 6 Crucial Insights

Feb 2, 2023 · For example, a medium automated 100 MW line would cost approximately 1.5-2 million Euros. Prices vary based on the level of automation and technology used. If you are

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride,

Photovoltaic panel processing equipment factory

The manufacturing typically starts with float glass coated with a transparent conductive layer,onto which the photovoltaic absorber material is deposited in a process called close-spaced

Solar Panel Cost in 2025: How to Estimate The

Jul 4, 2025 · The average solar panel cost has declined dramatically over the last decade, and solar systems now offer more value to homeowners than they

Profitability analysis of a photovoltaic installation

Dec 15, 2022 · The investment costs of the photovoltaic installation (purchase: photovoltaic panels, inverter, assembly structure, DC cabling, AC cabling, connection equipment, junction

Solar Photovoltaic System Cost Benchmarks

Aug 19, 2025 · The U.S. Department of Energy''s solar office and its national laboratory partners analyze cost data for U.S. solar photovoltaic systems to

Solar Panel Manufacturing Machines

Find solar panel manufacturing machines for efficient PV module production. Our automatic and manual solar cells making machines for top-tier quality.

Price list of photovoltaic panel frame assembly machines

Nov 30, 2023 · China Solar Panel Framing Machine wholesale - Select 2024 high quality Solar Panel Framing Machine products in best price from certified Chinese Machine For Metal

Medium-sized photovoltaic panel processing equipment

We provide a wide range of manufacturing equipment for thin film (compound, organic, perovskite, etc.) and next-generation PV modules utilizing our 30 years of experience and expertise

6 FAQs about [Price of medium-sized photovoltaic panel processing equipment]

What is the global solar PV module market size?

According to an IMARC study, the global solar PV module market size reached 1,386.1 TWh in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by 2033. A number of important factors are driving the market for solar PV modules.

What is the production capacity of solar PV module?

The proposed facility is designed with an annual production capacity of 1,000 MW (1 GW) of solar PV module. Manufacturing Process: The first step in the production of solar PV modules is the melting and solidification of high-purity silicon pieces into polycrystalline ingots.

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

What are polycrystalline solar photovoltaic (PV) modules?

Polycrystalline solar photovoltaic (PV) modules are a key component of solar energy systems, harnessing sunlight and converting it into electricity through the photovoltaic effect. These modules are composed of multiple interconnected solar cells, each made from polycrystalline silicon.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

What are the different types of solar production machines?

Solar (PV) production machines come in a wide range of sizes. You can start with a very small line (for example, 25 MW) using refurbished equipment, or you can opt for brand new machines. Brand new machines range from 50 MW (the smallest size) to fully automated lines with 1 GW capacity or more.

Industry Information

- Hargeisa Large Industrial and Commercial Energy Storage Cabinet

- Outdoor power supply discharge power

- Solar inverter prices in Kiev

- Best China single circuit breaker supplier

- West African pulse inverter manufacturers recommended

- How long is the telecom battery cabinet

- Boron Carbon Solar Photovoltaic Panel

- Double glass components transmit light

- Brazil Telecommunication Base Station Lead-acid Battery Tender

- Croatia Solar PV Panel Purchase Costs

- Photovoltaic panel charging 24 volt battery

- Palestine Solar PV Modules

- Is a 6-watt solar panel powerful enough

- Libya crystalline silicon photovoltaic curtain wall

- Vienna charging pile lithium battery energy storage cabinet customization

- Lesotho Solar Water Pump

- Paramaribo Container Energy Storage Power Station Company

- Is the photovoltaic off-grid inverter good

- Huawei Energy Storage Box Photovoltaic Power Supply

- Berne household rooftop power station energy storage lithium battery foreign trade

