Analysis of Smoke Composition and Toxicity from

Feb 10, 2025 · Demand for greater storage capacity and pack voltage has driven advancements in cell design and materials research, as these improvements increase battery run time and

Upcycling and recycling of spent battery waste for a

Upcycling spent battery waste materials into graphene and catalysts is explored. Bioleaching and deep eutectic solvents are reviewed for sustainable LIB recovery. Restoration and

A Deep Dive into Spent Lithium-Ion Batteries: from

Oct 30, 2024 · Retired lithium-ion batteries are rich in metal, which easily causes environmental hazards and resource scarcity problems. The appropriate disposal of retired LIBs is a pressing

Sustainable Recycling of Lithium-Ion Battery Cathodes: Life

5 days ago · Rapid growth of electric vehicles has increased demand for lithium-ion batteries (LIBs), raising concerns regarding their end-of-life management. This study comprehensively

Understanding materials failure mechanisms for the

Mar 20, 2025 · The stock is divided into plug-in hybrid EVs and battery EVs. b, Average pack price of lithium-ion batteries and share of cost for cathode material, between 2011 and 2021.

Analytical and structural characterization of waste lithium

Jan 1, 2025 · Additionally, the NaCl solution neutralizes reactive lithium residues by forming stable compounds like lithium hydroxide, ensuring safer handling. Unlike nichrome wire, which

Lithium Battery NMP Recovery and Purification

Jan 23, 2025 · The NMP (N-methyl-2-pyrrolidone) recovery and purification segment for lithium battery manufacturing is dominated by a mix of established chemical engineering firms and

Processing Battery Black Mass at End of Life

Oct 1, 2023 · Processing battery black mass remains a challenge, because unlike lead-acid batteries, lithium-ion cells do not dismantle easily. Reducing End-of

Lithium-Ion Battery Recycling Frequently Asked Questions

Aug 6, 2025 · Are lithium batteries hazardous waste? When they are disposed of, most lithium-ion (secondary batteries) and lithium primary batteries in use today are likely to be hazardous

A review of lithium-ion battery recycling for enabling a

Feb 28, 2025 · With the rapid electrification of society, the looming prospect of a substantial accumulation of spent lithium-ion batteries (LIBs) within the next decade is both thought

Toxic fluoride gas emissions from lithium-ion battery fires

Abstract Lithium-ion battery fires generate intense heat and considerable amounts of gas and smoke. Although the emission of toxic gases can be a larger threat than the heat, the

Spotlight on: Health risks from gases released in

Sep 12, 2023 · Fire is not the only danger with lithium-ion batteries. Here''s what risk managers need to know, and how to manage the threats

Inhibiting and rejuvenating dead lithium in battery materials

Jun 2, 2025 · Rechargeable lithium (Li) battery chemistry has been widely adopted in modern society, and the unstoppable desire for higher energy density has promoted the development

Methodology for evaluation of lithium-ion black-mass battery

Feb 6, 2025 · To validate result confidence, eight tests were conducted on a synthetic material, akin to black-mass lithium-ion batteries, encompassing nickel oxides, manganese oxide,

Contaminations from Lithium-Ion Battery Fires—Per

Mar 26, 2025 · Fluorinated substances are widely used in the different components of the lithium-ion battery cell, such as electrode binders, electrolyte, additives and separator materials. To

Unraveling the Intricacies of Residual Lithium in

Feb 12, 2021 · High-nickel layered oxide cathodes suffer seriously from the formation of residual lithium on the surface, which causes notorious issues,

Lithium-Ion Battery Fire and Explosion Hazards

Jan 27, 2023 · Lithium-ion battery-powered devices — like cell phones, laptops, toothbrushes, power tools, electric vehicles and scooters — are everywhere.

Lithium-Ion Battery Leaks: Safety & Prevention Guide

Jul 29, 2025 · A bulging phone case, a warped power tool, or a strange, sweet chemical smell from your favorite gadget—these are the signs of a lithium-ion battery leak. Unlike the crusty

Challenges in Recycling Spent Lithium‐Ion

It is critical to separate cathode materials and Al foil and recycle PVDF to reduce environmental risks from the recovery of retired LIBs resources. Developing

The battery is like a living entity, we produce

EVE Energy Co., Ltd.The battery is like a living entity, we produce them with uncompromised respect and dignity.

