Double Glass Solar Panels Half Cell Mono PERC

Apr 11, 2021 · Double glass solar panels with advanced PERC technology, half-cell and frameless design enable lower degradation, high power and longer life.

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Mar 31, 2025 · IMPORTANT SAFETY INSTRUCTIONS This manual contains important safety instructions for the Solar Photovoltaic Modules (hereafter referred to as "Modules") of JA Solar

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · The choice of glass in a PV module has become a key consideration in efforts to improve durability in the face of extreme weather

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Bifacial solar panels: What you need to know

Oct 11, 2024 · The technology behind solar panels continues to evolve and improve. Manufacturers are now able to produce bifacial panels, which feature

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

JinkoSolar: Transparent backsheet vs dual glass

Mar 10, 2020 · Based on a study of the two types of bifacial products and a long-term outdoor performance test carried out by JinkoSolar, comparisons from multiple perspectives are

Towards 50 Year Lifetime PV Modules: Double Glass vs. Glass

Mar 29, 2024 · Bifacial modules with double glass architectures have been deployed to capture the rear-side irradiance thereby increasing the light captured. The choice of a double glass

JinkoSolar: Transparent backsheet vs dual glass

Mar 10, 2020 · Transparent backsheet can successfully decrease module weight and the difference between the glass-transparent backsheet module and the

For N-type Bifacial Technology, Dual Glass Structure is

Feb 28, 2023 · Interest in N-type bifacial modules has rapidly increased due to their ability to generate more power than conventional P-type bifacial thanks to their higher bifacial factor,

Double the strengths, double the benefits

Feb 21, 2025 · Explore IBC SOLAR''s double glass module offerings At IBC SOLAR, we are committed to providing cutting-edge photovoltaic solutions

The weekend read: Double glass can spell

Feb 23, 2019 · Glass-glass modules are built to survive the toughest conditions and can deliver module lifetimes far exceeding the 20-30 years expected of

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Bifaciality: The bifaciality of double glass modules produces a gain of around 10-11% compared to the power measured on the front panel alone, for TOPCon type modules

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of

What Are Bifacial Solar Panels – A Complete Guide

Jun 19, 2023 · The double-glass structure of bifacial solar panels can offer improved durability and longevity compared to traditional solar panels. The

What is the Double Glass (Dual Glass)

Apr 18, 2022 · glass-glass is making a comeback, based on an increase in the market share of bifacial modules and an increase in the number of PV

Bifacial Photovoltaics 2021: Status, Opportunities

Dec 11, 2020 · The reason for this is that bifacial solar cells are the result of an evolution of crystalline Si PV cell technology and, at the same time, module

Glass-Glass Solar Panel Technology

glass-glass is making a comeback, based on an increase in the market share of bifacial modules and an increase in the number of PV installations on a

The Difference Between Bifacial Module and

Sep 4, 2023 · Double glass bifacial modules are typically frameless and can be installed with both sides exposed to sunlight. Key differences between the two

Dual-glass vs glass-backsheet: The winning

Oct 19, 2022 · Compared with standard glass backsheet technology, framed modules with two layers of glass are heavier. Therefore, transparent

High performance double-glass bifacial PV modules

Oct 5, 2016 · High performance double-glass bifacial PV modules through detailed characterization Yong Sheng Khoo, Jai Prakash Singh, Min Hsian Saw Solar Energy

Bifacial solar panels: Benefits & Installation

What is a bifacial solar panel? A bifacial solar panel is a type of solar module that is designed to capture sunlight on both the front and rear sides. Unlike

Bifacial Solar Panels: What are They and Are

Apr 14, 2024 · Bifacial solar panels offer many advantages over monofacial solar PV modules. They represent an innovation in solar panel design and are

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Bifacial PV modules & systems

Apr 27, 2021 · Bifacial photovoltaic modules at Sandia National Laboratories, Joshua S. Stein ISBN 978-3-907281-03-1 Task 13 Performance, Operation and Reliability of Photovoltaic

Double glass solar module | Maysun Solar

Why Choose Double Glass Solar Modules? Glass-glass solar modules (bifacial modules) increase energy production by approximately 2% to 5% compared to

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · ECONOMICS Bifacial G2G technology is a turning point in photovoltaic (PV) system technology. It replaces costly single-axis and double-axis mechanical tracking systems with

