Cylindrical Cell Manufacturing Equipment Solutions | Targray

Aug 16, 2025 · Cylindrical Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge

EV Car Battery Assembly,Electric Bike Battery Assembly

We also supply all kinds of EV Car Battery Assembly,Electric Bike Battery Assembly for you! We can assure our customers of our products with high quality,best services and a reasonable price.

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Cylindrical Lithium Battery Pack Assembly Plant Equipments

Tmax is a professional Cylindrical Lithium Battery Pack Assembly Plant Equipments for EV Bike/Energy Storage/ Solar Light Battery Assembly,Battery Pack Assembly Plant supplier from

Batterymaking : Lithium Ion Battery

Tmax is a battery manufacturing equipment and Li ion battery materials supplier with over 20 years of Lithium Ion battery industry experience and professional

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

Lithium Battery Equipment | Battery Manufacturing Machines | Battery

Commercial manufacturing and R&D lithium battery equipment solutions,and battery assembly equipment manufacturers. Vast selection of in stock battery manufacturing machines to

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

Lithium ion Battery Pack Assembly Line Making

Cylindrical battery pack assembly line machine is suitable for all kinds of cylindrical battery pack making according to customer''s requirement.

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Unraveling the Mysteries of Cylindrical Cell

Jun 22, 2025 · This guide aims to provide a comprehensive overview of cylindrical cell assembly, tailored for those new to the subject. Cylindrical cells are

Cylindrical Cell manufacturing line

Apr 11, 2025 · A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries. It combines specialized machinery, automation

Unraveling the Mysteries of Cylindrical Cell

Jun 22, 2025 · Cylindrical lithium-ion cells are integral to powering a vast array of devices, from smartphones to electric vehicles. Understanding the assembly

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Cylindrical lithium-ion batteries are widely used in consumer electronics, electric vehicles, and energy storage applications. However,

Cylindrical Cell Assembly Line

Oct 8, 2024 · A cylindrical cell assembly line is a highly automated production system designed to manufacture cylindrical battery cells,commonly used in applications such as electric vehicles

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · Electrode manufacturing Cell assembly Cell finishing The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell

Lithium-ion Cylindrical Cell Manufacturing Process

Jul 25, 2023 · In this article, we will describe the production process of lithium-ion cylindrical batteries in detail. 1. Lithium-ion Battery Material Preparation. The

Exploring Assembly and Testing of Cylindrical

Nov 15, 2024 · Explore the assembly and testing of cylindrical batteries, their unique design, applications, and advantages in energy storage and electric

Battery Form Factors: Cylindrical, Prismatic

Nov 15, 2024 · Compare battery form factors and understand the pros and cons of cylindrical, prismatic, and pouch lithium-ion batteries for EVs, electronics,

How To Assembly Cylindrical Battery Pack?

How To Assembly Cylindrical Battery Pack?1) Product Description The lithium-ion battery sorter is used to sort the internal resistance and voltage of cylindrical

Cylindrical Battery Assembly: A Simple Guide (2024 Update)

Simply put, cylindrical battery assembly involves connecting multiple individual cylindrical cells (like common AA or AAA batteries) to create a larger battery pack. This pack can provide

Cylindrical Cell manufacturing line

Apr 11, 2025 · What is a Cylindrical Cell Manufacturing Line? A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries.

Unraveling the Mysteries of Cylindrical Cell

Mar 24, 2025 · Cylindrical lithium-ion cells are integral to powering a vast array of devices, from smartphones to electric vehicles. Understanding the assembly

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Automated Assembly Line for Large and Small

Discover our automated assembly line tailored for 32135/40140 cylindrical lithium batteries, featuring high automation, precision, and compatibility. With key

Cylinder Cell Battery Pack Assembling Line

Lithium battery PACK assembly line for energy storage battery manufacturer The system integrates a lithium battery sticker system, a sorting and inspection

Exploring Assembly and Testing of Cylindrical

Nov 15, 2024 · At ATS Industrial Automation, we have delivered over 110 EV battery assembly and test lines and understand the challenges of designing

6 FAQs about [Cylindrical lithium battery assembly]

What is a cylindrical lithium ion battery?

