Unlocking the Future: Understanding the EV Charging Pile

Jan 3, 2025 · What is an EV Charging Pile? Electric Vehicle Charging Piles, also called electric vehicle charging stations, consist of electromechanical devices that provide electric energy to

A complete list of energy storage charging pile model

Aiming at the charging demand of electric vehicles, an improved genetic algorithm is proposed to optimize the energy storage charging piles optimization scheme.

Design and Application of Smart EV Charging Piles

Jun 24, 2025 · The integration of V2G, energy storage technologies, and high-performance batteries not only facilitates battery swapping services but also drives the convergence of

AC Level 2 Charger Platform Reference Design

Dec 29, 2022 · An EVSE control system consists of an auxiliary power stage, an off-board AC/DC high-power stage (only in DC charging stations), energy metering unit, AC and DC residual

Flexible energy storage charging pile

The whole system consists of photovoltaic power generation, charging piles, energy storage parts, etc., including photovoltaic power installation 800kW, energy storage installed 13MWh, DC

Ac energy storage charging pile

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Charging pile with energy storage battery

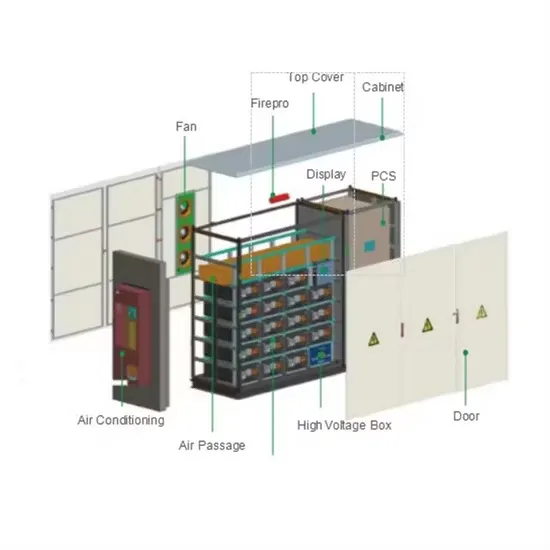

Absen''''s Pile S is an all-in-one energy storage system integrating battery, inverter, charging, discharging, and Page 1/4 Charging pile with energy storage battery intelligent control. It can

180kW丨240kW Integrated DC Charging Pile

Intelligent high-reliability DC charging pile is tailor-made for commercial vehicle charging. The charging module adopts high-protection full-filling glue technology, which has strong

AC Charging Piles: Benefits, Drawbacks, and Real-World Impact

AC charging allows for faster charging of large vehicles, making it ideal for scenarios where bulk charging is necessary. Unlike DC charging, AC charging piles can charge multiple vehicles

Presentation title on multiple lines

Dec 14, 2020 · SiC based AC/DC Solution for Charging Station and Energy Storage Applications JIANG Tianyang Industrial Power & Energy Competence Center Region, STMicroelectronics

Presentation title on multiple lines

Dec 14, 2020 · SiC based AC/DC Solution for Charging Station and Energy Storage Applications JIANG Tianyang Industrial Power & Energy Competence Center Region, STMicroelectronics

Comparative Analysis: AC, DC, and Energy

Energy storage charging piles combine photovoltaic power generation and energy storage systems, enabling self-generation and self-use of photovoltaic power,

Unplugging Uncertainty: Answering ''What is an

Jun 22, 2024 · A key component in this space is the Electric Vehicle Charging Pile or EV charging pile. So, what is an EV charging pile? Simply put, an EV

Technology and classification of charging piles

Mar 2, 2023 · Charging pile refers to a charging device that provides energy supplement for electric vehicles. Its function is similar to that of a fuel

The Design of Electric Vehicle Charging Pile Energy

Apr 27, 2017 · The structure diagram and control principle of the sys-tem are given. The electric vehicle charging pile can realize the fast charging of electric vehicles, and the battery of the

Understanding the Charging Pile: The Future of

Feb 10, 2025 · What is a Charging Pile? An EV charger or charging pile is a unit intended for supplying electric energy to an electric vehicle that requires

The difference between new energy DC charging

Dec 15, 2022 · Difference between DC and AC Charger. AC charging pile, commonly known as "slow charging", is a power supply device installed

Energy storage can be ac ​​charging pile

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system .

