EV design – battery calculation – x-engineer

The high voltage battery it is one of the most important component of a battery electric vehicle (BEV). The battery parameters have a significant influence on

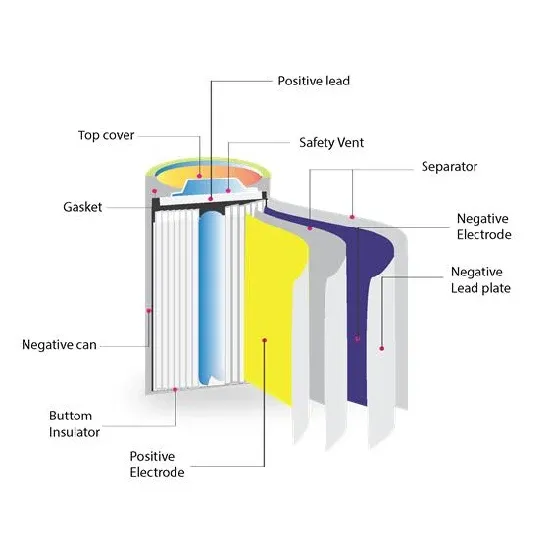

Understanding Cylindrical Lithium-Ion Battery

Feb 19, 2025 · In today''s technology-driven world, cylindrical lithium-ion batteries are more than just a power source—they are a fundamental component in

21700 Battery Specifications: Datasheet and

Here we have listed all the possible technical 21700 battery specifications that can be very useful in executing any technical design of your product or

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Cylindrical batteries can be divided into lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganate batteries, and

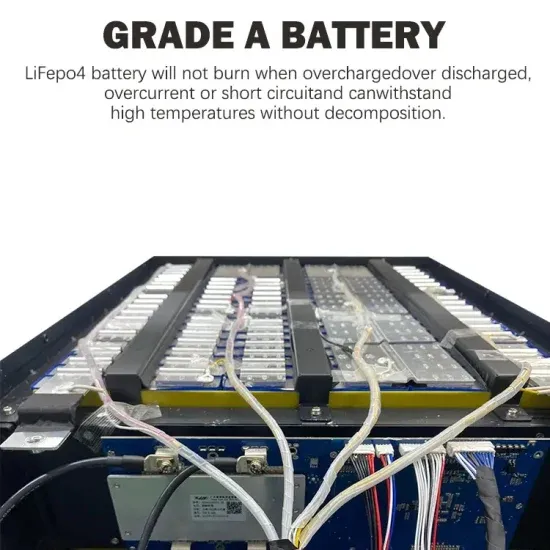

High Safety LFP 26650FS4 4000mAh 3000 Times Long Cycle

High Safety LFP 26650FS4 4000mAh 3000 Times Long Cycle Rechargeable Lithium Cell for Electronic Vehicle Battery Pack Cell

Laos lithium ion NCM 10180 100mAh 3.7V cylindrical battery

We focused on cylindrical lithium-ion batteries for eighteen years. Develop and produce over 90 cylindrical lithium-ion batteries. Nearly 700 employee are dedicated in the factory work place.

Cylindrical lithium battery classification and

May 17, 2023 · The 26650 battery is a lithium battery with a diameter of 26mm and a hidewh of 65mm,with a nominal voltage of 3.2V and a nominal capacity

Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

40AH LTO Lithium Titanate Battery

Aug 1, 2025 · 2.3V 40Ah lithium titanate LTO battery cylindrical cell with more than 25000 cycles, 10C high charge and discharge rate.