Overall Performance Losses and Activated Mechanisms in Double Glass

Jun 10, 2022 · Commercial PV modules have various packaging choices nowadays, which influence their long-term reliability. This study compared the degradation behaviors of sixteen

Dual-glass vs glass-backsheet: The winning

Oct 19, 2022 · In contrast, the glass found in our dual glass modules is a kind of inorganic material with relatively superior weather resistance, which

Bifacial Solar Modules | Maysun Solar

Bifacial photovoltaic modules are available in two types: single-glass bifacial modules and double-glass bifacial modules. Single-glass bifacial modules are

Flexible vs. Rigid Double-Glass Solar Panels:

These panels consist of photovoltaic cells made from silicon wafers arranged together and encased in tempered glass and aluminum frames. As an

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

What are the differences between single-glass

Oct 22, 2020 · As a high-quality manufacturer and supplier of Double Glass Solar Panels, solar modules, and Solar Panels, we provide you with high-quality

Towards large-scale deployment of bifacial photovoltaics

Jun 8, 2018 · Low photovoltaic module costs imply that increasing the energy yield per module area is now a priority. We argue that modules harvesting sunlight from both sides will strongly

Presentation

Jun 1, 2023 · 2 Market Trends for Glass-Glass or Double Glass PV Modules ITRPV 2018 report shows: Glass-glass modules are increasing in market share Frameless modules are

JA Solar 595W JAM72D40 MB N-type Double

The JA Solar JAM72D40 MB modules from the DeepBlue 4.0 series deliver 570–595W with high-efficiency Mono-PERC cells and 16 busbars. Featuring a

6 FAQs about [Double-glass and bifacial photovoltaic modules]

Does Trina Solar have a dual glass bifacial module?

However, Trina Solar has made such a breakthrough by abandoning the backsheet and developing the brand-new dual glass module. Trina Solar Vertex TSM-DEG21C.20 (670 W) framed dual-glass bifacial module

Why do bifacial modules need 2 mm glass?

As a result of the additional cost of very thin glass, most mass production bifacial modules being produced today are described as using 2 × 2.5 mm glass. More often, this means 3.2 mm on the front and 2 mm backsheet glass, states Weilharter – which brings down costs but in turn introduces its own issues.

What is bifacial glass technology?

Bifacial glass technology is the preferred material among manufacturers for the rear side cover of the modules. Some key advantages of the glass-glass structure are: Glass-glass modules can also be frameless, which helps eliminate the cost of an extruded aluminum frame. However, glass-glass models with frames have a lower risk of breakage.

Do bifacial modules come with frames?

As a result, most glass-glass modules come with frames in place. Compared with standard glass backsheet technology, framed modules with two layers of glass are heavier. Therefore, transparent backsheets are a solution for a lighter bifacial module. A more lightweight module means less cost on transportation, labor, and trackers whenever applicable.

What is a dual glass module?

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the back glass with a unique drilling technique that ensures the reliability of both the junction box installation and the module.

Why are glass-glass bifacial modules becoming more popular?

Due to their better reliability, glass-glass bifacial configurations have a larger portion of the worldwide bifacial module market share. Glass shortages, weight concerns for larger format modules, and decreasing prices for transparent backsheets have caused some manufacturers to switch to a glass-transparent backsheet structure.