An In-depth Look at The Black Mass Recovery

Black Mass is a term used in the battery recycling industry to describe the output of the process of liberating and concentrating battery-active materials. This

Detailed Characterization of Thermal Runaway Particle

Jun 9, 2025 · Particles ejected during thermal runaway (TR) of lithium-ion batteries carry a significant fraction of the total TR energy and can cause danger to other components in the

Life-Cycle Analysis for Lithium-Ion Battery Production and

May 19, 2025 · Explore the full lithium-ion battery life-cycle—from material sourcing and battery performance analysis to battery degradation testing, recycling, and lithium battery material

Formation mechanism and removal strategy of residual lithium

Dec 1, 2024 · As a result, surface residual lithium compounds Ni-rich cathode materials will reduce their comprehensive properties, complicate the subsequent electrode manufacturing

What is black mass in a lithium-ion battery

Jul 26, 2024 · Definition and Components of Black Mass Black mass is a key component separated during the recycling process of lithium-ion batteries,

Cost modelling and key drivers in lithium-ion battery recycling

Aug 8, 2025 · As the use of lithium-ion batteries continues to grow, cost-effective battery recycling becomes essential, yet recycling cost models often overlook key factors such as transport and

Designing lithium-ion batteries for recycle: The role of

Jun 1, 2023 · Moves to make the battery pack a structural element of the vehicle have led to an increased use in structural adhesives and permanent welds to increase pack rigidity. For

Thermal runaway procedure and residue analysis of LiFePO

Feb 5, 2024 · The frequent occurrence of thermal runaway accidents of lithium-ion batteries has seriously hindered their large-scale application in new energy vehicles and energy storage

The Lithium-Ion (EV) battery market and supply chain

Apr 5, 2022 · Drivers for Lithium-Ion battery and materials demand: Large cost reduction expectations Indicative, Jul. ''21 cell costs Costs can likely be reduced by USD 30-40 / kWh

Adhesive bonding in automotive battery pack manufacturing

Jun 18, 2025 · The integration of electric vehicles (EVs) powered by lithium-ion batteries (LIBs) marks a pivotal phase towards achieving a net-zero environment. The anticipated surge in EV

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Automated remanufacturing of lithium-ion batteries with

Jan 1, 2023 · Lithium-ion battery (LIB) remanufacturing holds great potential for CO 2 savings, but there are challenges to productive disassembly. The demand to increase productivity in LIB

Recycling of Primary Lithium Batteries Production Residues

Mar 3, 2021 · Production waste of primary lithium batteries constitutes a considerable secondary lithium feedstock. Although the recycling of lithium batteries is a widely studied field of

A Pathway to Circular Economy-Converting Li-Ion Battery

Apr 21, 2025 · This study highlights the successful valorization of black mass leach residue—a by-product of lithium-ion battery recycling—as a promising precursor for electrocatalyst synthesis.

A Deep Dive into Spent Lithium-Ion Batteries: from

Oct 30, 2024 · The lithium-ion battery system utilized in electric vehicles comprises a battery pack and a battery management system (BMS). The initial step of cascade utilization involves the

6 FAQs about [Lithium battery pack residue]

Are lithium-ion batteries recyclable?

As the global deployment of lithium-ion batteries (LIBs) accelerates, efficient and cost-effective recycling strategies are becoming critical to ensure material circularity and supply security. However, although the technical principles of LIB recycling are broadly understood, the economic modelling of recycling processes remains fragmented.

What is the recycling process for lithium ion batteries?

The overall direct recycling process for spent lithium-ion batteries: Route 1 from huge batteries; Route 2, black mass. The development of the recycling of batteries depends strongly on the current regulations and the medium and long-term needs in materials.

How to recycle retired lithium-ion batteries?

In the recycling of retired lithium-ion batteries (LIBs), the cathode materials containing valuable metals should be first separated from the current collector aluminum foil to decrease the difficulty and complexity in the subsequent metal extraction.

How to recover cathode materials from waste lithium-ion batteries?

Wang et al. used mechanical crushing and size separation to recover cathode materials from waste lithium-ion batteries, including LiCoO 2, LiFePO 4, LiMn 2 O 4, and mixed-metal cathode LIBs.

Are retired lithium-ion batteries a problem?

Retired lithium-ion batteries are rich in metal, which easily causes environmental hazards and resource scarcity problems. The appropriate disposal of retired LIBs is a pressing issue. Echelon utilization and electrode material recycling are considered the two key solutions to addressing these challenges.

Can lithium-ion battery cathodes be recycled?

Yu, X. et al. Achieving low-temperature hydrothermal relithiation by redox mediation for direct recycling of spent lithium-ion battery cathodes. Energy Storage Mater. 51, 54–62 (2022). Yang, T. et al. An effective relithiation process for recycling lithium‐ion battery cathode materials.