- 12 volt solar 200 watts

- 545W photovoltaic panel inverter

- Bangladesh Water Pump Inverter Manufacturer

Commercial & Industrial Solar Storage Market Growth

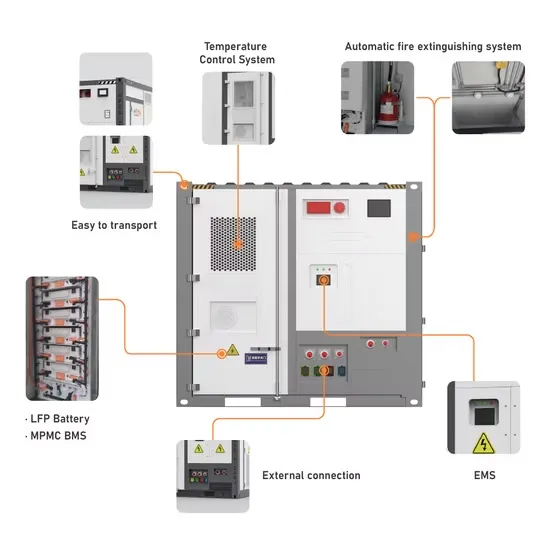

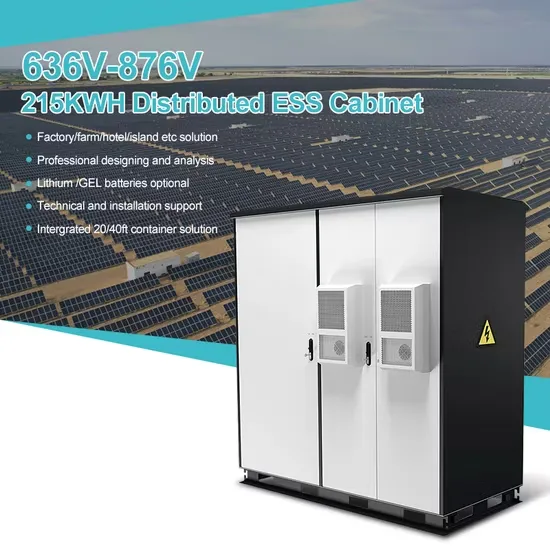

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

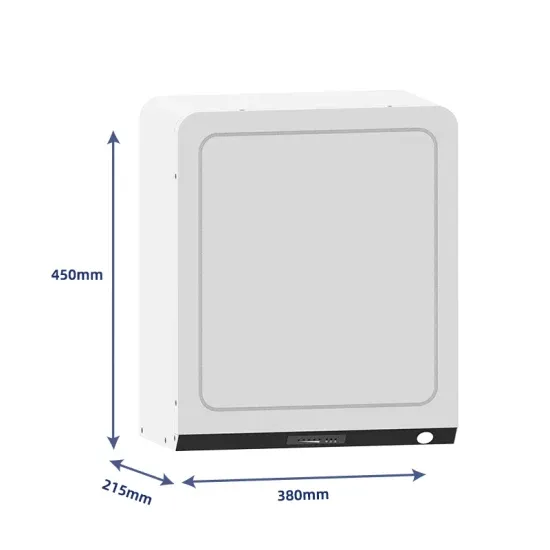

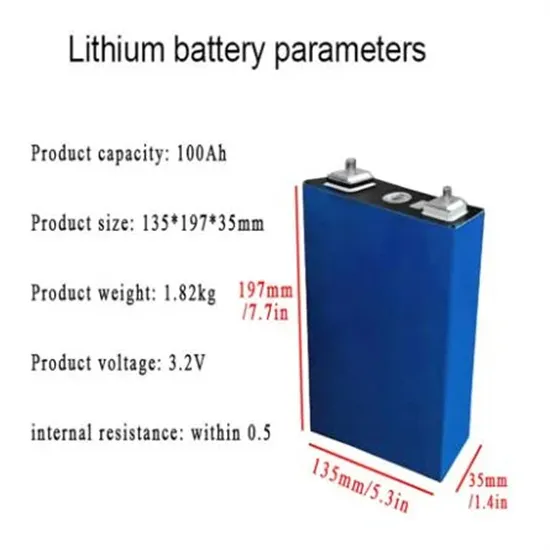

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.