Industry Information

- Which is the best micro UPS uninterruptible power supply in Laos

- Mainstream products of energy storage cells

- Harare Home Energy Storage Battery Manufacturing Company

- 3500W Solar Street Light

- Emergency portable UPS power supply

- Which inverter is pure sine wave

- Algeria Industrial Container Wholesale

- Abkhazia 5g base station

- Flow battery working environment

- Bhutan energy storage product exports

- Communication base station inverter procurement service process

- Wind-solar hybrid communication base station system

- Where can I find a 12v inverter in Mauritania

- Recommended energy storage solar panels

- City communication base station battery setting density

- Minimum voltage of 48v lithium battery pack

- 240v circuit breaker in China in Japan

- 48v industrial frequency pure sine inverter

- Pakistan Karachi three phase inverter

- Battery cabinet shockproof baffle base station

- Vientiane outdoor power supply for sale

- Wholesale sf6 circuit breaker in Uae

- Inverter Battery Cabinet Base Station Power Technology

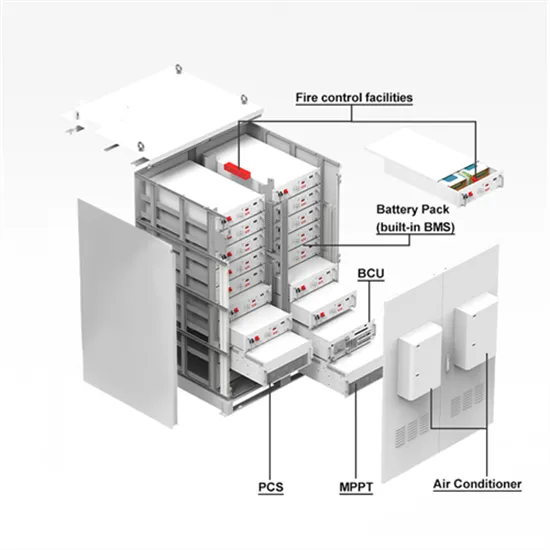

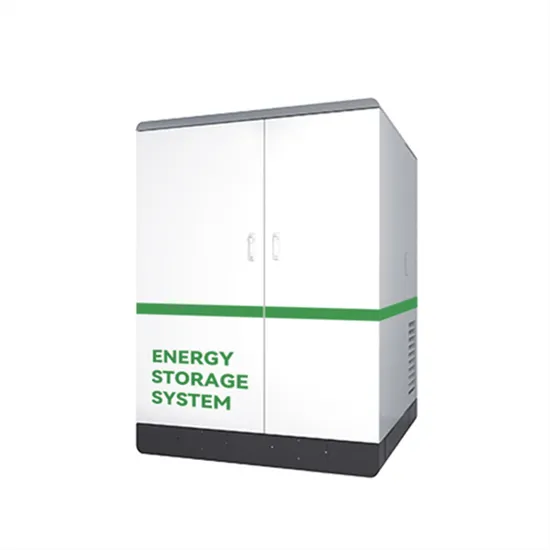

Commercial & Industrial Solar Storage Market Growth

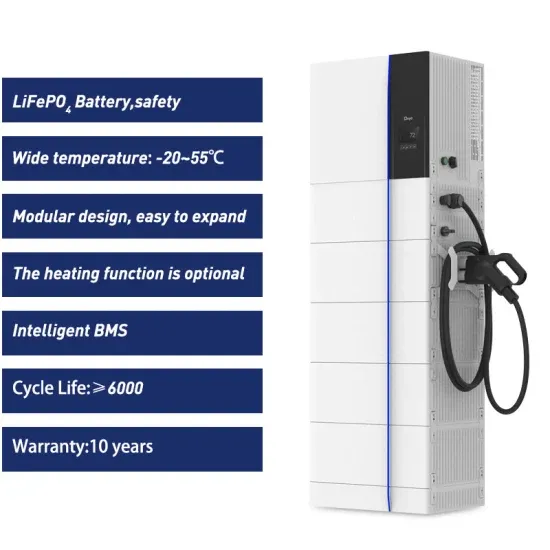

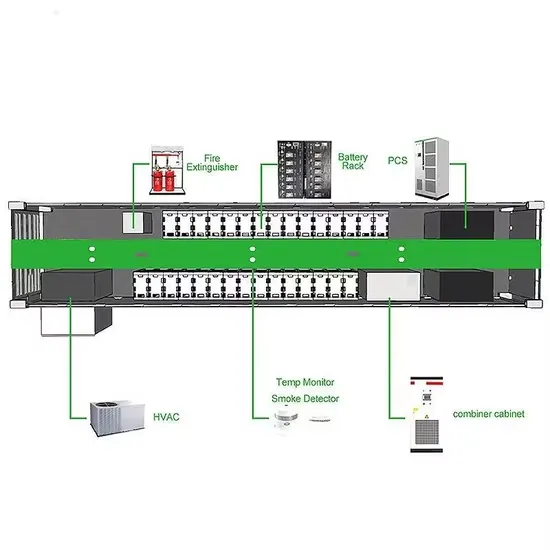

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.