Analysis of Cylindrical Lithium Battery Advantages and

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

LiFePO4 Battery Voltage Chart: Your Ultimate

May 11, 2024 · The LiFePO4 voltage chart is key to understanding battery performance and safety. This guide covers essential voltage details and a

21700 3.7V 4000mAh 10C Lithium Ion Battery

1. General Specifications Battery Model: 21700 Lithium Ion Nominal Voltage: 3.7V Nominal Capacity: 4000mAh (4Ah) (at 0.2C Discharge) Internal Resistance:

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

tadzik

Lithium-ion batteries are widely used in a variety of applications, including electric vehicles, energy storage systems, due to their high energy density, long cycle life and low self

Product Specifications Document No: 50/352

Jun 7, 2021 · 1. Scope This document sheet is prepared to specify the technical parameters of the Li Ion cell model 21700 – 5000mah supplied under AMS Batteries.

Laos Cylindrical Li-ion Battery Market (2025-2031) | Outlook

Market Forecast By Product Type (18650 Cylindrical Li-ion Battery, 21700 Cylindrical Li-ion Battery, 26650 Cylindrical Li-ion Battery, 4680 Cylindrical Li-ion Battery), By Technology Type

Lithium Battery Voltage Chart: 3.2V, 3.7V, 4.2V

Jan 4, 2024 · What is a Battery Voltage Chart? A battery voltage chart is a critical tool for understanding how different lithium-ion batteries perform under specific

【New message】Innovative Polymer Battery Solutions

GeB: Your dedicated cylindrical lithium battery manufacturer with 16 years of focus. We provide innovative custom solutions for your unique power requirements.

Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries

Jan 17, 2025 · Significantly, our LHCE-GPE allows for the operation of practical solid-state 18650 cylindrical LMBs at 4.7 V and industrial Li-ion batteries at 4.6 V, achieving high energy

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Understand Minimum and Maximum Voltage for Lithium Batteries

Apr 8, 2025 · The maximum voltage for lithium batteries, such as lithium polymer (LiPo) and lithium-ion (Li-ion) types, is 4.2V. This value is the upper limit to which the battery can be

HANDBOOK Primary Lithium Cells (english)

1. general information the Varta microbattery lithium manganese dioxide cell chemistry was one of the first solid cathode cells commercially developed and is still the most widely used system

Cylindrical Cell-EVE

Cylindrical Cell*Above data comes from EVE''s laboratory. Product performance may differ in different products, please contact us for details.

LG INR 21700 M50

May 5, 2023 · The product data sheet specifies 500 cycles at C/3 charge and C/3 discharge between 4.2V and 2.85V, hence 100% to 0%. The EU collaborative project iModBatt

Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · With the widespread application of electric vehicles, energy storage systems, and portable electronic devices, lithium-ion batteries, particularly cylindrical cells, have become a

Cycle life of cylindrical Li-ion batteries under

Cycle life of cylindrical Li-ion batteries under high charging load conditions at I max = 4.5 C, V max = 4.2 V (a) and I max = 4.5 C, V max = 4.3 V (b). Cycle

Explain Charging and Discharging of Lithium-Ion

Feb 7, 2025 · Learn how lithium-ion batteries charge and discharge, key components, and best practices to extend lifespan. Discover safe charging

HANDBOOK Primary Lithium Cells (english)

May 5, 2016 · Battery Selection In order to ensure optimum battery performance for the primary CR Button, the cylindrical CR High Power and cylindrical High Capacity cells, we suggest

Laos lithium battery voltage

What is lithium ion battery charging voltage? Lithium batteries generally have a nominal voltage higher than 3.0 volts, and are more suitable for integrated circuit power supplies,the rated

THE CURRENT STATUS OF LITHIUM BATTERY COMMERCIALIZATION IN LAOS

Here is a general overview of how the voltage and current change during the charging process of lithium-ion batteries: Voltage Rise and Current Decrease: When you start charging a lithium

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Understanding a Lithium-ion cell datasheet

Dec 21, 2021 · Charge Voltage Cut-off It is the maximum voltage of a cell to which a cell should be charged. The charge voltage cutoff for an LFP cell is 3.60V –

18650 Battery Specifications: Datasheet and

The 18650 battery specification includes its properties like the voltage, capacity, charge-discharge cycle, output current, output voltage and so on. This is a

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

6 FAQs about [Laos cylindrical lithium battery maximum voltage]

What is the power density of a cylindrical lithium battery?