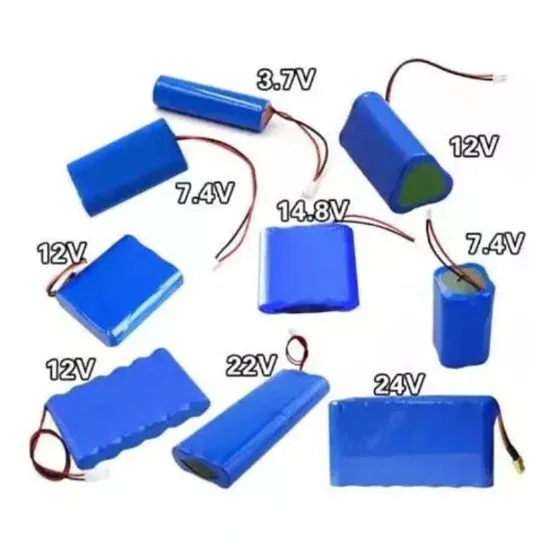

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

What is a cylindrical lithium-ion cell?

Cylindrical lithium-ion cells are integral to powering a vast array of devices, from smartphones to electric vehicles. Understanding the assembly process of these cells not only demystifies the technology but also highlights the precision and innovation involved in their creation.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

What is a cylindrical battery?

Known for their reliability, efficiency, and versatility, cylindrical batteries have become a critical component in grid-scale battery energy storage systems (BESS). What sets these cells apart from other battery types is their rigid cylindrical structure, which enables efficient packing and cooling.

How are cylindrical lithium-ion cells produced?

The production of cylindrical lithium-ion cells involves several meticulously controlled steps to ensure quality and performance. The primary stages include electrode preparation, cell assembly, electrolyte filling, formation, and testing. 1. Electrode Preparation

Industry Information

- Inverter reverse connection 220

- Hybrid Energy Communication Base Station Distributed Power Generation Panel

- Albania 12v ups uninterruptible power supply

- Naypyidaw Gigawatt Solar Project

- 33kW PV inverter

- Photovoltaic inverter terminal

- Dushanbe UPS uninterruptible power supply 6kw

- Application of Silicon Carbide in Photovoltaic Inverters

- Hungarian Crystalline Silicon Photovoltaic Curtain Wall Company

- Oman automotive photovoltaic module prices

- North Korea s 4 2-meter solar air conditioner

- Huawei Swaziland Liquid Cooling Energy Storage

- N Djamena energy storage system connected to the grid

- What is the price of Portonovo s energy storage container

- Factory price current breaker in Pretoria

- PCS lithium battery inverter design

- Single-phase energy storage product

- 420w photovoltaic panel size

- Service life of power storage box

- Japan Energy Storage Container Sales

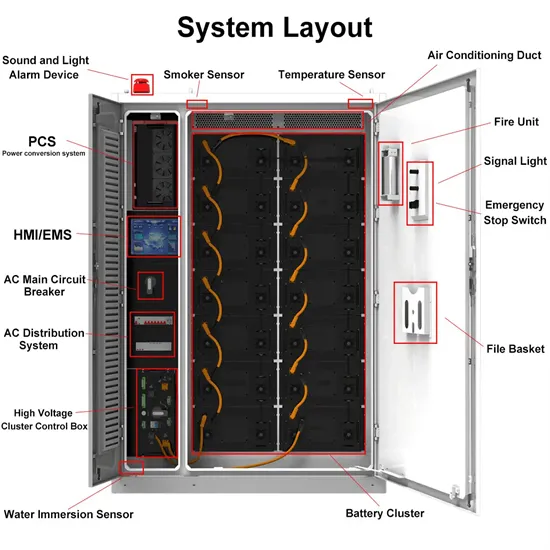

- Battery energy storage main accessories

- Victoria Fiber Optic Energy Storage Battery

- Which brand of battery energy storage is good in Busan South Korea

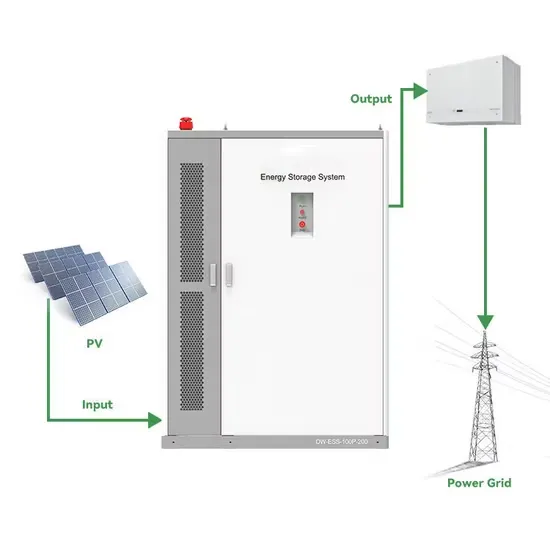

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.