Industry Information

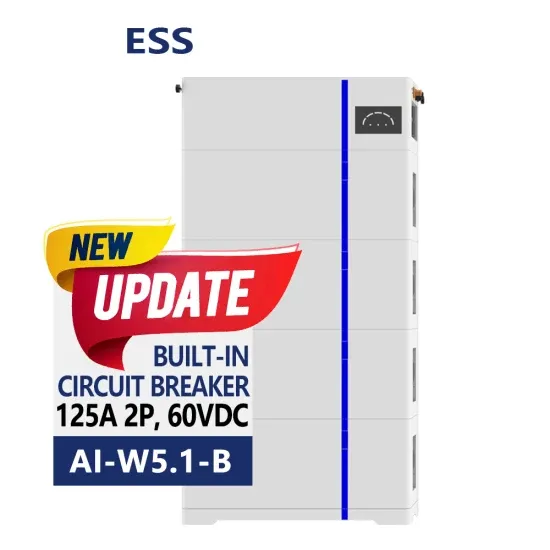

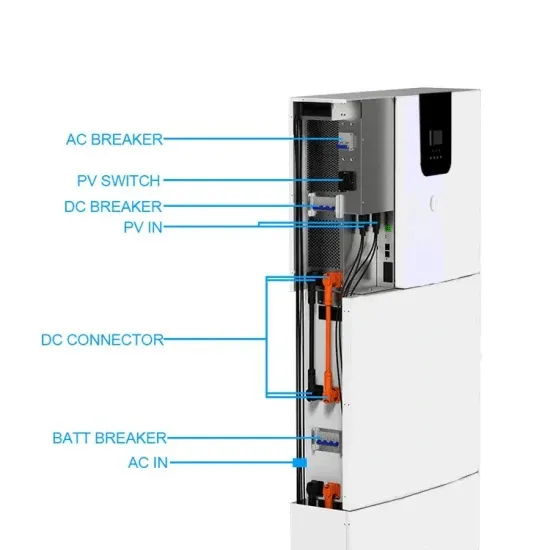

- Adaptation of battery energy storage system for communication base stations

- Off-grid energy storage power station solar lithium battery

- Commonly used batteries for energy storage power supply

- Baku Communication Energy Storage Installation Base Station

- Battery power system bms

- Slovenia Photovoltaic Energy Storage

- Energy storage cabinet belongs to the industry

- How much energy storage should be matched with 1GW of photovoltaic power generation

- Cheap wholesale 12v circuit breaker exporter

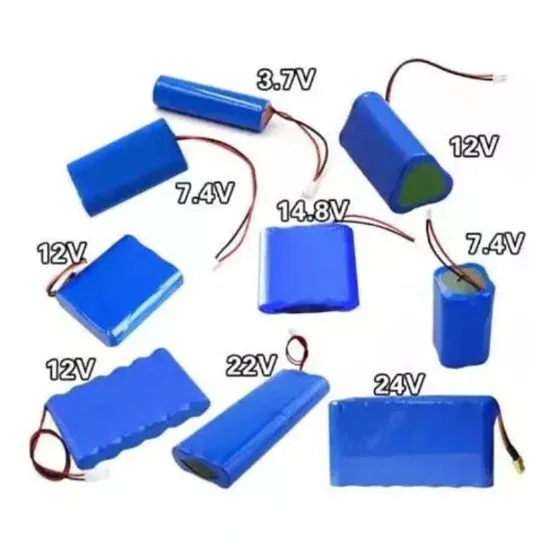

- Cylindrical lithium battery composition

- Photovoltaic grid-connected system and off-grid system

- Dushanbe with solar air conditioner

- Is it necessary to install photovoltaic energy storage in villas

- 330W solar panel size

- Djibouti Industrial Energy Storage Cabinet Manufacturer

- Which UPS is the best in London

- Czech outdoor wind power base station environmental protection electricity

- Maseru power generation side energy storage project

- Charging station energy storage equipment cost

- Is there a place for battery cabinets in Niger

- Comparatively cheap outdoor power supply brands

- Best factory price single breaker for sale

- Kampala Photovoltaic Energy Storage Fire Extinguishing Manufacturer

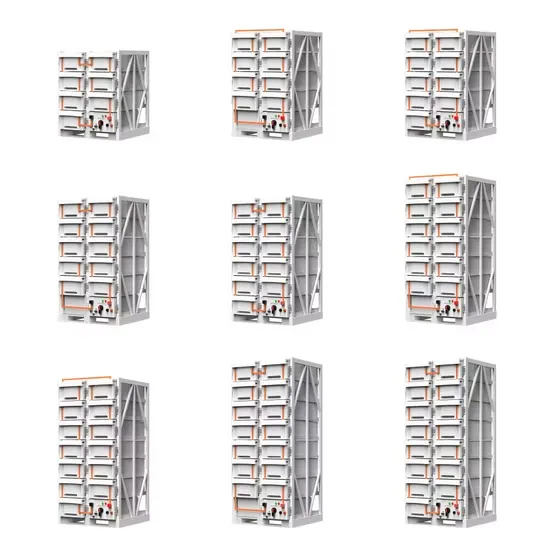

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.