The rated energy density of a single cylindrical lithium battery is between 300 and 500Wh/kg. Its specific power can reach more than 100W. According to different models and specifications of cylindrical batteries, the actual performance of this type of battery varies. 3. Safety and reliability of cylindrical lithium batteries

What are the different types of lithium batteries?

Cylindrical batteries can be divided into lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganate batteries, and cobalt-manganese hybrid batteries based on filler materials. According to the type of shell, cylindrical lithium batteries can be steel shell lithium batteries and polymer shell lithium batteries. Part 1.

Are cylindrical lithium batteries a good choice?

Cylindrical lithium batteries are more suitable for large-volume automated combination production. Large-volume lithium-ion batteries such as electric bicycles and electric motorcycles are basically produced from cylindrical lithium batteries. Not only that, cylindrical lithium batteries are also recognized as green and healthy batteries.

What is a cylindrical lithium battery?

The cylindrical battery shell has high voltage resistance and will not cause swelling of square or soft-packaged batteries during use. The cylindrical lithium battery cell size is larger. When the current is discharged, the internal temperature of the winding core is relatively high.

What is the discharge capacity of Li lhce GPE ncm811 batteries?

At an increased cut-off voltage of 4.6 V, Li|LHCE-GPE|NCM811 batteries achieve a higher discharge capacity of 217.7 mAh g −1, maintaining 69% capacity retention after 200 cycles (Fig. S11).

Are LMA batteries safe?

High capacity (ampere-hour scale) pouch cells and cylindrical batteries incorporating LMA are susceptible to electrolyte leakage and potential ignition under mechanical abuse conditions, such as penetration and shearing, presenting significant safety risks in practical applications.

Industry Information

- Two degrees of electricity outdoor power supply Xiaomi

- Correct installation of Cuban solar pump

- Civilian grid-connected inverter

- Buy outdoor power supply in Congo

- How much does the Funafuti energy storage power supply cost

- Four sets of 12v batteries with inverter

- Energy storage power station operation and maintenance focus

- Outdoor generators and outdoor power supplies

- Solar Container Energy Storage Specialty Store

- Dublin rechargeable energy storage battery manufacturer

- Huawei Libya energy storage pack price

- Small container stations from Kuwait City to Rong Energy

- South America Solar System Wholesale

- Guyana lithium battery energy storage battery cabinet

- Large-scale photovoltaic power station inverter

- Bangladesh Vanadium Liquid Flow Battery Energy Storage Electricity

- UPS battery cabinet c12 size

- Huawei communication base station inverter photovoltaic power generation

- Large capacity and long time storage solar lamp

- China vacuum circuit breaker in Sao-Paulo

- Battery cabinet base station energy impact current

- Wind power generation smart system

- Energy storage trial power generation

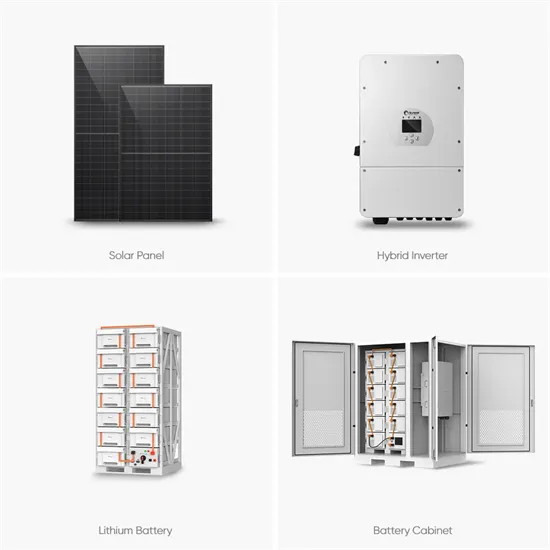

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.