Energy storage charging pile line factory

Saiter portable American standard DC charging pile (machine) field tester ST-9980UA-DC, is a device with interoperability testing can be widely used in the research and development of DC

How to connect the energy storage charging pile interface

The DC energy meter can read user information through the RS485 communication interface and monitor the charging status according to user needs. The energy detection software can

New energy storage charging pile high voltage failure

Saiter portable American standard DC charging pile (machine) field tester ST-9980UA-DC, is a device with interoperability testing can be widely used in the research and development of DC

EV charging piles (equipment)The Essentials of

They directly use 110V or 240V American standard voltage, European standard 230V400 power supply method, and Chinese 240V voltage. The charging

A Novel High-Power Density and Low Conduction Loss Bidirectional AC/DC

Oct 5, 2023 · A Novel High-Power Density and Low Conduction Loss Bidirectional AC/DC Charging Pile Scheme With Hybrid Charge–Discharge Control Strategy Published in: IEEE

Energy storage fast charging pile structure

Smart photovoltaic energy storage charging pile is a new type of energy management mode, which is of great significance to promoting the development of new energy, optimizing the

Energy storage charging pile standards

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

New energy storage charging pile air tightness tester

AST-9000C of charging pile mobile test platform At present, the on-site testing requirements for AC/DC charging piles can be roughly divided into on-site testing items required by the national

Energy storage charging pile inspection and maintenance

Saiter portable American standard DC charging pile (machine) field tester ST-9980UA-DC, is a device with interoperability testing can be widely used in the research and development of

photovoltaic energy storage charging pile application

A DC Charging Pile for New Energy Electric Vehicles This DC charging pile and its control technology provide some technical guarantee for the application of new energy electric

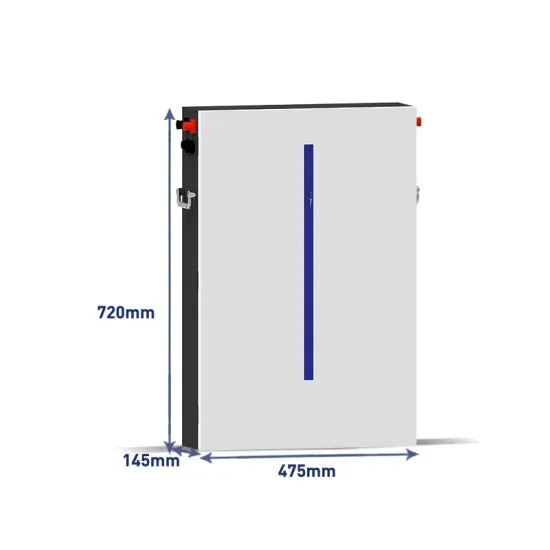

Standard dimensions of energy storage charging pile box

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system .

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Understanding Electric Vehicle Charging Piles: Common

Sep 13, 2024 · Common indicators and functional descriptions of electric vehicle charging piles [Simple principle Before explaining the various indicators, it is necessary to briefly understand

EV Charger Manufacturer/Supplier, EV Charger

6 days ago · Various product SCU, a DC fast charger supplier, is based on strong power electronic technology and digital control technology and independently

American-Standard Energy Charging Pile Portable AC EV Charger

Aug 8, 2025 · We have a suit of comprehensive industrial chains integrating the R&D, design and manufacturing of Electric vehicle charging station and also power storage such as AC/DC EV

3 FAQs about [American Standard AC DC Charging Pile Energy Storage]

What is the difference between AC and DC charging piles?

AC charging piles excel in bulk charging scenarios, such as in bulk storage facilities, while DC charging is more suitable for individual vehicles and fast-charging stations. A table summarizing these differences can help users understand when AC charging piles are most appropriate.

What is an AC charging pile?

Understanding AC Charging Piles AC charging piles operate on alternating current (AC) technology, which differs from the direct current (DC) used in many other charging solutions. This technology is particularly suited for charging electric buses, taxis, and other EVs that require high power outputs.

Why should you use AC charging piles?

AC charging allows for faster charging of large vehicles, making it ideal for scenarios where bulk charging is necessary. Unlike DC charging, AC charging piles can charge multiple vehicles simultaneously, enhancing efficiency in commercial and public transportation settings. Benefits of AC Charging Piles

Industry Information

- What is the wind-solar hybrid system

- Brazil s first photovoltaic energy storage project

- Gaborone home ups uninterruptible power supply

- What lithium battery station cabinets are there in Seychelles

- Base station photovoltaic energy storage price

- Swaziland Energy Storage Inverter R

- LED lighting solar lights

- How to install small solar energy in communication base station

- Energy storage cabinet installation test

- Price of liquid cooling for energy storage station

- Wholesale battery and storage in Ireland

- Iran lead-acid energy storage battery price

- How to join the site energy battery cabinet

- Libya outdoor power bms manufacturer

- Battery discharge construction for communication base station

- Moroni Rural Off-Grid Energy Storage Power Station

- Energy storage equipment photovoltaic project

- Home circuit breaker for sale in Sweden

- Pakistan Karachi Micro Inverter Inverter Standard

- Which is better BMS or battery structure

- Niamey energy storage lithium battery manufacturer quotation

- Bahamas Solar Battery Storage

- BESS type solar power generation system

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.